TB 43-0213

TA504779

Cleaning Procedures.

4-3.

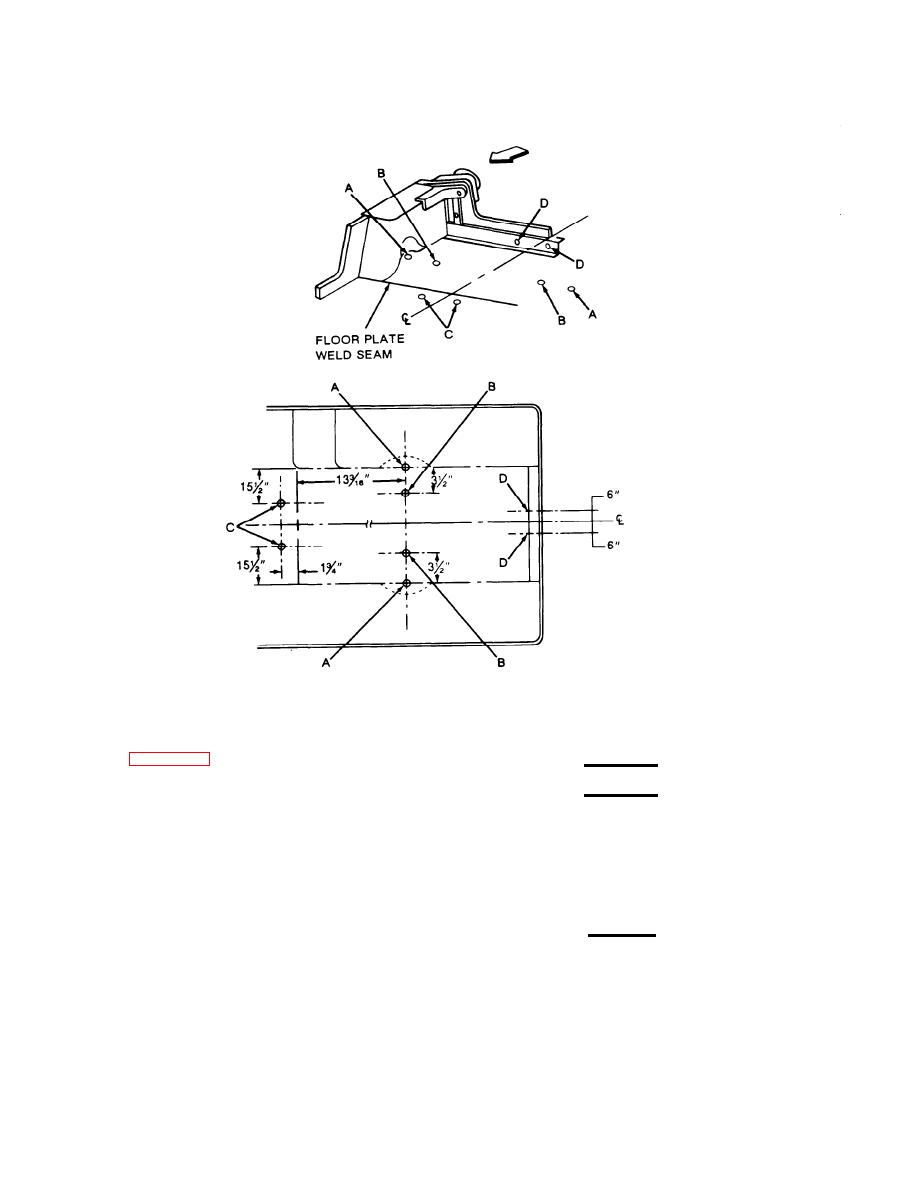

i. Drilling Underbody (M151A2, M718A1 and

M825) (see Figure 4-9).

WARNING

(1) Drill all holes as shown.

When cleaning, water may be discharged in

(2) Holes V and W will penetrate two layers of

excess of 1200 psi (8274 kPa) from high

metal on the M151A2 and the M718A1. They will

pressure water equipment. Serious injury

penetrate only one layer on the M825 due to the rear

could result. Eye protection must be worn

cargo reinforcement having been removed.

to prevent injury.

(3) Two holes X are visually located on the

CAUTION

bottom surface of the rear crossmember, directly in line

with the outer bolts for the rear bumper guards.

Steam cleaning will not be used.

(4) Holes D and F are drilled in the rear facing

a. Wash the interior of framerail structures through

edge of the front crossmember. They are drilled about

drilled access holes to remove mud, dirt, and rust. Use

1 inch (2.5 cm) from the angles.

of a high pressure washer will facilitate this process.

Observe the water flushed through the rails to

(5) Holes Y and Z are drilled at the bottom of

determine when the structure is clean.

the inner and outer suspension arm brackets.

4-4