TM 43-0139

Lay a sheet of smooth wrapping paper on a flat table, placing the silk screen frame on top with the film side down. Soak a

cloth with lacquer thinner and wipe over the film portions of the screen while keeping the rag well saturated. After the

lacquer has softened, pull the paper and the attached film away from the silk screen. Use several clean cloths to

alternately wash the old lacquer from the silk screen. Dry the silk with a soft cloth.

g.

Facts Pertinent to the Silk Screen Printing Process.

(1)

When a job is to be repeated at frequent intervals, the silkscreen frames, with cut film applied, may be

stored for future use.

(2)

In the handling and storage of silk screen frames, care must be exercised to avoid stretching or puncturing

the silk.

(3)

, an average of 5,000 to 10,000 impressions may be made before the silk wears out.

(4)

Experience will indicate the proper consistency at which the paint should be applied. Because solvent

continually evaporates, it is customary to have the replenishing paint slightly thinner than the first portion put into the

screen. This procedure brings the consistency of the paint back to that desired immediately after replenishment.

(5)

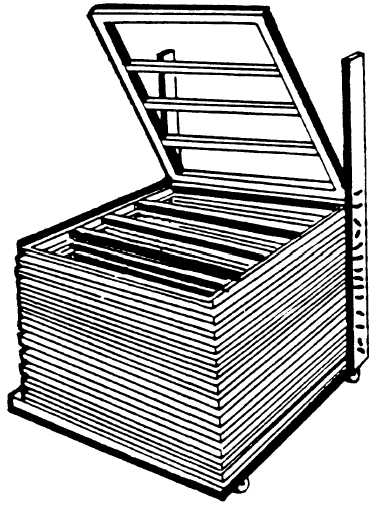

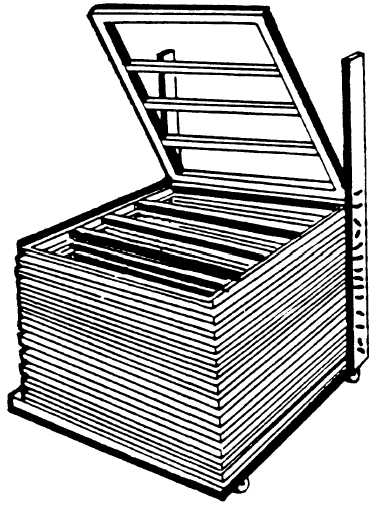

There are various types of space-saving drying racks employed in silk screening. Figure 6-10 illustrates a

typical unit.

Figure 6-10. Drying Rack

6-21/(6-22 blank)