TM 43-0139

f.

Masking. When spraying, cover or mask all parts such as windows, gages, lubrication fittings, instruments, and

other parts which are not to be painted.

(1)

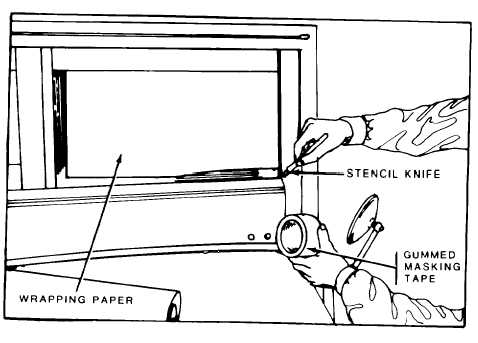

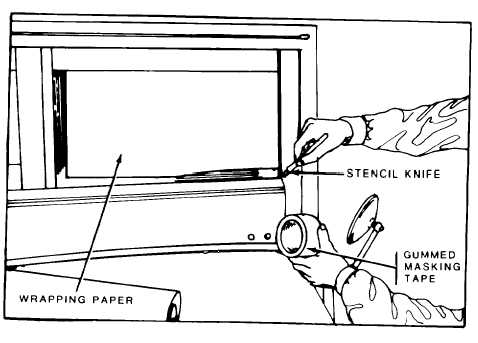

Small areas or irregular-shaped parts are covered with crepe-backed masking tape. On larger areas, a

sheet of paper slightly smaller than the part to be masked is used, with the paper being held in place by a srip of masking

tape, which overlaps the edge of the paper, and holds the paper to the surface being masked. Masking tape is available

in various widths and is a convenient material with which to work when covering irregular outlines. The method of

applying and trimming the tape is shown in figure 5-4.

(2)

Liquid or past-like materials are also available to mask out areas where paint is not desired. After the paint

is dry, these areas may be wiped or stripped clean.

(3)

When spraying vehicle engines, the use of cloth bandages and socks will protect rubber hose, ignition

wires, and flexible tubing, and save much time and material. Cut the cloth bandage to fit the object to be covered,

allowing for hose clamps and other parts of the engine. Drawstrings at each end, with a string wrapped around the middle

of the bandage and tucked under a flap, prevent overspray from striking the protected object. Fit the sock over the

ignition wires and distributor cap, and use the drawstring tie to secure it around the base of the distributor.

5-5. LEAKAGE AND CORRECTION

a.

Material Leakage from Fluid Needle Packing Nut. This condition is caused by a loose packing nut or by dry fluid

needle packing. To remedy, remove and soften the packing with a few drops of light oil. Re-install and tighten packing

nut to prevent leakage. See figures 5-5 and 5-6.

Figure 5-4. Masking

5-6