TM 5-6640-212-14

maintained to plus or minus 1 degree F (-17 degrees C)

(2) Fill the bath to the required level with water or

within the range of 75 degrees F to 200 degrees F (24

light oil.

degrees C to 93 degrees C). A motorized stirrer

(3) Set the thermo regulator as required and apply

provides efficient circulation. The center of the cover has

power to the apparatus.

a fitted 1000-milliliter graduated cylinder of specified

(4) Place both the line switch and the auxiliary heat

dimensions. A rubber stopped supports the diffusion

switch in the ON position.

stone assembly (stored in drawer C2, figs. 1-2 and B-9)

(5) In a low-temperature test, place the auxiliary

which is connected to a calibrated flowmeter with a

heat in the OFF position when the test temperature is

needle valve for maintaining an air flow rate of 94

reached.

milliliter plus or minus 5 milliliter per minute.

(6) In a high temperature test, leave the auxiliary

Thermoregulator used with the apparatus is stored in

heat switch in the ON position after the test temperature

drawer C5 (fig. B-9).

is reached.

b. Operation.

(7) Refer to ASTM Method D892 (TM 10-1166) for

(1) Set the bath on the counter.

detailed testing procedures.

TS 6640-212-14/2-33

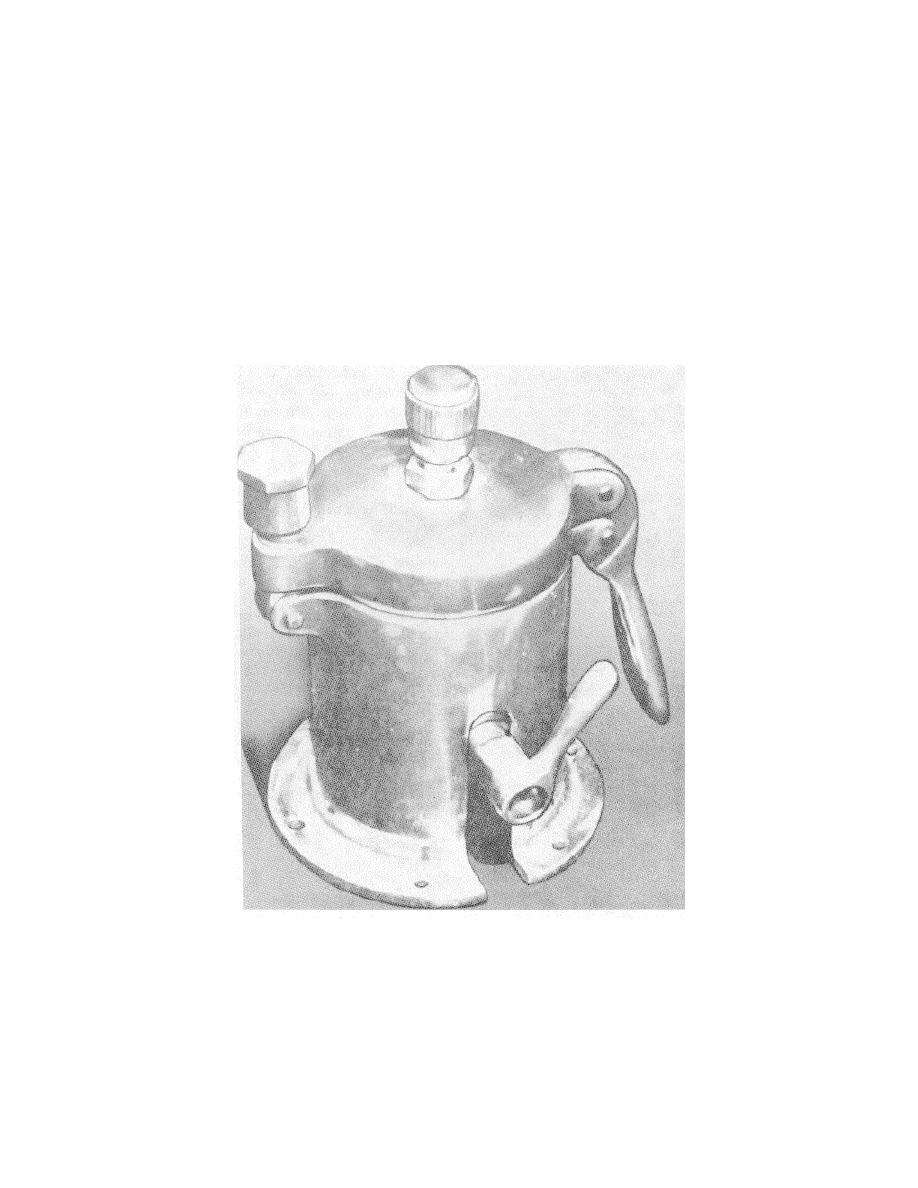

Figure 2-33. Dry Ice Machine

2-61