purged of polyglycol brake fluid in accordance with the

5. Safety. Normal safety precautions must be observed

following procedure:

when handling polyglycol and silicone brake fluids to

prevent eye contact or ingestion. Do not allow brake

(1) Remove gage and empty contents per para-

fluid to contaminate ground water. Spills must be

graph 6c.

soaked up with absorbent material and collected for

(2) Pour 1 pint minimum BFS into filler bleeder.

disposal.

(3) Reinstall gage, invert filler bleeder, shake

6. Requirements.

vigorously.

(4) Return filler bleeder to normal position and

a. The conversion procedures must be followed as

pressurize to 30 P.S.I., bleed at the gage and discharge

they appear in this bulletin and/or with the bleeding pro-

as much fluid as possible from the end of the hose

c e d u r e s o u t l i n e d i n t h e a p p l i c a b l e vehicle/equipment T M .

(Reference paragraph 6c).

It is important to remove as much polyglycol as possible

(5) Release pressure in the filler bleeder, remove

in order to obtain the benefits of BFS.

the gage, invert the unit to drain any remaining residual

b. The chart below outlines specific requirements

fluid out (Reference paragraph 6c).

when converting certain vehicles to BFS.

(6) Brake fluid, silicone is a bluish/purple color

and polyglycol brake fluid is a light amber color. Test

CAUTION

results have shown that some procurements of BFS will

change color under certain conditions (storage in hot

Brake shoes of any vehicle contaminated

environments (i.e., +140F or direct sunlight) for ex-

with BFS must be replaced.

tended periods of time). If a BFS container has been

previously opened (indicated by a broken seal) and the

NOTE

contents are not bluish/purple in color, discard the con-

Check master cylinder area for decal or tag

tents. A color other than bluish/purple is acceptable for

to see if vehicle was previously converted to

new containers of BFS with the seal intact.

BFS. If not, convert to BFS.

7. Pressure Bleeding Flush/Fill Method (preferred

method).

c. Purged fluids wiIl be drained into a suitable con-

CAUTION

tainer and disposed of in accordance with procedures

Do not use solvents of any type to flush

established by the local environmental control officer.

brake system.

d. The hydraulic pressure filler bleeder must be

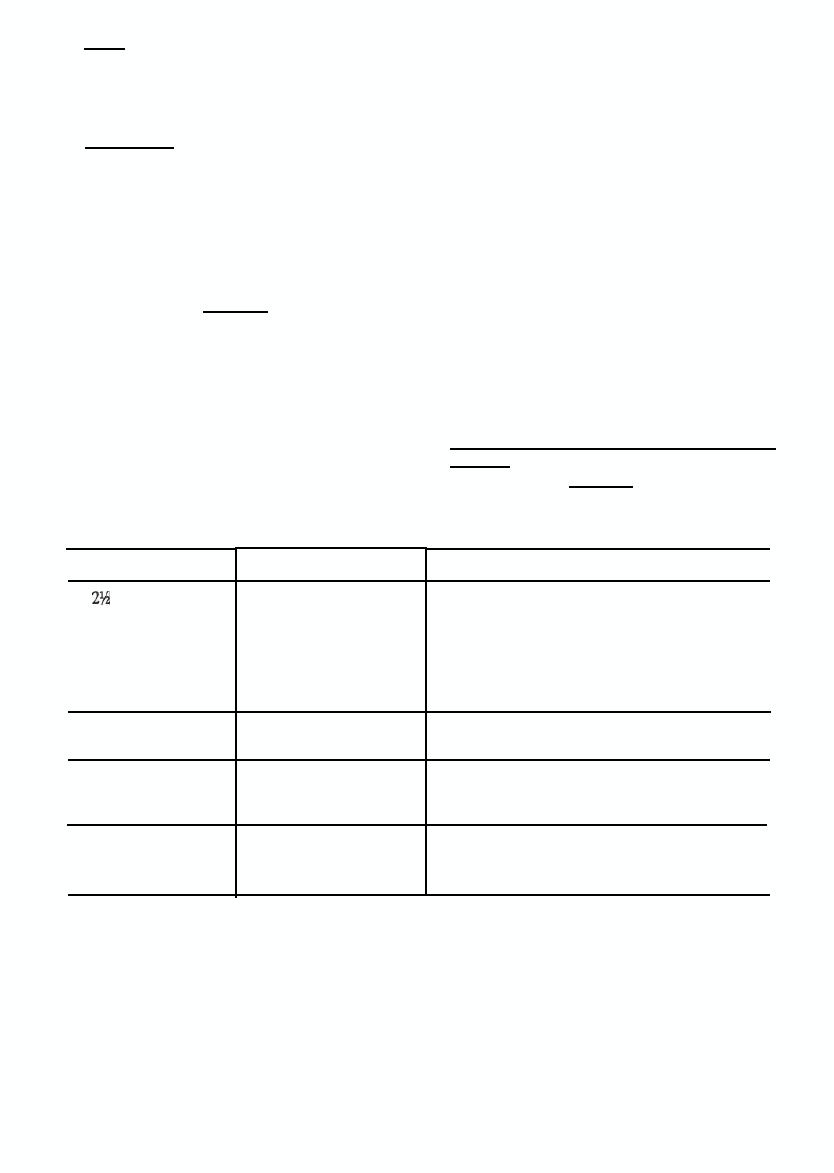

Models/Series of Vehicle

Item

Required Action

Air/Hydraulic Unit

All

Ton Tactical Trks

1. Bleed vehicle air system prior to BFS conversion.

(M44 S e r i e s )

2. After conversion, start engine and let air pressure

return to normal. Pump brake pedal several times.

If master cylinder reservoir level goes down and no

external leaks can be found anywhere on the vehicle,

replace air/hydraulic unit.

M809, M39 Series 5 Ton

Vehicle Air Supply System

Bleed system before BFS conversion.

Tactical Trks

M561 1 - 1 / 4 T o n G A M A

Brake Drum/Shoes

If any BFS leaks from bleeder screw into brake drum,

Goat

replace brake shoes and remove all BFS from inside

drum.

All Army Vehicles

During flush and fill procedure, fluid leaking from

Master Cylinder Boot

master cylinder boot is acceptable providing fluid

leak stops when filler bleeder is disconnected.