TM 5-3655-210-12

(5) Remove the nozzle assembly (11) and

adapter (7) from the holder.

(6) Remove the electrode (6) and lock

washer (4) from the head.

(7) Remove the three screws (16) and washer

(15) securing the chamber (1) and gasket (2) to the

head. Remove the gasket and chamber.

WARNING

Dry cleaning solvent, P-D-680 or P-S-

661, used to clean parts is potentially

dangerous to personnel and property.

Use in a well-ventilated area as the

fumes are dangerous if inhaled. Avoid

repeated and prolonged skin contact.

Do not use near open flame or

excessive heat. Flash point of solvent

is 100F.-138F. (38C.-59C.).

c. Cleaning, Inspection and Repair. Clean all parts

in a cleaning solvent. Inspect the spark plug and

electrodes. Inspect the plug for cracked or broken

porcelain. Replace the plug if damaged. Inspect for

worn electrodes. Replace ground electrode if worn.

Inspect the spray nozzle for cracks, burrs, broken

screen, or any other damage and replace if damaged.

Inspect for damaged threads and gaskets. Replace all

damaged hardware and gaskets.

NOTE

When the spark plug and the ground electrode are

installed, the gap between the two should be 3/16

(0.188) to 1/8 (0.125) inch (.4775 -.3175 cm).

d. Reassembly.

Reverse the disassembly

procedures in b. above to reassemble the combustion

head.

e. Installation. Reverse the removal procedures in

a. to install the combustion head.

f. Spark and Plug Gap Testing

(1) Disconnect the solenoid wire by removing

the machine screw (20, fig. 4-106) and lifting the wire

out of position to shut off the fuel supply.

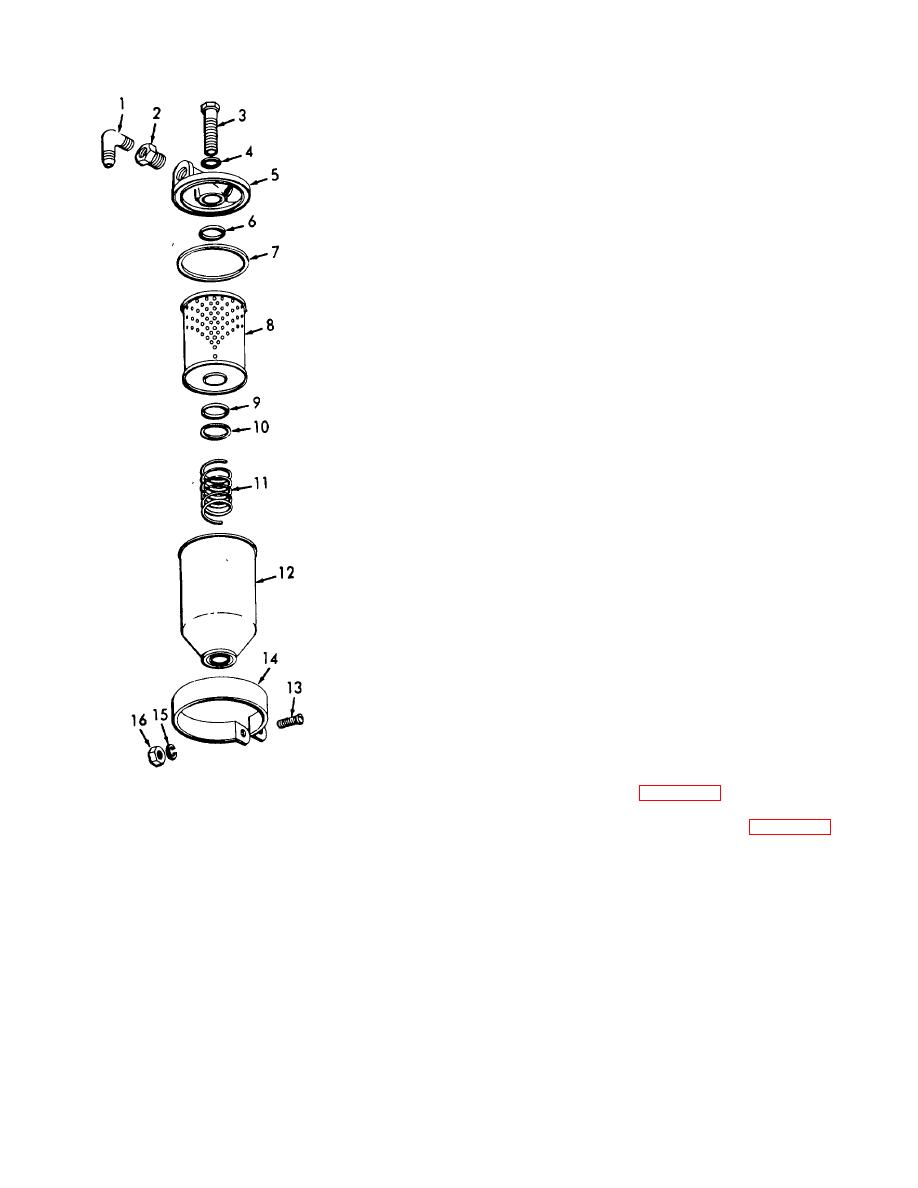

1.

Adapter elbow

9. Washer

(2) Remove the fuel tube (17, fig. 4-108).

2.

Bushing

10.

Flat washer

(3) Remove the head assembly with plug wire

3.

Machine bolt 11.

Spring

installed.

4.

Washer

12.

Body

(4) Start the unit and check the spark for

5.

Filter head 13.

Machine screw

intensity (it should be a vivid blue in color). Check the

6.

Gasket

14.

Clamp

spark plug gap (3/16 (0.188) to 1/8 (0.126) inch (.4775-

7.

Gasket

15.

Lock washer

.3175 cm).

8.

Element

16.

Nut

(5) Secure the combustion head to the

heater.

Figure 4-109. Fuel filter, exploded view.

(6) Install the fuel tube and solenoid lead.

g. Spray Nozzle Test. Remove the nozzle holder

(3) Remove the nut from the bail.

from the head and with the fuel pump working check the

(4) Lift the nozzle holder (10) and packing

angle of fuel spray. It should be 600 to 1200 with a

(12) from the head.

uniform cone. If the spray angle is not

4-123