TM 5-6640-212-14

b. Operation.

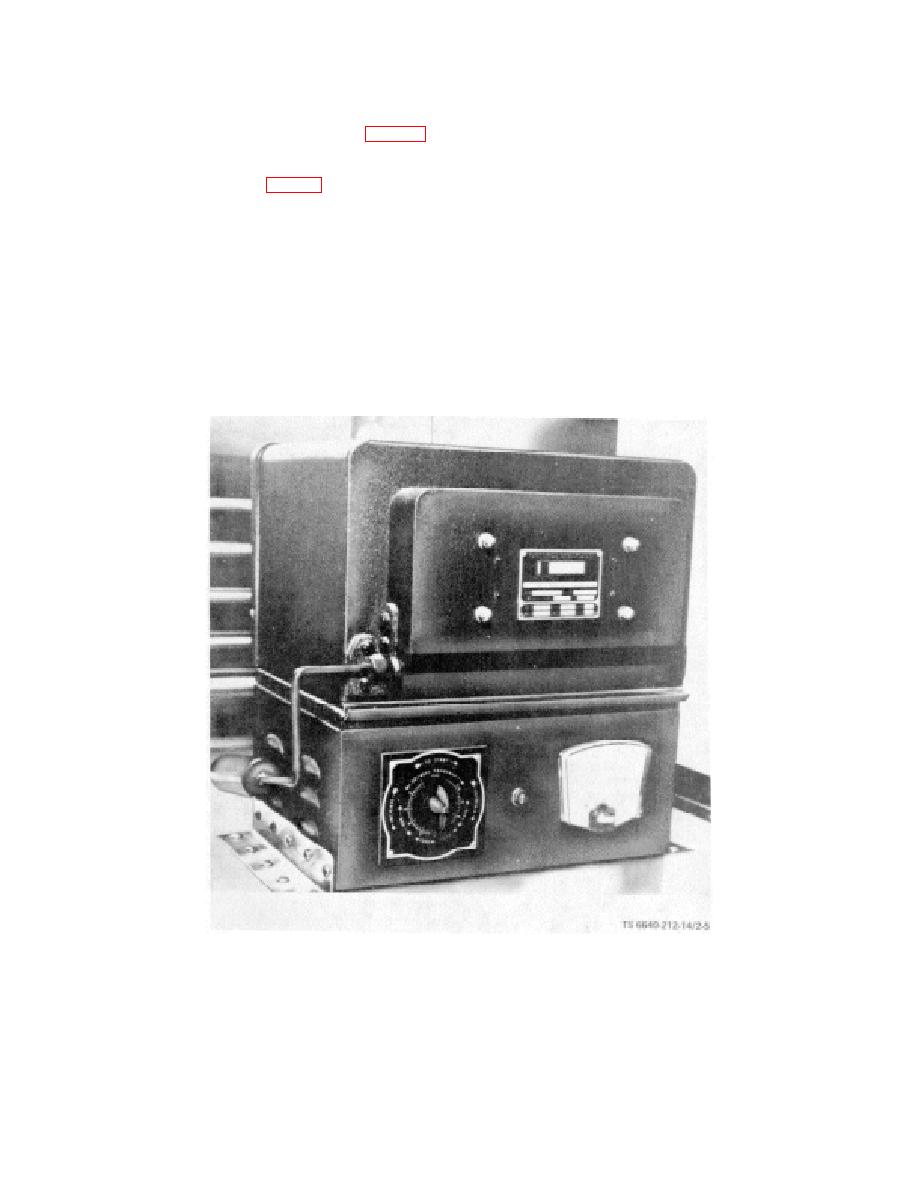

2-12. Muffle Furnace.

(1) Place the toggle switch in the ON position.

a. Description. The muffle furnace (fig. 2-5),

The pilot light is illuminated while heat is on.

designed to comply with the requirements specified in

(2) Set the percentage timer. The timer operates so

ASTM D482, D874, and D2276 (TM 10-1166), is located

that heat is on for a set percentage of 1 minute and off

on the left-hand work counter (fig. 1-2). The furnace is

the remaining part. For example, with the timer set at

used for heat treating, precipitate drying, ashing, igniting,

20, the heat is on 20 percent of 1 minute and off 80

and fusing. It has a continuous operating temperature

percent; a setting at 60 controls temperature at

range from 150 degrees F to 1800 degrees F (66

approximately 1800 degrees F (982 degrees C).

degrees C to 982 degrees C). Intermittent heating as

high as 2000 degrees F (1093 degrees C) will not

(3) For quick heat-up, set the timer at 100 which

damage the muffle winding or refractories. The furnace

provides continuous heating, but make sure to turn back

consists essentially of a muffle chamber with drop door

the timer when pyrometer shows temperature reading at

and steel tray, and a base which houses a temperature

1800 degrees F (982 degrees C) to prevent burning out

gage (pyrometer) showing both Fahrenheit and

of heaters, refractories, etc., caused by excessive

Centrigrade scales, percentage timer, pilot light, and ON-

temperatures.

OFF toggle switch.

Figure 2-5. Muffle Furnace.

2-11