TM 5-6640-212-14

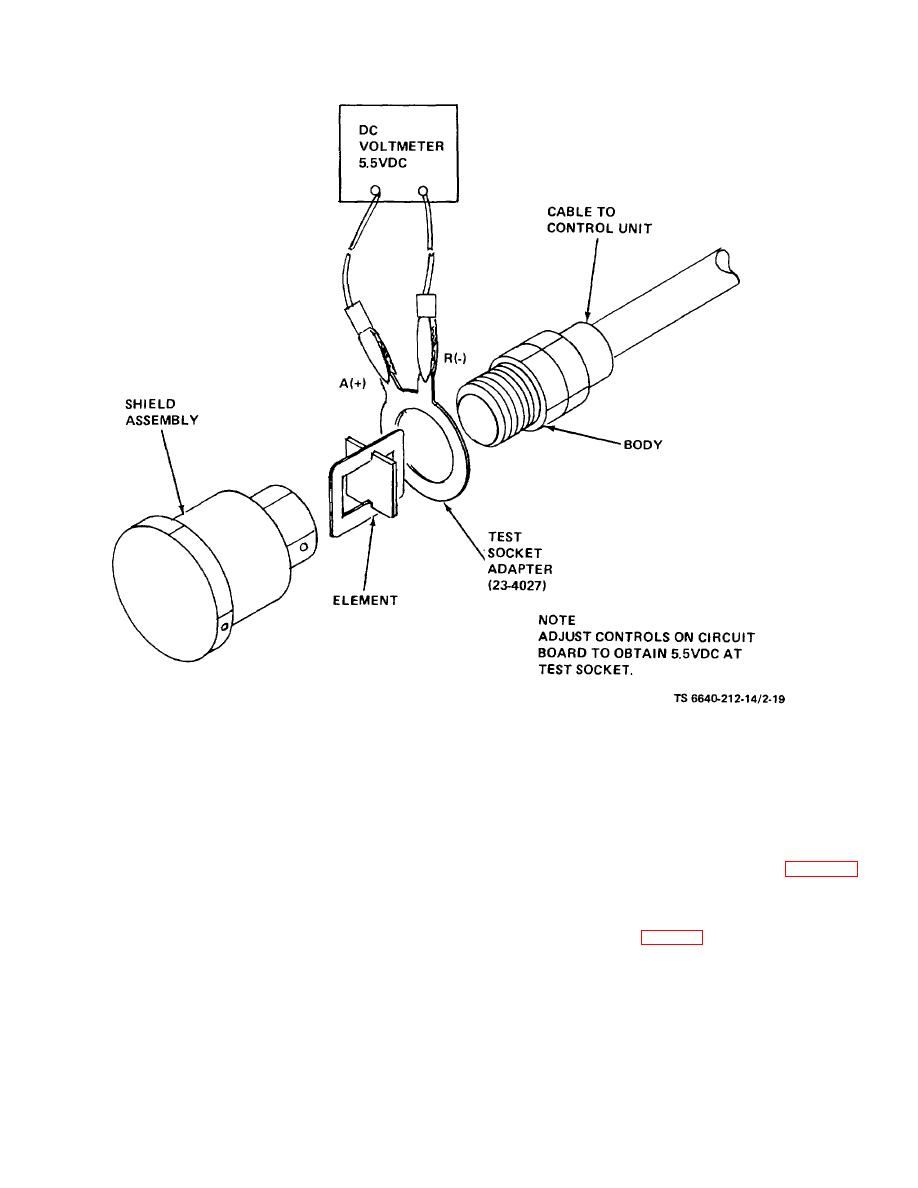

Figure 2-19. Test Setup, Element 5.5 VDC Check

(2) Detector voltage being set abnormally low.(3)

(4) If voltage is still incorrect after element

replacement, replace the printed circuit board (B, fig. 2-

(3) Excessive negative meter drift.

18).

g. Power Supply. The power supply is designed to

b. Troubleshooting Refer to table 2-2 for

maintain a constant voltage to the detector circuits

troubleshooting procedures.

despite variations in the input voltage. If the voltage at

2-23. Analytical Balance.

test points B on the printed circuit board is incorrect and

a. Description. The analytical balance (fig. 2-20),

cannot be brought to the correct value by adjusting the

voltage adjuster, proceed as follows:

designed to meet the requirements specified in ASTM

(1) Make sure that the module is fully inserted into

Method D2276 (TM 10-1166), is located on the right-

its socket.

hand counter adjacent to the entrance door, above

drawers K1 and K2 (fig. 1-2). It has an automatic

(2) Check fuse (or circuit breaker). Light will be off

preweighing and single-knob taring system.

It

on all modules if fuse is burned out (or circuit breaker

incorporates full 1000-milligram optical range with digital

has tripped).

readout. The numbers to be read on the optical scale

(3) Check

the

detector,

and

replace

if

appear in a clear window while all neighboring values are

necessary.

visible, but subdued, through a green filter.

2-36