TM 5-6640-212-14

NOTE

If a tared weighing boat is used,

remove the tare ring and zero with

the empty boat on the pan.

(11) To weigh to a preset weight, adjust the weight

control knobs and, if necessary, the micrometer drum

knob to the desired value. Preweigh, following steps (9)

(a) through (c), move the arresting lever to the full

release position, and adjust the volume by use of filter

paper or a glass rod until the value is reached.

(12) The weighing results can be corrected for

conditions requiring absolute weighings. The switching

weights are made on noncorrosive nonmagnetic steel

having a density of 7.88 grams per milliliter. For a

medium air density of 0.0012 grams per milliliter, they

are adjusted to match brass weights of density 8.4 grams

per milliliter.

Differential weighing of the same material do not require

correction. In case of absolute weighings, the result of

the following formula has to be added to the weighing

result.

COKn (1.10-5 (PL/PG) + (PL/PP) grams where

n

= reading of the balance in grams

PL = the density of the air in grams per milliliter

PG = the density of the switching weights in

grams/milliliter

PP

=the density of the weighing material in

grams/milliliter

2-24. Distillation Test Apparatus.

a. Description. Two distillation units (fig. 2-23) are

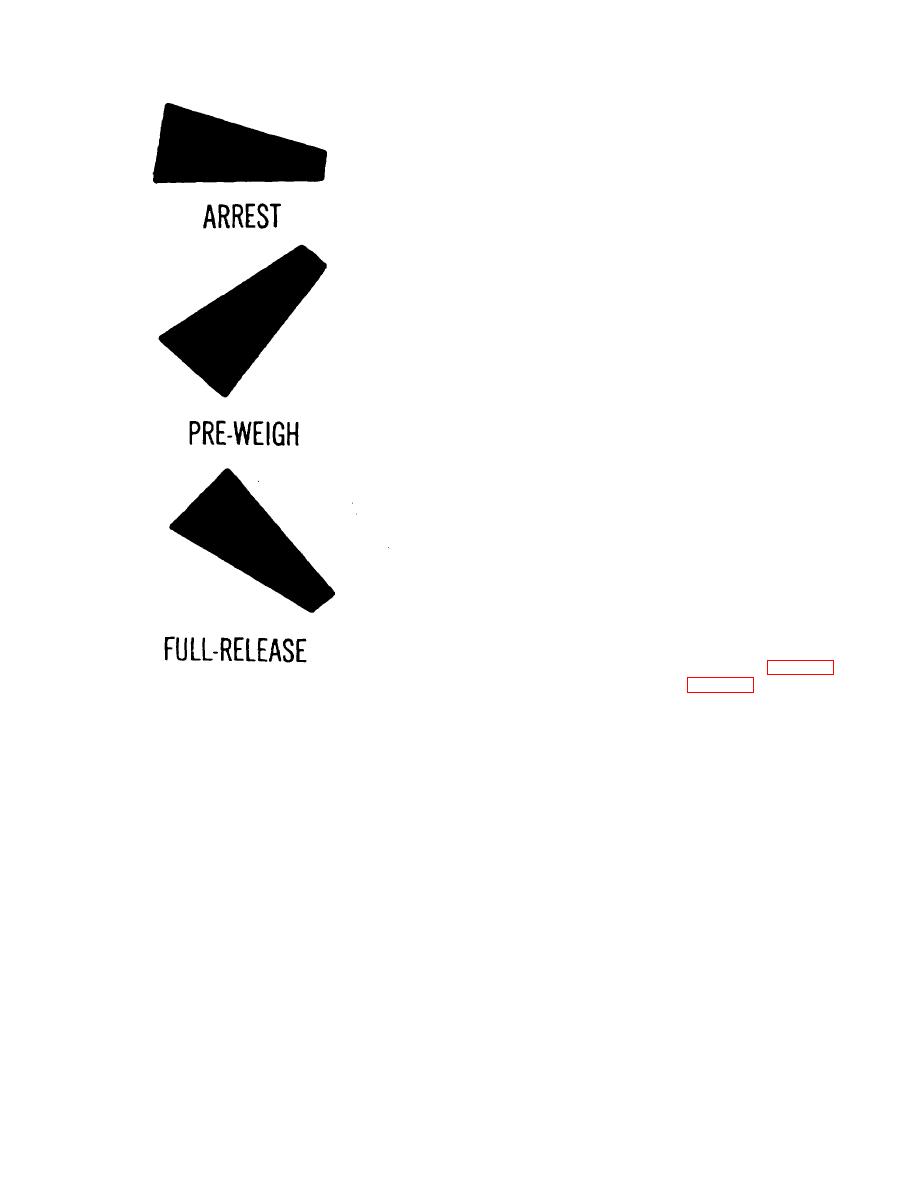

Figure 2-22. Arrestment Lever Positions

located above drawer L1 (fig. 1-2). Each unit is

designed to comply with the requirements specified in

(c) After obtaining a volume of 0.1 gram, remove

ASTM Method D86 (TM 10-1166) in the distillation of

the container from the double beam balance and place it

petroleum products. The righthand unit incorporates a

on the pan of the analytical balance. (Tongs should be

500-watt immersion heater for gas oils. Each unit

used).

consists of a shield assembly and a condenser

assembly. The shield and condenser exteriors are

(d) Adjust the volume by use of filter paper or a

constructed of stainless steel; the condenser interior of

glass rod.

copper insulated with a 1-inch thickness of fiberglass.

The ice-refrigerated condenser is equipped with a drain

(10) To tare containers over 1 gram, weigh the

and overflow outlet, and distilled oil outlet. The shield

container as noted above for any unknown weight.

incloses a 750-watt heater with autotransformer, two

After taring, if it is desired to fill the container with a

porcelain refractory blocks, observation window, an

specific volume, adjust the zero control knob to reflect

elevating device to allow proper alinement of distillation

zero on the optical scale, leaving the macro scale

flask to condenser tube, a temperature control assembly,

untouched. Proceed as in (9) (a) through (c) above, and,

and an ONOFF toggle switch. Wood blocks are stored

by use of filter paper or a glass rod, adjust to the specific

in drawer K1 (fig. B-16) for supporting cooling jar and

volume desired by accounting for the macro weight

graduate. Asbestos boards and covers are stored in

figure only.

drawer K1.

2-41