TM 5-6640-212-14

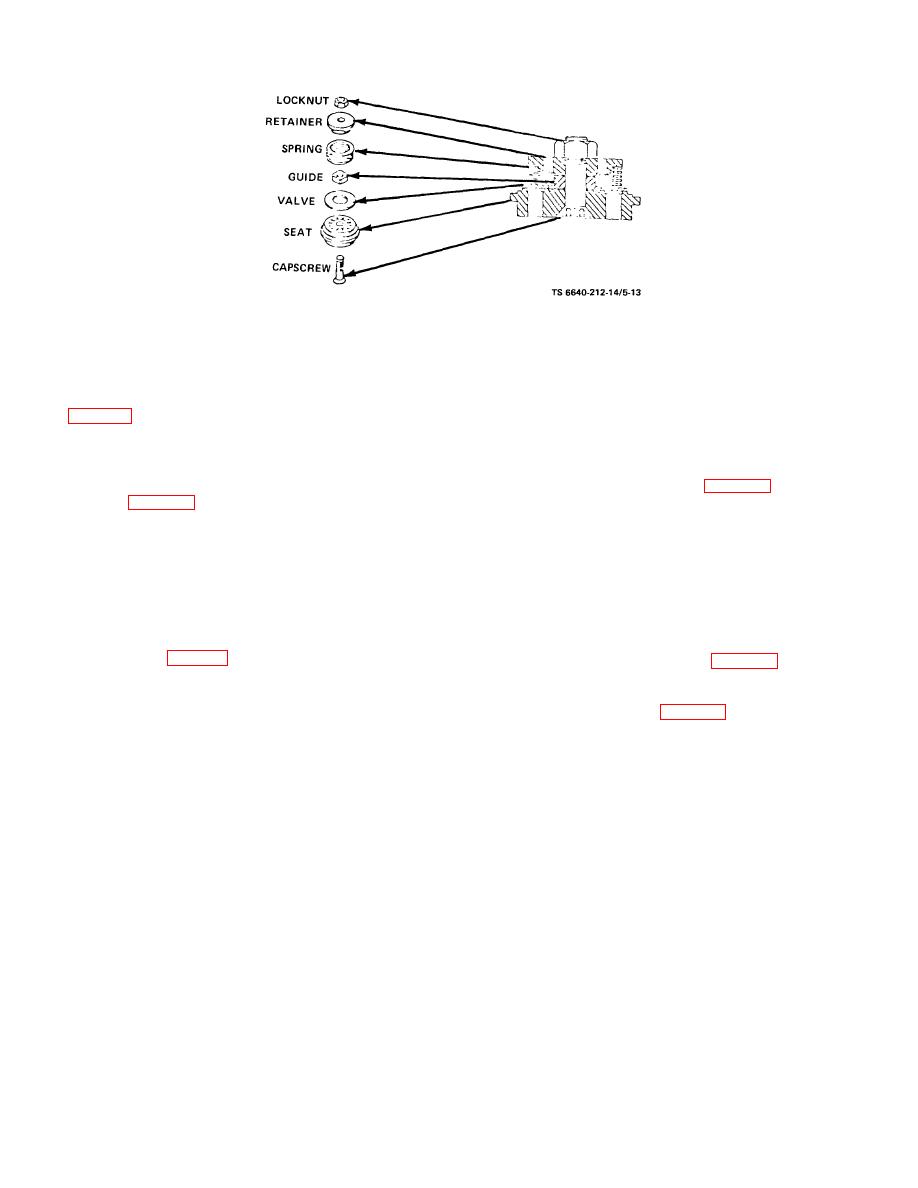

Figure 5-13. Discharge Valve, Cross Sectional and Exploded View

(4) Reassembly.

(3) Cleaning and Inspection.

Refer to figure 5-13 and

reassemble the discharge valve. Torque nut as specified

(a) Clean all parts thoroughly.

in table 5-4.

(b) Inspect for damage and wear.

(5) Installation.

(c) Replace damaged or worn parts.

(a) Place the discharge valve gasket and

(4) Reassembly.

discharge valve in the cylinder head.

(a) Refer to figure 5-15 and reassemble suction

(b) Install discharge valve plug. Torque as

valve. Torque nut as specified in table 5-4.

specified in table 5-4.

(b) Refer to figure 5-14 and reassemble the

(c) Install the cap gasket and discharge

unloader.

valve cap.

NOTE

e. Suction Valve Unloader. Suction valve unloader

Before installing the unloader apply a

should be removed, cleaned, and inspected after

light coat of silicone grease (MIL-L-

approximately six months of operation and the unloader

4343A or equivalent) to the outside of

repacked with grease.

the plunger and to the inside of the

(1) Removal.

hold down sleeve and seals.

(a) Disconnect the unloader tubing from the

(5) Installation.

suction valve cap (fig. 5-14) and remove the cap and O-

(a) Install the gasket (18, fig. 5-16) and suction

ring.

valve in the cylinder head.

(b) Remove the unloader assembly from the

(b) Place the unloader over the suction valve

cylinder head and lift out the suction valve and gasket.

and tighten as specified in table 5-4.

(2) Disassembly.

(c) Install the suction valve cap and attach

(a) Refer to figure 5-14 and disassemble the

the unloader tubing.

unloader.

f. Cylinder Head. Remove cylinder head only if

(b) Refer to figure 5-15 and disassemble the

loss of compressor pressure has been isolated to a

suction valve

defective cylinder, or severe knocking points to in-

ternal problems within the cylinder.

5-24