TM 9-4910-743-14&P

Preparation for Use and Installation Instructions.

1.

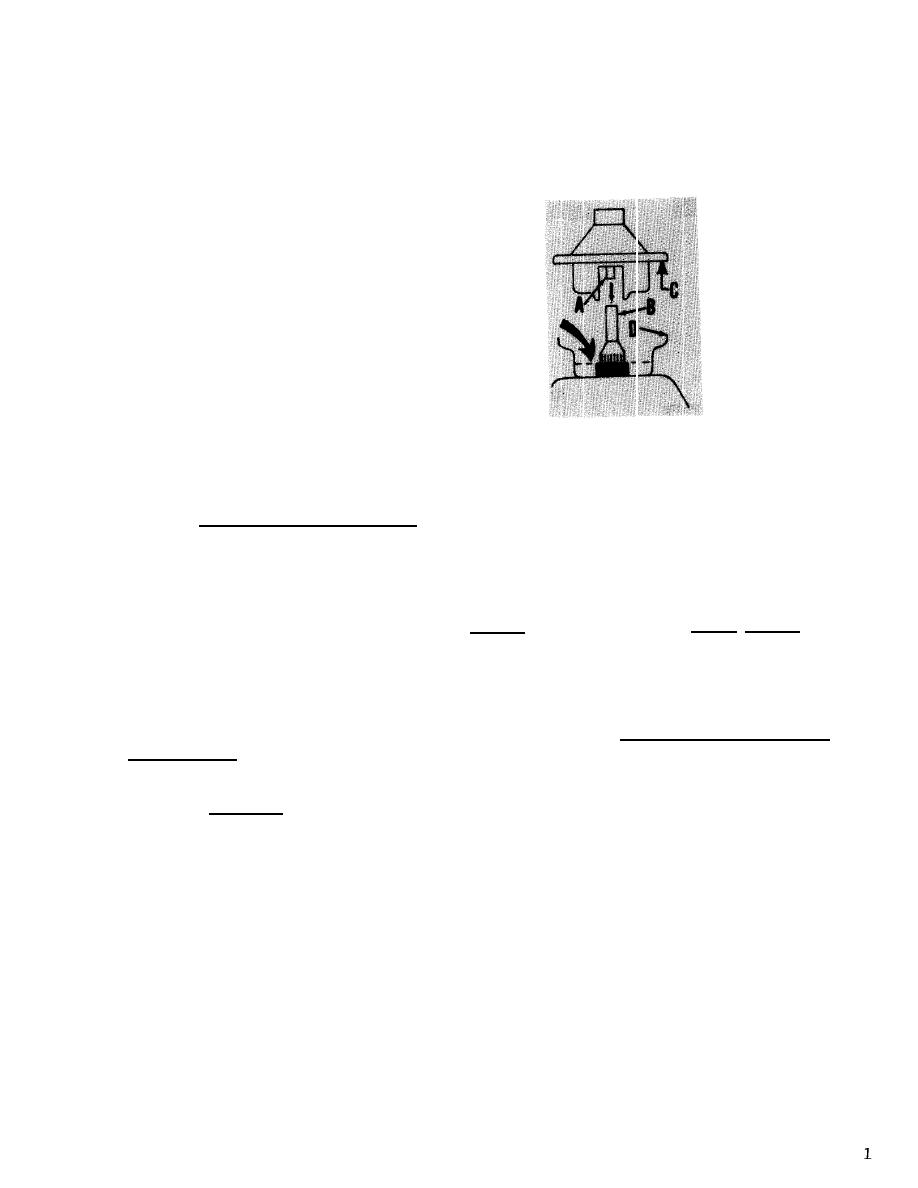

a. DAMPENING OIL: Remove

the chrome balancer head out

of the dampener basin and fill

the basin to the top of the

step on the center post with

SAE 20 (MIL-L-2104) motor oil,

approx. 6 fluid ounces.

Replace the head . . . be sure

that pivot post A fits into

tube B and flange C rests on

rim of dampener basin D. This

oil has no lubricating value.

It will not wear out nor will

it need to be changed. The

oil is an oscillation dampener

to stabilize the balancer

without interfering with

specified sensitivity or ac-

curacy.

b. Required Setup Procedure:

To be performed at time of installation and

whenever Balancer is moved.

(1) Place a tire and wheel assembly on the Balancer (make sure that the

foot pedal is in the "OFF" position).

(2) Using the leveling legs, CENTER the bubble on the CROSS HAIRS.

(3) Turn the Balancer on, using the foot pedal.

(4) Balance the tire and wheel assembly.

(5) Rotate the tire and wheel assembly turn WITHOUT LIFTING IT FROM

THE BALANCER (to ensure that the Head remains engaged).

(6) IF the bubble has moved from dead center, use the leveling legs to

bring it HALF-WAY back from dead center.

The unit is now ready for use.

2.

General Theory of Operation.

a.

Static and dynamic unbalance result from an uneven distribution of

weight.

To correct static and dynamic unbalance you must first locate the heavy

area, then counterbalance.

This resolves itself to a simple weighing procedure.

The degree of accuracy to which you can balance depends entirely upon the ac-

This is pre-

curacy of the weighing device, in this case, the wheel balancer.

cisely what your wheel balancer is -- a sensitive and accurate weighing device.

Its operation meets the following specifications: