TM

9-4910-743-14&P

(b) Be sure wheel seats flat

on flange to assure accurate reading.

(c) Place pedal to "ON" position.

(d) Hang weight on rim (not on

tire) . Lay one of the remaining 2 weights at

each mark and check for balance. Adjust to

center the bubble by moving weights closer

together or farther apart. EASY, now only

small movement is needed.

Place pedal to "OFF" position.

(e)

(f) Attach outside weights while wheel is still on the balancer.

4.

Maintenance Instructions.

a.

Daily cleaning.

It is necessary to periodically clean the wheel

balancer to maintain accuracy. Daily, wipe the chrome head with a rag damp with

kerosene (9140-00-242-6749). DO NOT POUR KEROSENE ON THE BALANCER. Any liquid

trapped in the cup under the cone will impair the machine's ability to balance

and cause the cone to stick.

Wipe the cabinet clean, using a rag damp with

kerosene, as required.

b. Major Cleaning. Major cleaning is required only occasionally and is

indicated by the cone becoming tight on the center tube. When the cone becomes

tight it may stick down so the wheel cannot be centered. A sticky cone may not

go down easily and may hold a light wheel up.

CAUTION

The wheel balancer head is manufactured to very accurate and close

tolerances.

When cleaning be very careful not to drop it.

(1) DISASSEMBLY: To relieve a sticky

cone , remove the entire balancer head from the

oil basin and wipe clean with a rag.

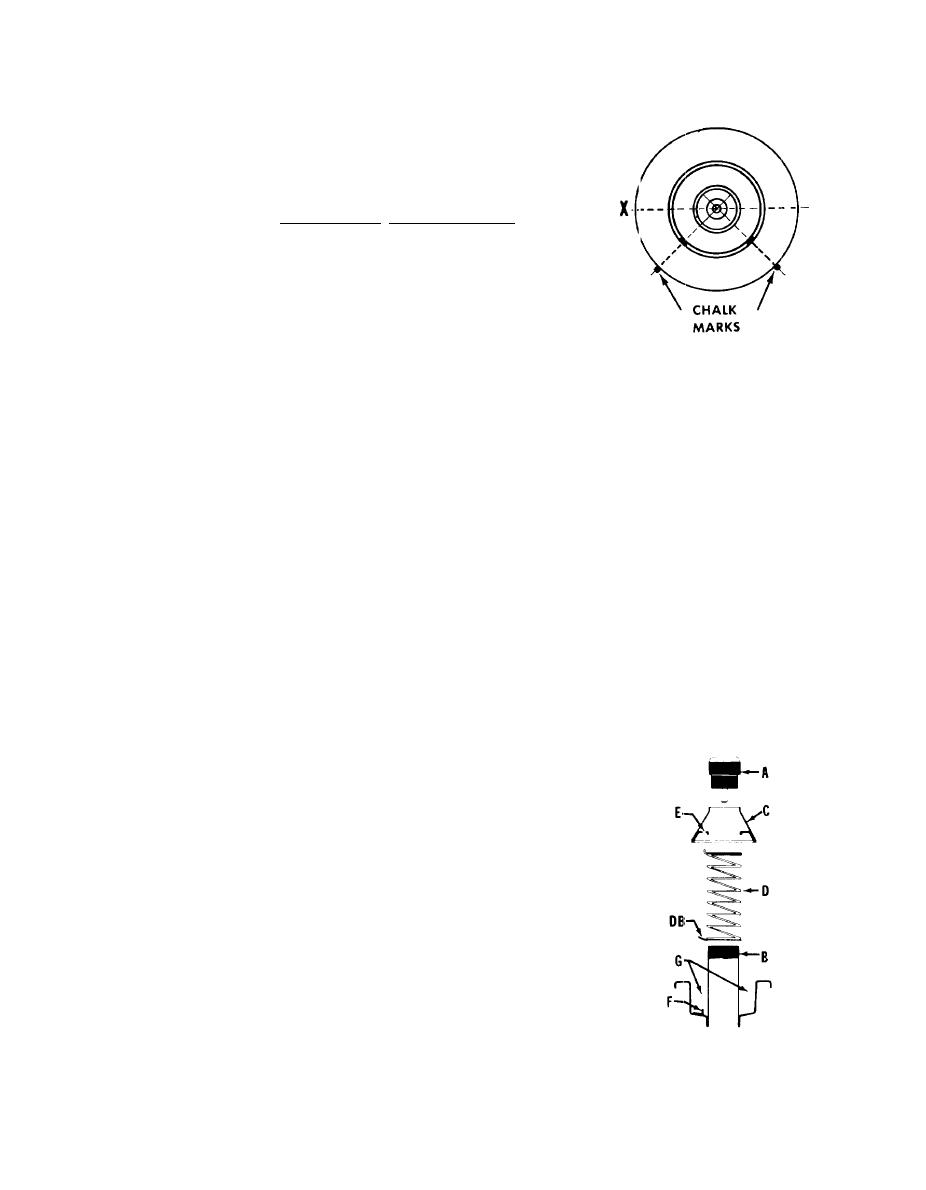

(a) Press the cone C down with one

hand and hold it depressed. Unscrew cap A and

remove from tube B.

(b) Release cone C which will pass

off over end of tube B and stand on extended

spring D.

(c) Lift spring D and cone C out of

basin G and then remove spring D from cone C.

6