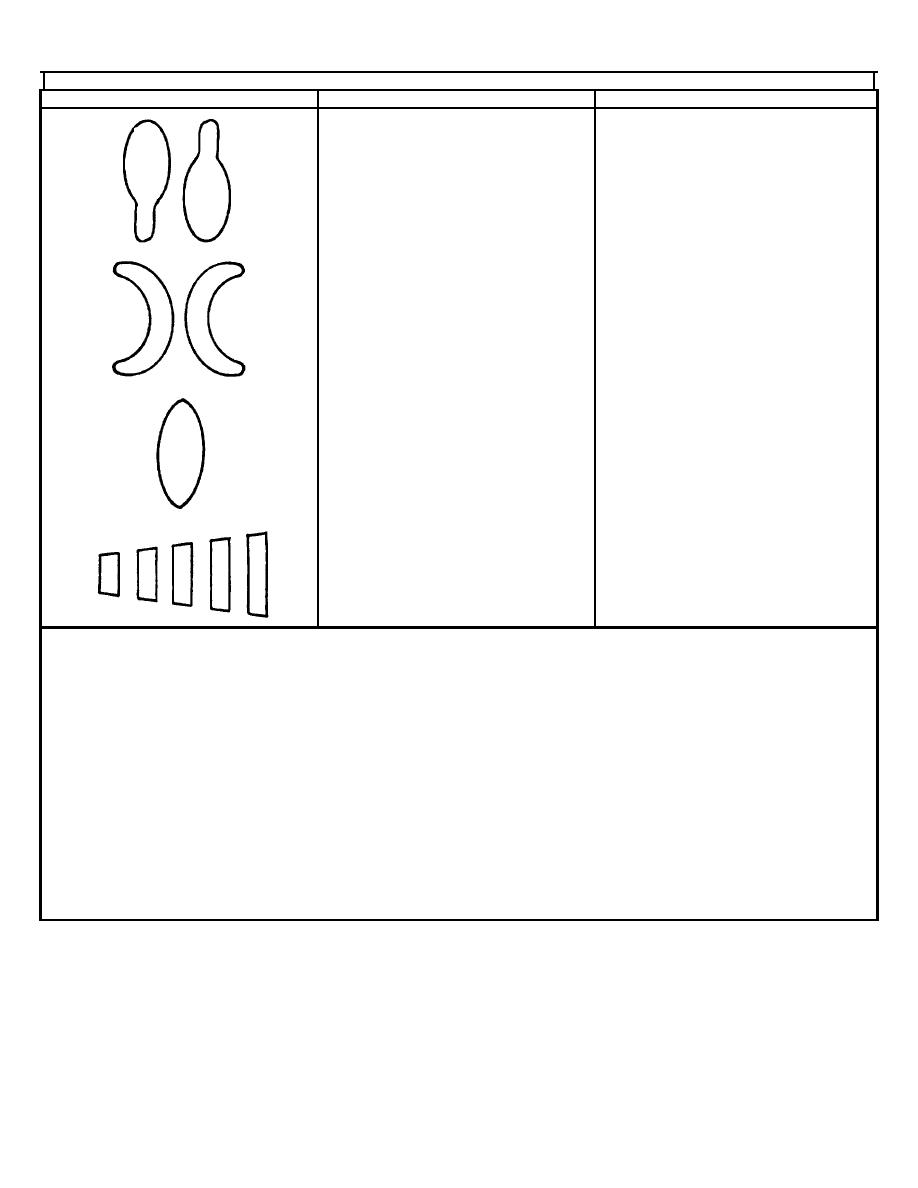

TROUBLESHOOTING AND REPAIR

PATTERN

TROUBLESHOCAUSE

CORRECTION

Dissolve material in side ports with

Dried Material in side port hole. re-

thinner.

stricts passage of air. Greater flow of

air from clean side port hole forces fan

Do not use metal instrument

pattern in direction of clogged side.

Remove air nozzle and clean off fluid

Dried material build-up on the outside

tip, using rag, wet with thinner. Tighten

of the fluid nozzle tip restricts the

air nozzle.

passage of atomizing air at one point

through the center opening of air noz-

zle. This pattern may be caused by

loose air nozzle.

Reducing air pressure will correct cause

A split spray or one that is heavy on

(1). To correct cause (2), open fluid

each end and weak in middle by (1) too

control needle, at the same time turn

high an atomization air pressure, or (2)

fan control in. This will reduce width of

by too wide a spray pattern with thin

spray but will correct split spray pattern.

material.

1. Fill Cup

1. Insufficient fluid in cup.

2. Clean

2. Obstructed fluid Passage or hose. 3.

3. Retighten or replace

Loose or defective cup

4. Retighten or replace

4. Loose fluid tip or defective

. Lubricate or replace. Tighten.

5. Dry or worn packing (301 or loose

packing nut 16).

MAINTENANCE & CLEANING

Lubrication - Place a drop of light machine oil on:

a. fluid needle packing.

b. air valve packing.

c. fan control packing.

d. trigger pivot point.

Coat the fluid control spring with petrolatum.

Cleaning - Empty material from cup and replace with compatible thinner or solvent. Replace cup and spray in the usual

manner to flush passage thoroughly and to clean tip of needle.

To clean air and fluid nozzles, soak them in solvent to dissolve any dried material and blow clean with air.

Never immerse gun in solvent beyond spray head.

2