TM

9-4940-500-14&P

SPRAY GUN

MODEL 76

DESCRIPTION

The Model 76 is a heavy-duty production spray

gun which will spray a complete range of materials,

such as lacquers to heavy synthetics, with ease, using

either a siphon cup or pressure feed.

OPERATION

There are two basic controls on the Model 76 spray gun.

The fan control (18) regulates air going to the holes

of the air cap. The fluid needle adjustment screw

(8) controls needle travel and fluid flow.

Mix and prepare material according to instructions

for siphon feed.

1. Attach air hose to gun at air inlet (10)

2. Attach cup or pressure feed to gun at material

inlet

3. Adjust air pressure to desired amount at the

Air Regulator

4. Adjust fluid volume by turning the fluid con-

trol screw (8) to the left or right.

5. Adjust to proper pattern by turning the fan

control screw (23) to left or right.

The most efficient atomization air pressure is the

lowest possible air pressure that will give the desired

results.

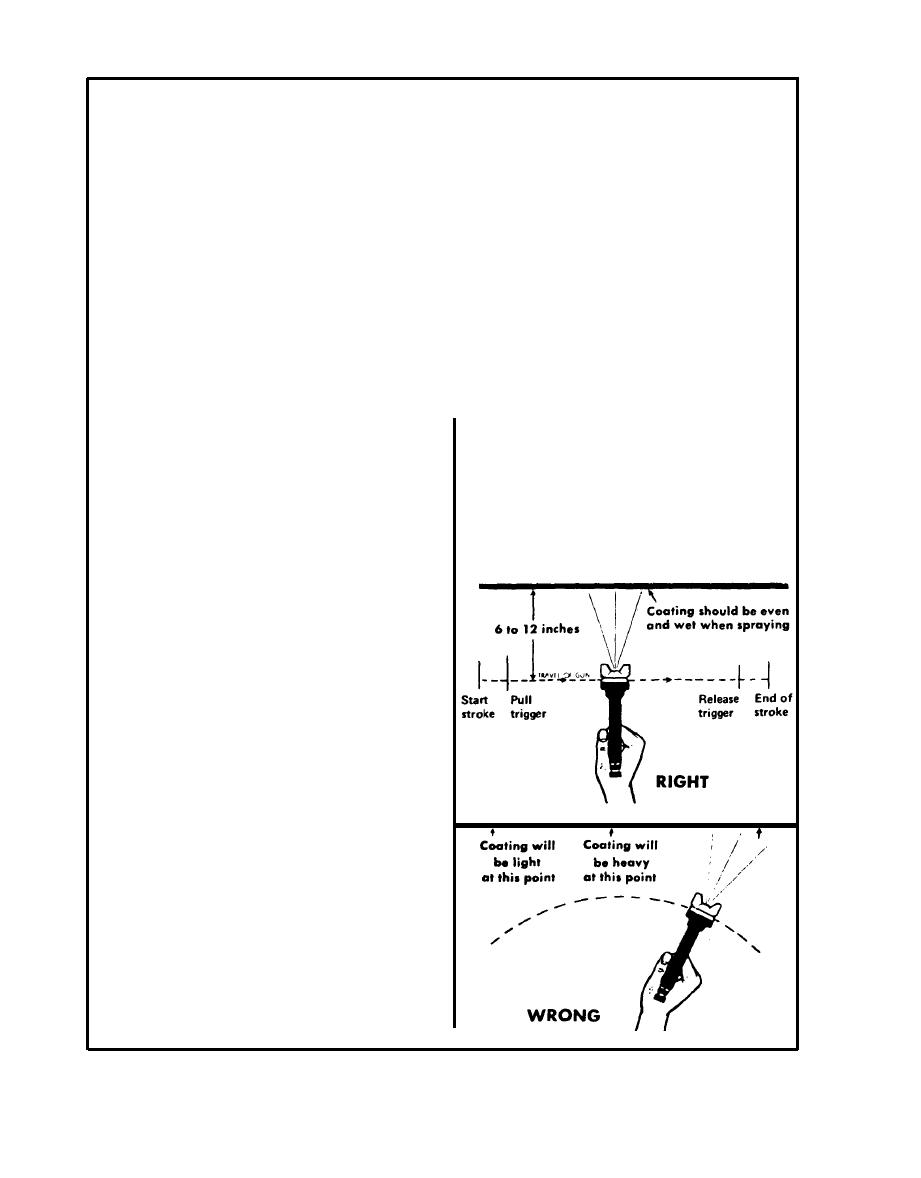

A spraying distance of 6 to 12 inches from gun to

work surface is recommended. The gun should be

held perpendicular to the surface being coated.

The stroke should be started before the trigger is

pulled and the trigger released before the end of

each stroke.

1