TB 43-0213

3-5.

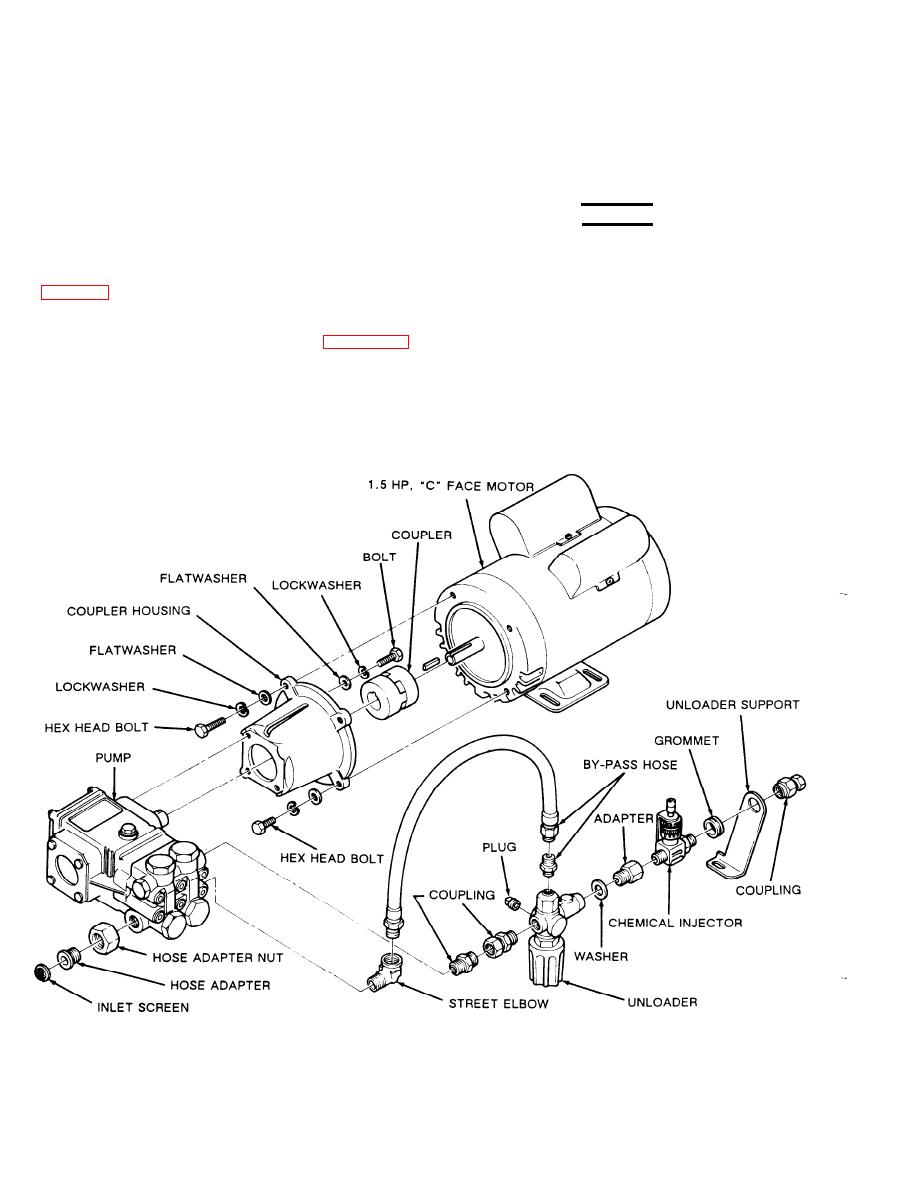

Material Pumps (Typical).

with the cylinder end immersed in the rustproofing

material. The air regulator and pressure gage most often

a. Pumps used in the application of rustproofing

attaches directly into the motor lead. The regulator

material are high pressure, air driven motors that mount

controls the air pressure going into the pump, thereby

directly onto the rustproofing material drum, A

also controlling the pump speed.

complete unit consists of the air motor or pump itself as

well as attaching air regulator, pressure gage, in-line air

filters, a bleed-type master air valve, material filter, and

WARNING

grounding log.

All material pump air lines must be purged

b, Commercial literature is available upon request

of air pressure after operation. Failure to do

from each of the supplies of material pumps listed in

so could cause the pump to cycle unexpect-

edly. Serious material injection injury could

when determining which pump best suits their

result.

operation. This literature also provides specific

maintenance and repair instructions. Figure 3-7

illustrates a typical material pump, This figure is

d. To ensure the safe operation of the pump, an air

representative only and is not intended to endorse one

bleed valve must be installed to purge the system of

product or supplier over another.

pressurized air after operation. This bleed valve may be

c. The air motor pump consists of the air motor and

built into the air regulator and gage, or may be a

piston cylinder. The assembly rests on a drum topped

separate item, depending on the supplier.

TA504756

Figure 3-4. Pump Motor Assembly (Typical).

3-6