TB 43-0213

also using the sand injector kit for wet sandblasting of

WARNING

large corroded areas. In the application shown, the

water source is hooked up to the pump, The power

Silica exposure hazards exist whenever sand

source operates the pump motor. Water is drawn by the

particles are injected into the air, Wet

pump and pressurized out to the gun assembly and

sandblasting lessens health risks, but care

wand. The sand injector kit is a simple tube device. One

must be taken to ensure that applicators

end of the tube is inserted into a container of dry sand.

use the recommended protective equip-

The opposite end of the tube is connected to the end of

ment. Silica exposure due to failure to wear

the wand. Pressure from the water shooting out the

protective equipment can result in silicosis,

wand draws the sand up through the tube.

a lung disease similar to emphysema.

NOTE

Sand is used to clean away corrosion from

large areas of the vehicle. Sand itself is

highly abrasive and will quickly wear the

affected surface down to bare metal.

b. Sand injector kits for wet sandblasting of

corroded surfaces can also be adapted for use with

powerwash equipment. Wet sandblasting should never

be implemented indoors nor without use of protective

clothing, gloves, goggles, ear protection, and facial

respirators.

c. Commercial literature is available upon request

from each of the suppliers of powerwash equipment

listed in Table 3-2. This literature provides much valid

and useful information with regard to equipment

specifications, operation, and maintenance, CPC

officers responsible for establishing a rustproofing

program can use the commercial literature to determine

which type of equipment best suits the operation, and to

obtain maintenance information for the equipment of

TA504753

choice.

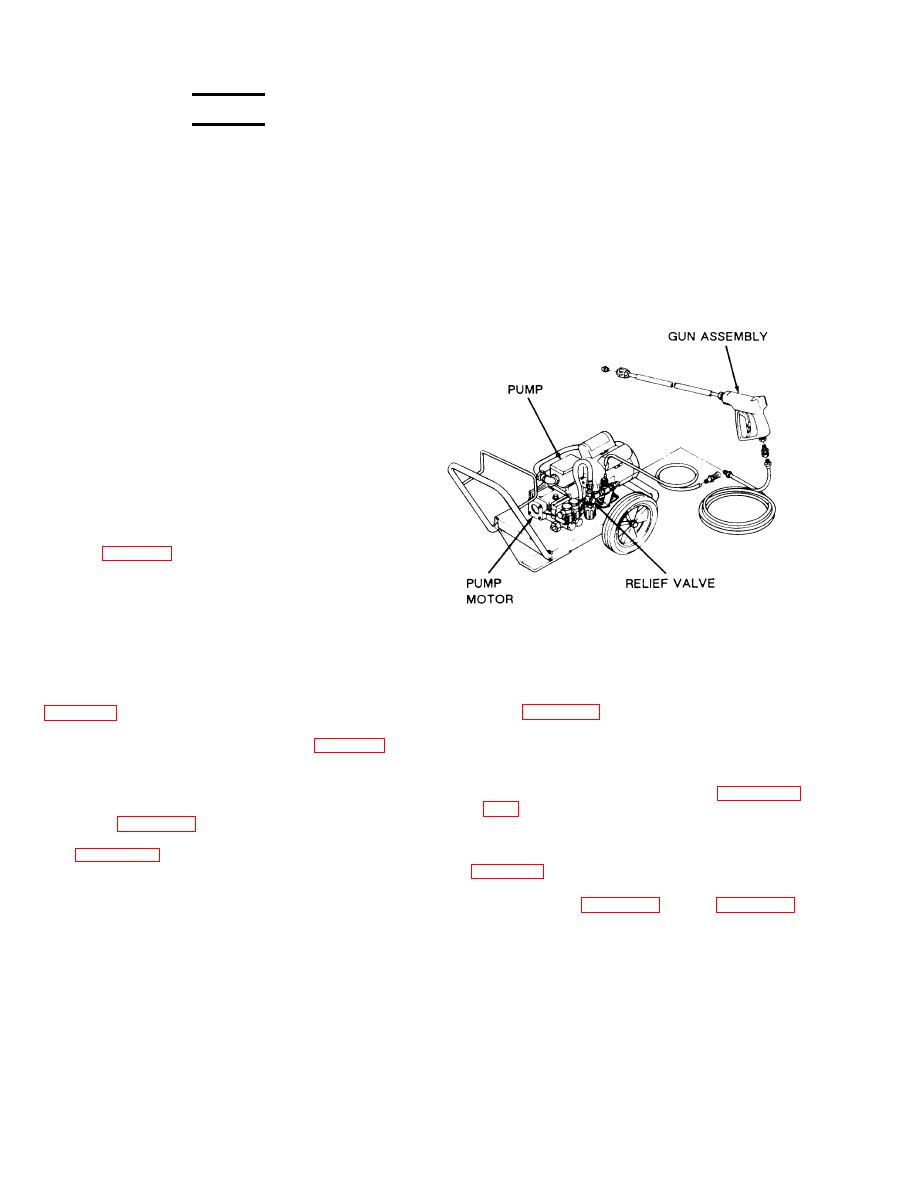

Figure 3-1. Standard Powerwash Equipment.

g. With the sand injector removed, the unit

d. All powerwash equipment suppliers listed in

illustrated in Figure 3-2 becomes a simple washer used

for cleaning the vehicle of dirt, oil, etc. The wand's

endorses one product or supplier over another. Sample

nozzle should be held a foot or so from the surface

troubleshooting instructions provided in Table 3-3 are

being cleaned and sprayed at an angle to the surface in

typical or representative of such equipment.

order to get underneath the grit. Stubborn deposits may

e. All powerwash equipment, regardless of size,

require the application of a detergent (see para-

power source, or portability, have common compo-

graphs 2-21 and 2-28). Detergents should be applied to

nents (see Figure 3-1).

an area from the bottom up and rinsed away from the

top down with the high pressure washer,

portable powerwash equipment operation with remote

for a typical powerwash unit. Nomenclature used in this

power (electrical) and water source. The applicant is

wearing the proper safety equipment and clothing and is

table is referenced to Figure 3-3 through Figure 3-6.

3-4