TB 43-0213

c. Clean material line filter every two weeks.

d. If slide valve freezes, use antifreeze through the

air intake to thaw out. Ensure that it is frozen and not

NOTE

simply stuck because of lack of lubrication.

If the grounding wire was disconnected

before servicing, be sure to reconnect

e. Never operate the pump at more that 100 psi

it before operating the pump.

(690 kPa). You will damage the piston within the pump

shaft.

f. If pump fails to operate, do not strike pump with

hammer, etc.

g. Never allow the pump to run dry. A dry pump will

quickly accelerate to a high speed, possibly damaging

itself.

h. Always flush the unit before material hardens in

any part of the system. How often flushing occurs

depends upon the material being used. Use the lowest

possible pressure to flush. Ground spray gun against

waste container.

i. After spraying, always turn off the air at its source

and purge the line using the air bleed valve. Disconnect

the air line coupler after the line has been cleared. At

the output end, trigger the gun into a waste container to

clear it of material under pressure. Engage the trigger

safety and disconnect the material line at the filter.

Clean gun and line.

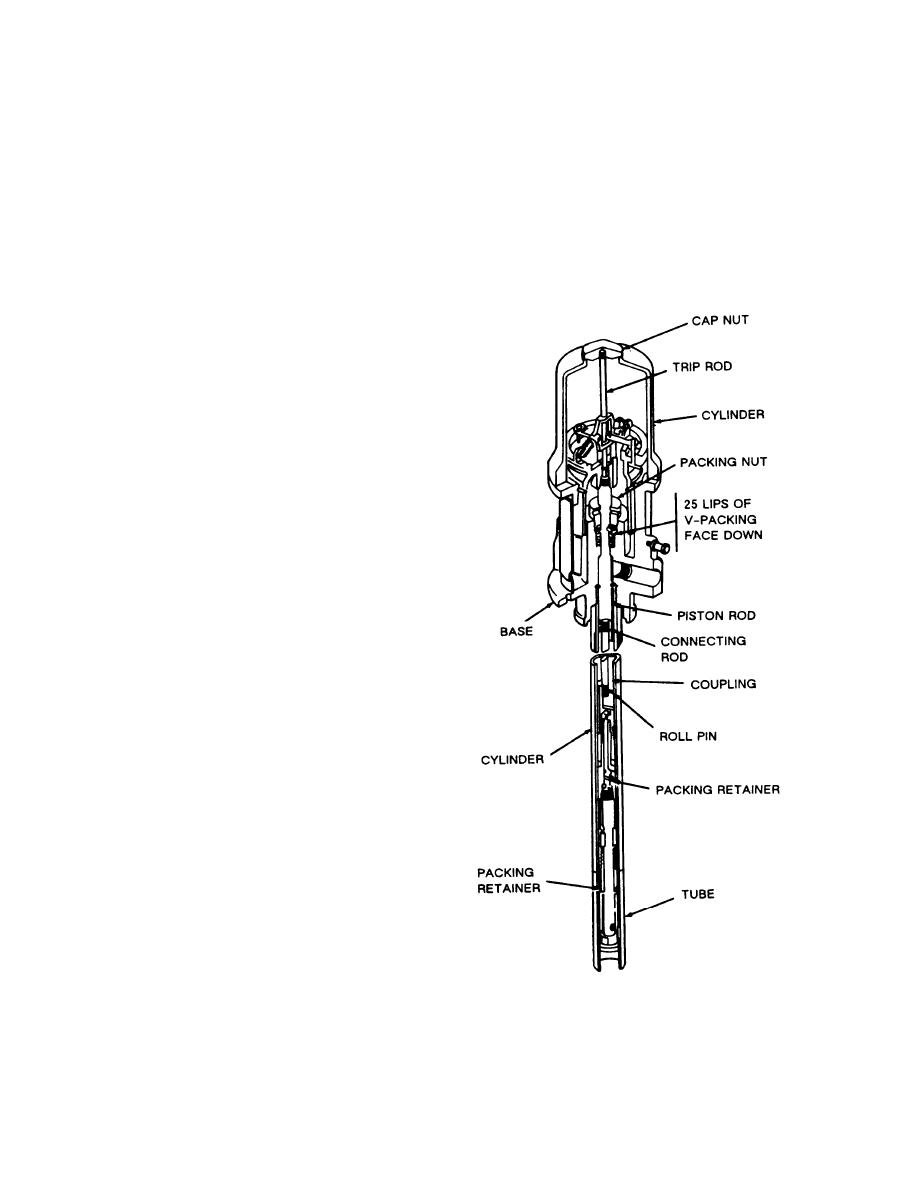

TA504760

Figure 3-8. Typical Pump

(Cutaway View).

3-10