TB 9-2350-368-25

FABRICATION

SECTION I. GENERAL INFORMATION

SCOPE. This chapter provides fabrication instructions for the M113A3/M113A2/M548A1&A3

2-1.

Powerplant Test stand. It is assumed that fabrication will take place at Direct Support/General Support or

similar facility with access to welding equipment and expertise. Fabrication is provided by system and in the

recommended sequence. Each subsystem begins with a suggested Bill Of Materials. If appropriate, the

respective M113 part number and NSN are provided. Throughout the fabrication process, items may be

purchased locally or cannibalized to expedite or make fabrication less expensive. All dimensions are given in

US measurements followed by Metric measurements in parenthesis.

SECTION II. FRAME AND MOUNTS

2-2.

may be mounted on a skid and moved with a forklift or the frame may be mounted on axles and wheels and

towed with a small tractor or similar apparatus.

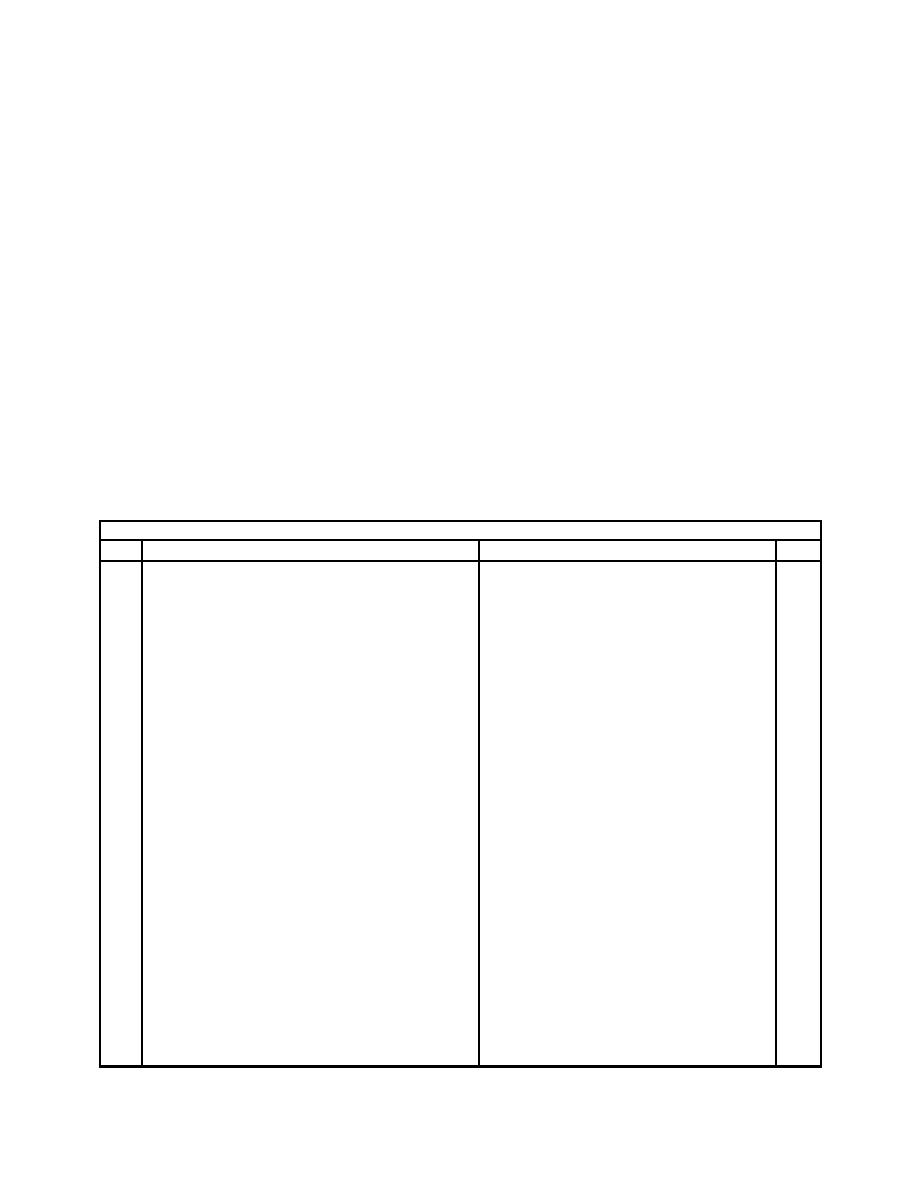

a. Frame Assembly

Bill Of Materials Location

Item

Nomenclature

Location

Qty

Main Frame

4" by 2" by 1/4" Rectangular Steel Tubing

1

96 inches (243.8 cm)

2

2

51 inches (129.5 cm)

2

3

48 inches (121.9 cm)

2

4

46 inches (116.8 cm)

2

5

20 inches (50.8 cm)

4

6

6 inches (15.2 cm)

1

7

4 inches (10.2 cm)

1

Transmission Mount (A3)

4" by 3" by 1/4" Steel Angle

8

32 inches (81.3 cm)

2

9

19 inches (48.3 cm)

2

Front Leg Mount

4" by 6" by 5/16" Angle

Rear Engine Battery Box

3" by 2" by 1/4" Rectangular Steel Tubing

10

10-1/2 inches (26.7 cm)

4

11

15-1/2 inches (39.4 cm)

4

12

18 inches (45.7 cm)

2

Forklift Pockets

4" by 6" by 3/8" Steel Tubing

Top Plate of Stand

1/4" Tread Plate

13

12 by 20 inches (30.5 by 50.8 cm)

4

14

18 by 20 inches (45.7 by 50.8 cm)

1

15

6 by 23 inches (15.2 by 58.4 cm)

1

16

4 by 23 inches (10.2 by 58.4 cm)

2

17

15 by 18 inches (38.1 by 45.7 cm)

1