TB 9-2350-368-25

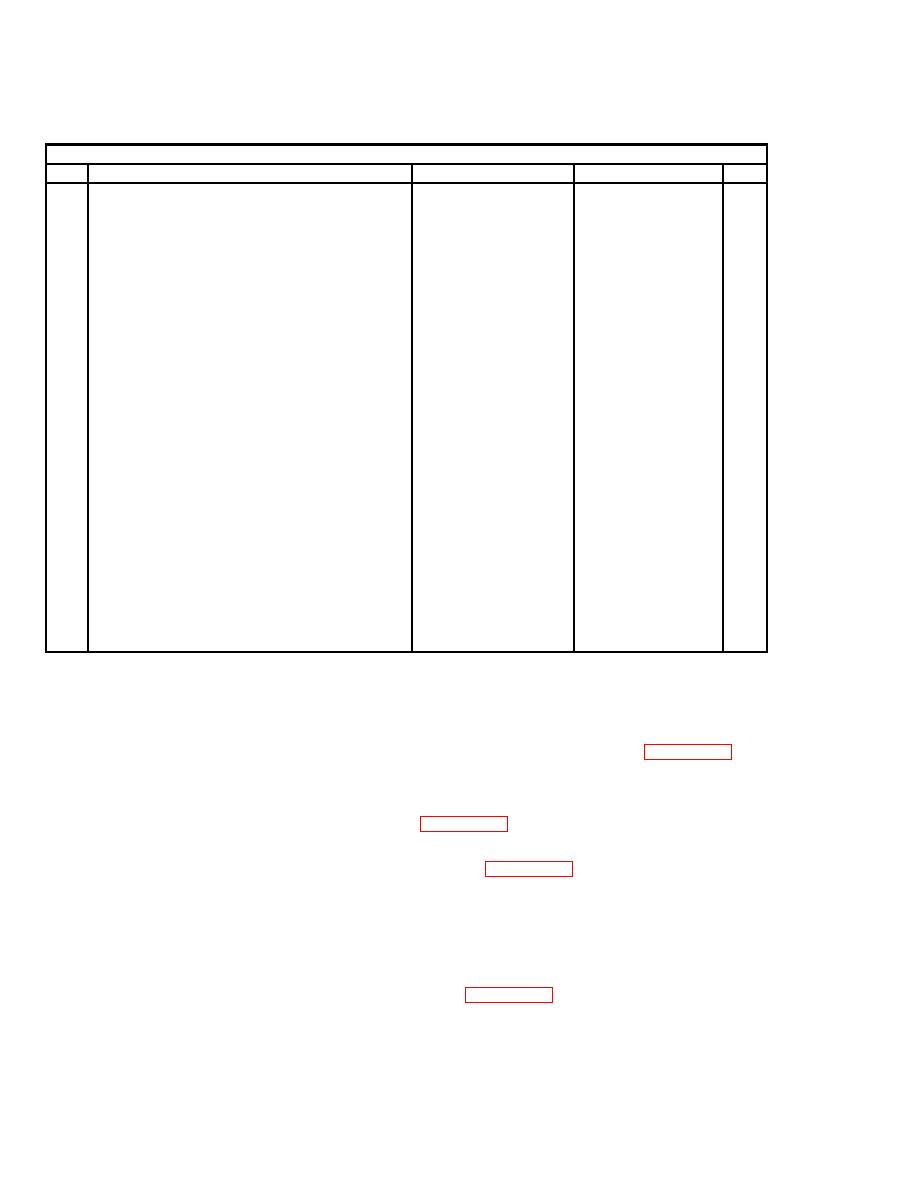

b. Brake Stall Test Tool

Bill Of Materials

Item

Nomenclature

Part Number

NSN

Qty

2" by 3" by 1/4" Steel Angle

1

10 inches (25.4 cm)

1

2

4 inches (10.2 cm)

1

1/4" Steel Plate

3

20 by 1 inch (50.8 by 2.5 cm)

1

4

1/4 by 3-1/4 inches (6.4 by 83 mm)

2

1/8" Steel Plate

5

6 by 1/8 inches (152 by 3.2 mm)

1

Rubber Hose

6

8 by 1 inch ID (20.3 by 2.5 cm)

1

7/16" ID Roll Steel

7

2 inches (5.1 cm)

1

Hardware/Components

8

Quick Release Pin

MS17984

1

9

Chain

1

10

Washer

MS27183-283

6

11

Nut

MS51922-18

3

12

Clevis Rod End Connector

MS35812-2

1

13

Screw

B1821BH038C300N

3

14

Screw

24617-9425094

2

15

Washer

23018199

2

1. Measure 9 inches on one side of steel angle (1) and 10 inches on the other side. Scribe a line joining the

marks.

2. Cut steel angle (1) at approximately 60 along scribed lines.

3. Measure 3 inches on one side of steel angle (2) and 4 inches on the other side. See Figure 2-28. Scribe a

line joining the marks.

4. Cut steel angle (2) at approximately 60 along scribed lines.

5. Weld steel angles (1) and (2) along 60 angle. See Figure 2-28.

6. Scribe a line one inch from end of 1/4-inch steel plate (3) and four inches from the one inch scribe line.

Scribe a line centered lengthwise (1/2 inch from edge). See Figure 2-28.

7. Drill two 3/8-inch diameter holes where scribe lines intersect.

8. Measure down the middle of 1/8-inch plate (4) and scribe a line.

9. Starting about 3/4-inch from end of 1/8-inch steel plate (4), scribe ten lines evenly spaced (approximately

every 29/64).

10. Drill ten 1/4-inch holes where scribe lines intersect. See Figure 2-28.

11. Bend 1/4 inch on both ends of 1/8-inch steel plate (4) approximately 90.

12. Using 1/8-inch plate (4) as template, drill ten 1/4-inch holes in 1/4-inch steel angle (1).

2-46