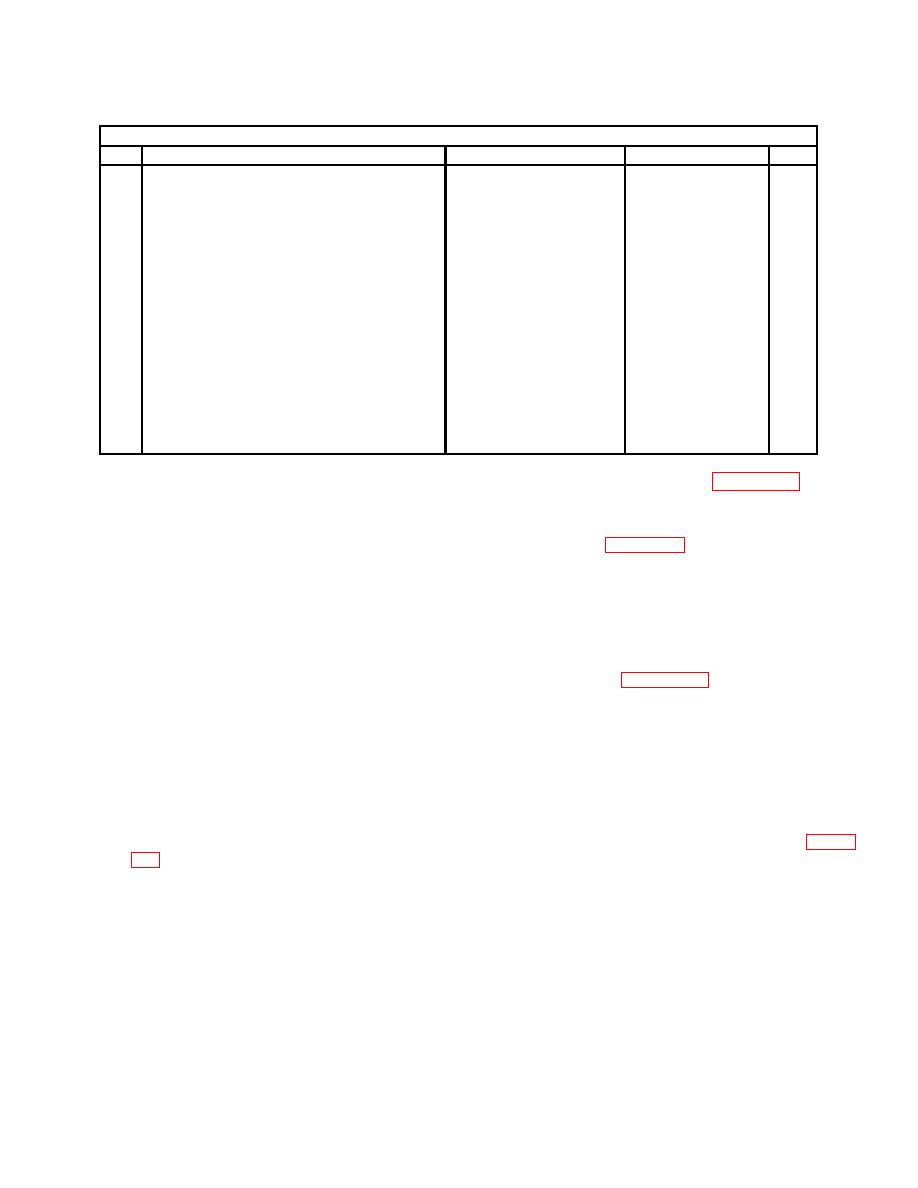

TB 9-2350-368-25

Bill Of Materials--Continued

Item

Nomenclature

Part Number

NSN

Qty

59 Tube Reducer

MS51534A12-8

2

60 Quick Disconnect Coupling Half

12297003-3

1

61 Nut

MS51860-58

2

62 Quick Disconnect Coupling Half

12297003-4

1

63 Elbow

MS51522A12

1

64 Nipple

MS51953-52

4730-00-861-8538

1

65 Gasket, Fuel Filler

8756391

5330-00-679-9729

1

66 Radiator

Any 2 1/2 or 5 Ton

1

Truck

67 Gasket

10932933

5330-00-058-9263

2

68 Elbow, Radiator

12253525

1

69 Hose, Radiator

11662999

A/R

70 Elbow

Fabricated

A/R

71 Screw

B1821BH025C100N

3

72 Screw

MS35206-281

12

73 Locknut

MS51922-2

12

1. Install 200-amp regulator (1) on floor plate under powerplant test stand frame, see Figures 2-12 and 2-

14, with four screws (2) and lockwashers (3). Connect ground lead (4), lockwasher (5), and nut (6) to

regulator. Connect ground lead (4) to mounting bracket with mounting screw (7) and lockwasher (5).

2. Install 100-amp regulator (8) on powerplant test stand floorplate (2, Figure 2-4), under powerplant test

stand frame with four screws (2) and lockwashers (3). Connect ground lead (4), lockwasher (5), and nut

(6) to regulator. Connect ground lead (4) to floorplate with mounting screw (7) and lockwasher (5).

Location is under powerplant test stand and wherever there is room to position it.

3. Install four batteries (9) in battery box under powerplant test stand frame. Install eight battery terminal

covers (10), four lug terminals (11), lug terminals (12), lead (13), and lead (14) on batteries (wired in

series/parallel). Connect two leads (14) between batteries positive terminals and bus bar. Connect two

leads (15) between batteries negative terminals and master switch. See Figure 2-14 for location of

batteries under powerplant test stand.

4. Install shunt (16) on battery box support with four screws (17), eight washers (18), and four locknuts

(19). Install electrical lead (20) on shunt with screw (31) and lockwasher (32). Connect other end to

battery support with screw (23), two washers (24), and locknut (25). Install electrical lead (20) on shunt

with screw (3) and lockwasher (22). Connect other end to master switch. Shunt cover is not necessary,

however if desired, you must fabricate it yourself or order shunt cover (26) and modify to use on your

powerplant test stand.

5. Install master switch (27) and identification plate (28) on powerplant test stand floor plate 4, see Figure

2-4. Use two screws (29) and locknut (30). Master switch is connected to battery negative terminal with

1/0 AGW lead and ground. Drill two 0.265-inch diameter holes. Distance from center to center of holes is

1.875 inch.

6. Install NATO slave receptacle (31), gasket (32), and insulator plate (33) on powerplant test stand frame,

or assemble (11674728) (need to attach mounting bracket to frame). Install NATO slave receptacle (31)

in mounting bracket with four screws (2), washers (34), and locknuts (35). Connect electrical lead (36)

circuit 49 between receptacle and bus bar and ground the other terminal.

7. Install two plastic terminal blocks (37) on battery box support with two screws (38) and lockwashers (39).

8

Install electrical bus bar (40) on two plastic terminal blocks (37) with two screws (23) and lockwashers

(41). Install two screws (42) and lockwashers (43) in electrical bus bar (40).

3-3