TM 43-0139

CPP designs, including inspection worksheet (para 4-3)

One (1) 6-foot steel measuring tape, graduated in sixteenths (or thirty-seconds) of an inch

One (1) 6-foot steel measuring tape, graduated in tenths of an inch

Small T-square and/or straight edge

Soapstone or chalk

Pen, pencils, colored pencils

Paper/notebook

One plumb bob, with string

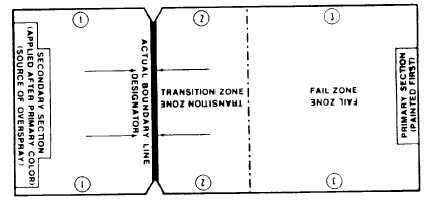

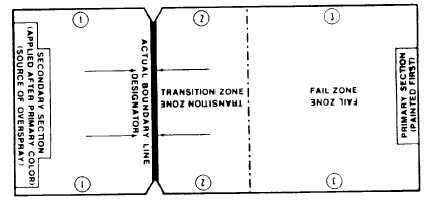

Overspray gauge (figure 4-2)

Figure 4-3. Overspray Gauge

4-12. LEVEL I INSPECTION

In this level of inspection, the inspector, from a distance of 50 feet or more from the item, visually compares the colors,

shapes and boundaries of the applied pattern to those of the design pattern, by using the following sequence of steps:

a.

Ensure the data on the identification plate of the item to be inspected corresponds to the data on the CPP

drawings. If not, the CPP inspection cannot be performed until the correct drawing set is obtained (para 4-3).

b.

With 2 different colored pencils, shade color areas #1 and #3 of the drawing set, including inspection worksheet.

c.

Begin with the right side view. If from that view the items 20 feet or less long, stand 50 feet from it. If item is over

20 feet but less than 40 feet in length, stand 75 feet from it. If item is longer than 40 feet. stand 100 feet from it.

d.

Compare the right side as drawn with the actual right side view of the item:

(1)

Ensure all black disruptive bands have been properly located on the item.

(2)

Verify comparative size and direction of black bands with those on drawing.

(3)

Ensure black boundary lines closely conform to the shape of boundaries depicted on CPP drawings.

(4)

Ensure all brown patches have been properly located on item.

(5)

Ensure contours are sharply defined, and shapes of brown patches closely conform with those on CPP

drawings.

e.

Document any failures (differences found between applied pattern and drawing pattern) as follows:

(1)

Mark failed area on item with chalk or soapstone.

4-7