TM 43-0139

5-8. ADDITIONAL SPRAY EQUIPMENT

a.

Compressors.

(1)

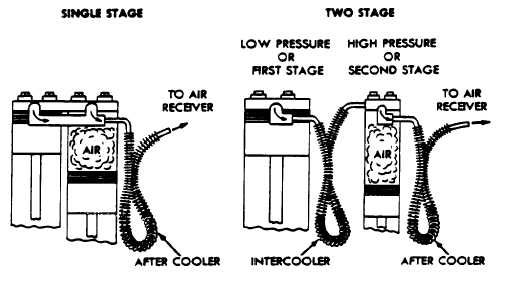

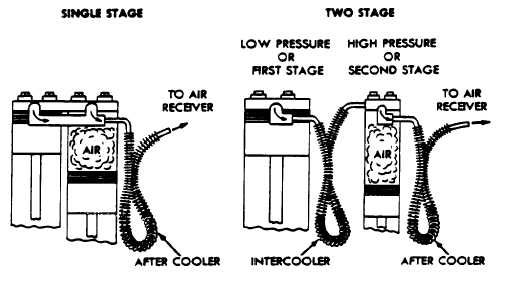

General. An air compressor is a mechanism designed to supply compressed air continuously at a

predetermined pressure and volume. Compressors designated for spray painting are of two general types: single-stage

and two-stage. These can be further divided into many other types, some of which are portable or stationary, unloader or

pressure-switch controlled, have horizontally or vertically mounted tanks, are air or water cooled, and have a gasoline

engine or an electric motor drive. Technical Manuals on air compressors are listed in AMC Pamphlet 750-9.

(a)

Single-stage compressors. A single-stage compressor (see figure 5-12) is one having one or two cylinders

in which air is drawn from the atmosphere, compressed to a usable pressure, and delivered through an after cooler to the

air receiver. Compressors of this type are intended for use where maximum pressures do not exceed 100 pounds per

square inch (psi).

(b)

Two-stage compressors. A two-stage compressor (see figure 5-12) is one in which a relatively large

cylinder first compresses the air to an intermediate pressure. Air compressed to this point is delivered through an

intercooler to a small cylinder where it is compressed to the final pressure. It is then delivered through an after cooler to

the air receiver. A system of this type is intended for use where required pressures exceed 100 psi. Such pressures will

be encountered infrequently in everyday painting.

(c)

Gasoline engine drive. Gasoline engines of approximately three to five horsepower are used with

compressors under the following conditions: where electric current is not available; where spray painting systems are

used in localities served with different types of current; and in localities where insufficient current is supplied.

(d)

Electric motor drive. A majority of spray painting compressors are powered by electric motors of onefourth

to five horsepower. The use of a system of this type is confined to locations in which the proper current is available.

Electric motor-drive is generally chosen for more or less permanent installations, while a gasoline drive is preferred where

portability is the prime consideration.

Figure 5-12. Single and Two-Stage Compressors

5-16