TM 43-0139

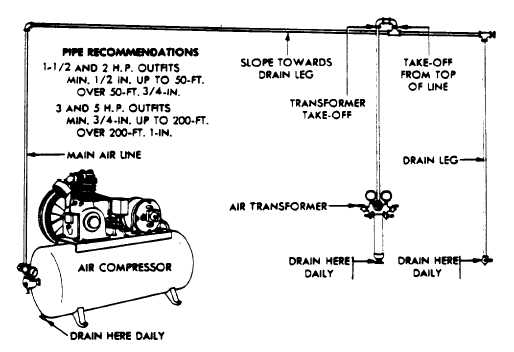

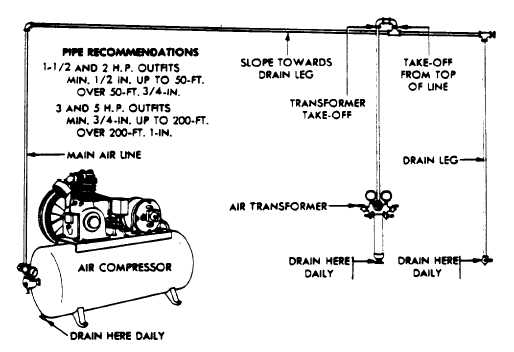

Figure 5-13. Air Transformer Installations

(a)

Install the transformer at least 15 feet from the compressor.

(b)

Air takeoffs from the compressor line to the transformer should be from the top of the line.

(c)

The compressor air line to which the air transformer takeoff is attached should slant toward a

permanently installed drain leg which should be drained daily. In localities where regulated air is available and only

cleaning and filtering are needed, an air conditioner may be used to supplant the air transformer. The size of all

necessary air lines is given in figure 5-13.

(4)

Filter replacement. The filter pack in an air transformer should be inspected and replaced whenever it

shows signs of becoming clogged by dirt or oil.

5-9. SHOP EQUIPMENT

a.

Paint Booths.

(1)

A paint booth is designed to collect, filter, and exhaust the fumes arising from the use of spray paint

equipment. Due to Occupational Safety and Health Administration (OSHA), Environmental Protection Agency (EPA), and

specific state and local requirements, any large scale (more than touchup) painting must be done in a paint booth. This is

to minimize the release of toxic fumes into the environment and protect workers.

(2)

Spray booths can be classified into two basic designs based on direction of airflow:

(a)

Sidedraft Booths. Sidedraft booths have horizontal airflow. These booths take advantage of

momentum of the spray mist and can be used when painting small to medium articles.

5-21