TM 5-3655-210-12

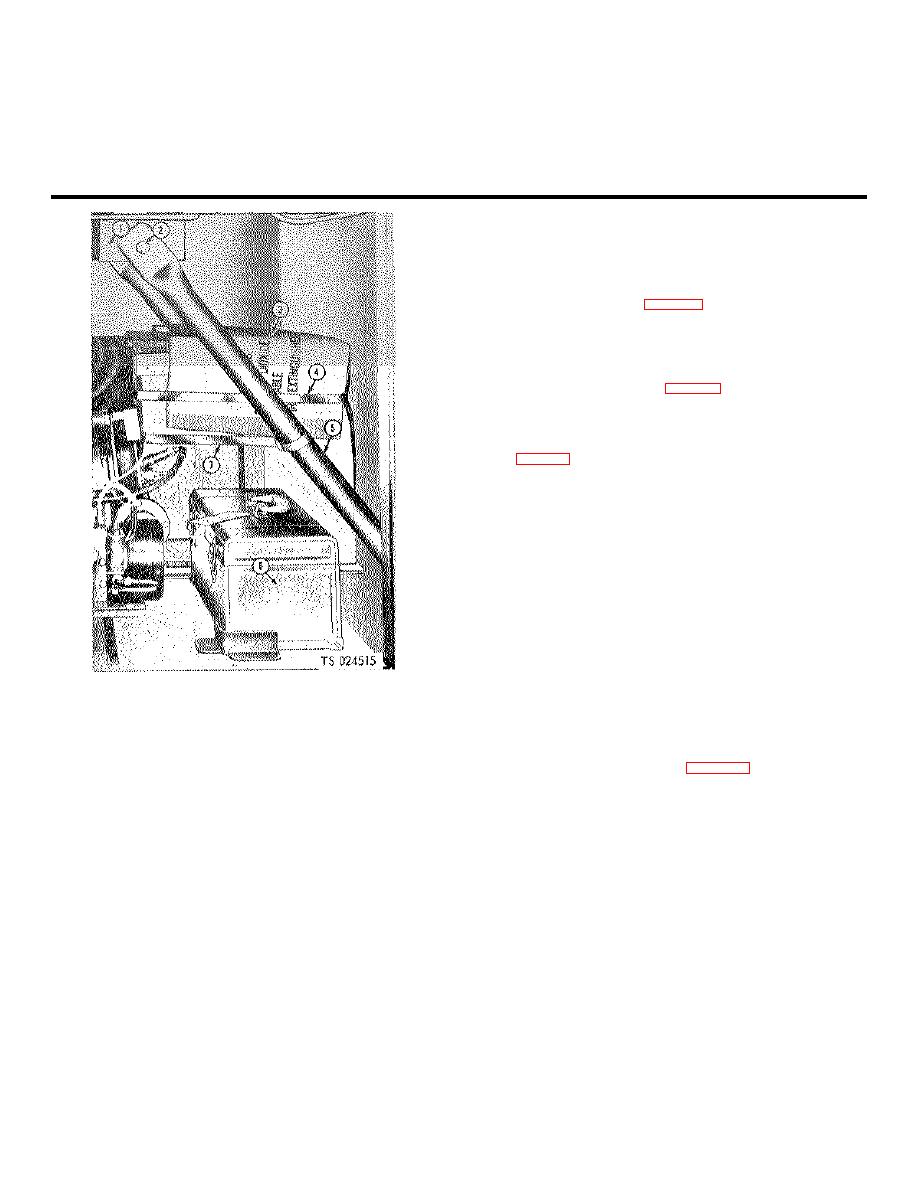

1.

Coolant line

6.

Housing

11.

Coolant line

16.

Pipe union

21.

Wiring harness

26.

Limit switch

2.

Machine screw

7.

Coolant line

12.

Pipe plug

17.

Saddle stand

22.

U-bolt

27.

Limit switch cover

3.

Machine screw

8.

Tube nut

13.

Nipple

18.

Capscrew

23.

Bracket

28.

Lockwasher

4.

Dome light base

9.

Bracket

14.

Tee

19.

Coolant pump

24.

Nut

29.

Coolant line

5.

Dome light lens

10.

Connector

15.

Nipple

20.

Coolant pump lead

25.

Machine screw

Figure 3-9 - Continued.

3-18.

Tires And Tubes

Inspect tires for wear, cuts which damage the cords of the

carcass fabric, and inflation pressure, which should be 75 pounds per

square inch (5.2725 kg per sq cm).

3-19.

Pintle

Check that pintle assembly (7, fig. 3-12) unlatches readily and latches

easily and securely. Clean as necessary to free up sticky mechanism.

3-20.

Landing Gear

W ash or steam clean landing gear for inspection. Check for

loose screws and nuts, damaged threads, corrosion, physical damage,

leaking lubricant from gear box (7, fig. 3-13). Refer maintenance beyond

lubrication to organizational maintenace.

3-21.

Winterization Equipment

Operate conversion and storage gage line heater switches (6

and 7, fig. 3-5). If operating lights (5) do not light, replace bulbs as

follows: To replace a burned out lamp, unscrew the lens from the front of

the light, replace the lamp and screw the lens back in place.

3-22.

Data Plates and Instruction Holders

Inspect data, plates for security of mounting and legibility of

data. Inspect instruction holders for condition and that current copies of

applicable instructions are installed.

3-23.

Motor Starter and Protective Devices

Inspect exterior of starter (fig. 3-14) and reversing switch for general

condition, loose attaching parts and condition of external wiring.

3-24.

Gages, Lines, and Fittings

Inspect instruments and gages for proper indication as

described, security of mounting and freedom from leakage (if applicable).

1. Landing jack brace,

4.

Band

Inspect gages and associated lines for physical damage.

mounting bracket

5.

Landing jack brace

3-25.

Conversion Heater

2. Capscrew

6.

Tool box'

Inspect heater fluid lines (fig. 3-15) and their fittings for leaks.

3. Packing boxes

7.

Band

Check sight glass indications for quantity of heater fluid in tank. Operate

heater and check that exhaust from combustion is free of smoke.

Figure 3-10. Electrolyte and batteries stored for shipment

3-26.

Cylinder Filling Compressor

a.

Service compressor (26, fig. 3-16) according to LO 5-

Electrolyte must cover the plates by at least /4 inch (.635 cm).

3655-210-12.

WARNING

Do not overfill the batteries or splash electrolyte as it is

an acid and can cause personal injury.

(7)

Replace the twelve cell caps and wash off any

acid that may have spilled.

3-17.

Power Transfer Equipment

Check that transfer pump drive belt can be deflected no more

than 1 in. (2.54 cm) at midpoint by thumb pressure; all other belts, no

more than 1/2 in (3.81 cm). Lubricate in accordance with LO 5-3655-

210-12.

3-13