TM 5-3655-210-12

1.

8.

Lockwasher

2.

Elbow

9.

Capscrew

15.

Belt tightener mounting

21.

Nut, terminal, upper

3.

Pipe nipple

10.

Battery lead

16.

Capscrew

22.

Lead

4.

Pipe coupling

11.

Lockwasher

17.

Nut, terminal, lower

23.

Nut, U-bolt clamp

5.

Shroud

12.

Capscrew

18.

Lockwasher

24.

Bracket

6.

Flywheel cover

13.

Bracket

19.

Lead

25.

Clamp (U-bolt)

7.

Machine screw

14.

Tailpipe tube

20.

Lead

26.

Figure 3-4 - Continued.

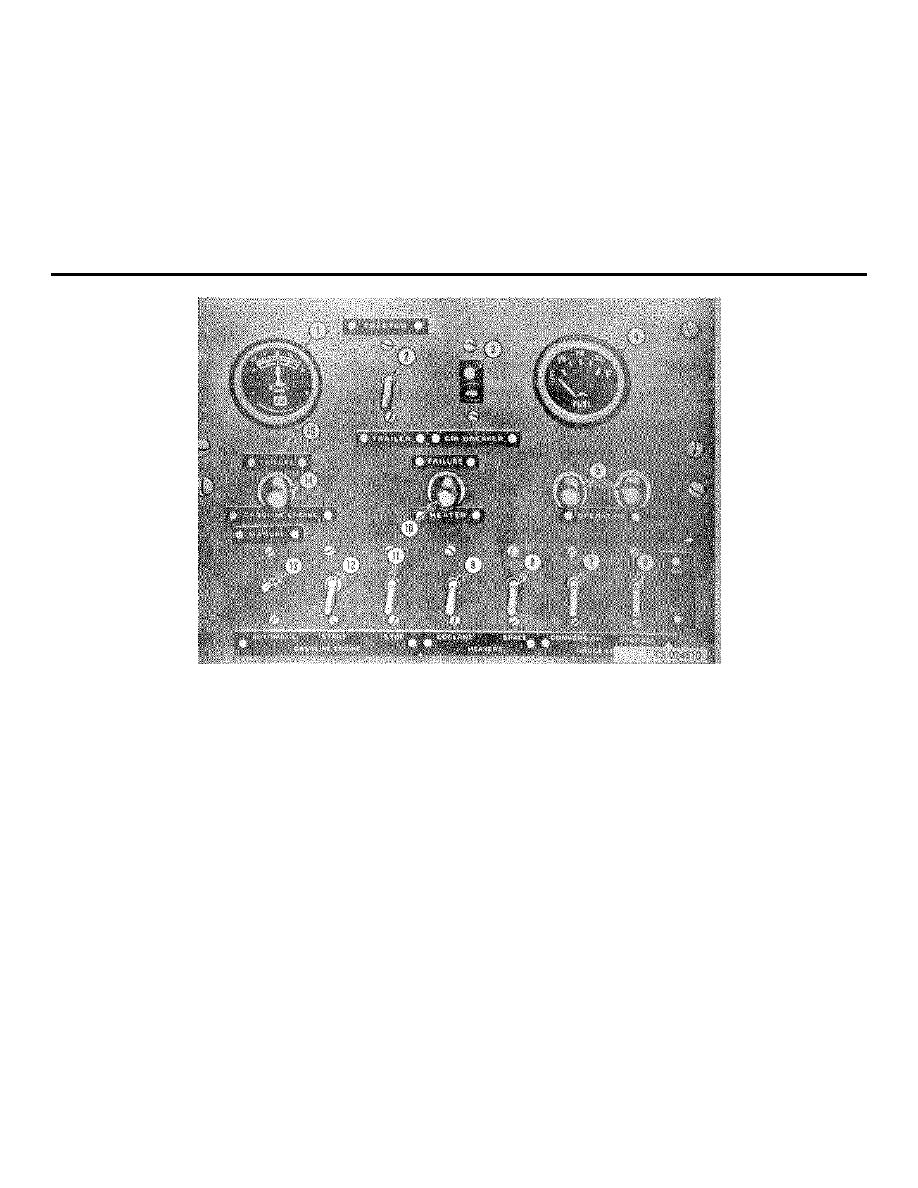

1.

9.

Conversion heater control switch

2.

Electrical control switch (tractor or trailer)

10.

Conversion heater failure light

3.

Circuit breaker

11.

Gasoline engine manual stop switch

4.

Fuel indicator gage

12.

Gasoline engine manual starter switch

5.

Gage lines operating lights

13.

Gasoline engine control switch for automatic or manual

6.

Storage vessel gage line switch

control

7.

Conversion vessel gage line switch

14.

Gasoline engine failure light

8.

Compartment heater control switch

15.

Engine control panel

WARNING

(2) To replace lamp, loosen two

Dry cleaning solvent, P-D-680 or P-

screws (3) holding lens (5) to base (4), turn

S661 used to clean parts is

lens to remove it, and replace lamp.

potentially dangerous to personnel

Reposition lens and tighten screws.

d. Failure and Gage Line Lights

and property. Use in a well-ventilated

(1) Removal. Tag the wires of the

area as the fumes are dangerous if

light to be removed. Then remove the nut and

inhaled.

Avoid repeated and

lockwasher securing the light to the panel and

prolonged skin contact. Do not use

slide the assembly out the front of the panel.

near open flame or excessive heat.

(2) Cleaning,

Inspection,

and

Flash point of solvent is 100F. - 138F.

Repair.

(38C. - 59C.).

3-9