TM 5-3655-210-12

Section II. PREVENTIVE MAINTENANCE

CHECKS AND SERVICES (PMCS)

3-4.

General

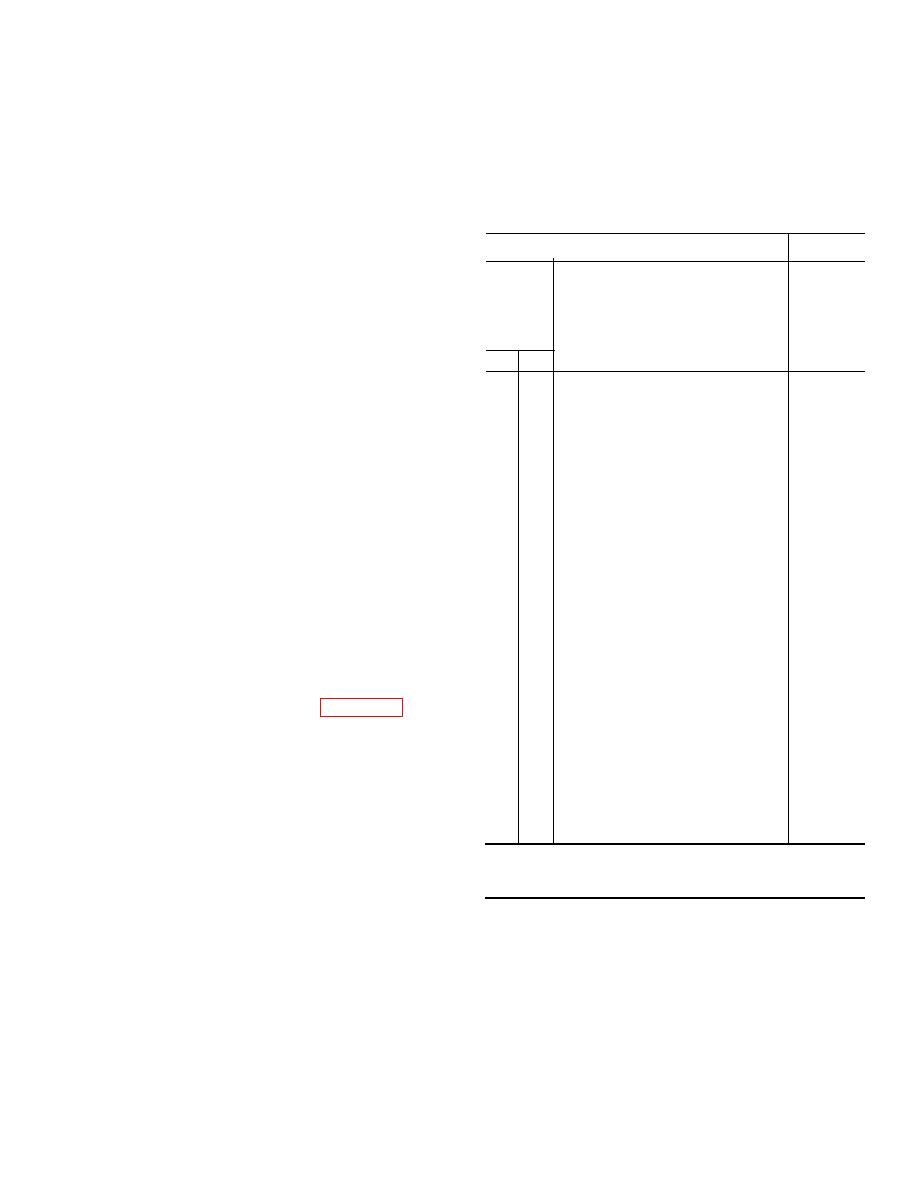

Table 3-1. Operator/Crew Preventive

Maintenance Checks and Services

To insure that the conversion and

storage unit is ready for operation at all times,

D-Daily

W-Weekly

it must be inspected systematically so that

Total Man-Hours Required: 3.0

defects may be discovered and corrected

before they result in serious damage or failure.

Internal

and

Item to be Inspected

W ork

Defects discovered during operation of the unit

Sequence

Procedure

Time

shall be noted for future correction, to be made

No.

as soon as operation has ceased.

Stop

D

W

(M/H)

operation immediately if a deficiency is noted

which would damage the equipment if

1

GASOLINE ENGINE CRANKCASE

operation were continued. All deficiencies and

Service per L05-3655-210-12.

1.0

shortcomings will be recorded together with

2

FUEL PUMP FILTER (SERIAL NOS.

L-1475-T THROUGH L-1478-T)

the corrective action taken On DA Form 2404

Inspect filter through glass bowl.

(Equipment Inspection and Maintenance

Remove any foreign matter from

Worksheet)

at

the

earliest

possible

screen.

0.2

3

DRIVE BELTS

opportunity.

Check that transfer pump belt ten-

sion permits only about 1 in. (2.54

3-5. Daily

Preventive

Maintenance

cm) deflection under thumb pressure

at midpoint between pulleys; tension

Services

of other belts, about 1 1/2 in.

(3.81 cm) deflection under the same

This paragraph contains an illustrated

test.

0.2

tabulated listing of preventive maintenance

4

GASTANK

Fill with REGULAR grade

services which must be performed by the

gasoline, 74 octane preferred.

0.3

operator.

The item numbers are listed

5

CYLINDER FILLING UNIT

consecutively and indicate the sequence of

Service crankcase per figure 3-1.

0.5

6

REFRIGERATION COMPRESSOR

minimum requirements. Refer to Table 3-1 for

Service crankcase per figure 3-1.

0.5

the daily preventive maintenance services.

7

CONTROLS AND INSTRUMENTS

With the unit operating inspect

for improper operation. Normal

operating ranges for instruments

are as follows:

DC Ammeter (on engine

control panel)

0-20 amps

Fuel Gage

"E" to "F"

0.3

NOTE

During operation observe for any unusual noise or vibration.

3-4