TM 5-3655-210-12

CHAPTER 4

ORGANIZATIONAL MAINTENANCE INSTRUCTIONS

Section I. SERVICE UPON RECEIPT OF MATERIAL

4-1.

Unloading New Conversion And Storage Unit

(3)

Lower the landing jacks to support the weight of

a.

General. The conversion and storage units are shipped

the front of the trailer, and remove all tie-down cable or bands, wheel and

body blocks, and other bracing.

on railroad flatcars, securely blocked (fig. 4-1) and lashed with 1/2 inch

(4)

Back an air brake equipped tractor up to the ramp

(1.27 cm) steel cable or 2 inch (5.08cm) X 0.050 inch (0.127cm) high

to the trailer, and couple the tractor air and electrical connections to the

tension bands. They are completely assembled. To prevent possible loss

trailer. Be sure the condensation drain petcock on the air reservoir is

in transit, the freon gas charge is pumped down from the refrigeration unit

closed, and carefully tow the unit off the flatcar.

to the receiver tank. The crankcases of the gasoline engine, cylinder

4-2.

Unpacking New Conversion And Storage Unit

filling unit, and refrigerating unit are filled to the proper level. The tool box,

Accessories

with tools, and the electrolyte for the batteries, are secured in the storage

a.

compartment. The pressure vessels are drained of carbon dioxide liquid

and filled with carbon dioxide vapor at 3 to 5 psi (pounds per square inch)

items that are furnished with and are

(.2109 to .3515 kg per sq cm).

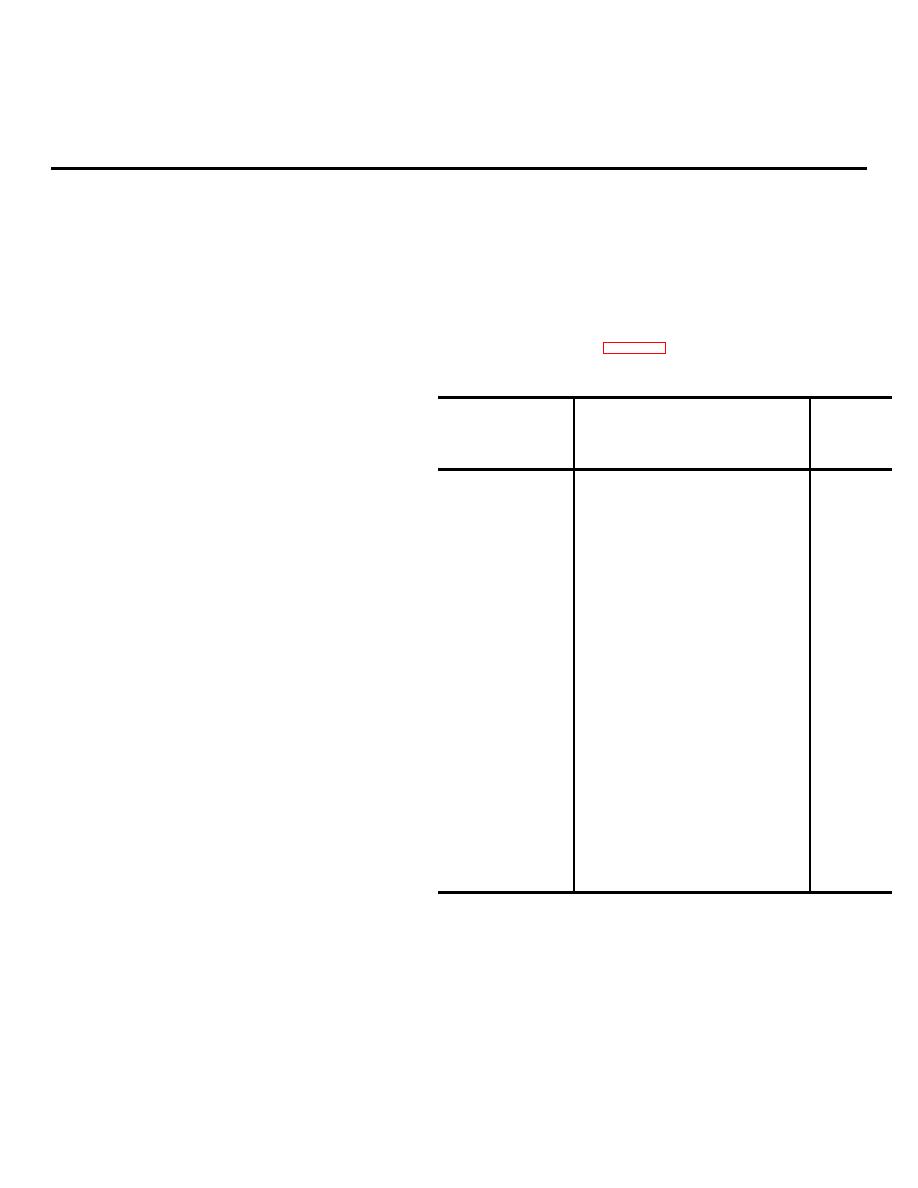

Table 4-1. Separate Packed Items

b.

Unloading With Lifting Device.

Quantity

(1)

Remove the cables or bands (fig. 4-1) securing

National

Description

Furnished

the rear of the unit to the flatcar.

Stock

w/equip-

(2)

Remove the cables or bands securing the front of

Number

ment

the trailer.

(3)

Remove the blocking from the side of the wheels

and the blocking from in front of, and behind the wheels.

(4)

If a crane is to be used remove the four lifting eye

6140-00-057-2554

Battery, storage, 12V

2 ea.

covers by removing twelve sheet metal screws and lockwashers securing

6150-00-435-2322

Cable, electrical, main-power,

1 ea.

each cover to the tank body.

100 ft. (3000cm) w/conn

(5)

Remove the insulation blocks from under the

(90129)x8702-17

covers.

Chock, wheel (07464) 3597

2 ea.

(6)

Unscrew four tie-down rings from the trailer and

Dichlorodifluoromethane, fed.

1 ea.

install them in the lifting eye holes at the top of the tank body.

BB-F-671, type 12,

(7)

Attach the slings and carefully remove the unit

25 LB. (11.25kg) cylinder.

from the flatcar with a crane of ample lifting capacity.

Ground, rod assembly w/ wire lug

1 ea.

(8)

Remove the slings, replace the insulation and

and clamp (07464) 3598.

secure each cover with the twelve sheet metal screws and lockwashers.

c.

Unloading By Use of Ramp.

3655-00-084-0464

Hose assembly, C02, cylinder

2 ea.

(1)

Place an unloading ramp at the end of the flatcar.

filling 1/4"x6" (.635 x 15.24cm)

(2)

Block the flatcar wheels with 6 x 6 inch (15.24 x

(07464) 126200

15.24cm) timbers on each side.

3655-00-653-5713

Hose assembly, C02, transfer,

1 ea.

1" (2.54cm), ID, 50' (1500cm)

Ig. with 1/2" (1.27cm) cap-

tive adapter.

4720-00-653-5717

Hose assembly, C02, transfer,

1 ea.

1-1/2"(3.81cm) ID, 50' (1500cm)

Ig. with 3/4" (1.905cm) captive

adapter

Scale, dial indicating,

1 ea.

400 LB (180 kg)

(07464) 559381.

Sulfuric acid, electrolyte

4 gal.

(15.2

liters)

4-1