TM 5-3655-210-12

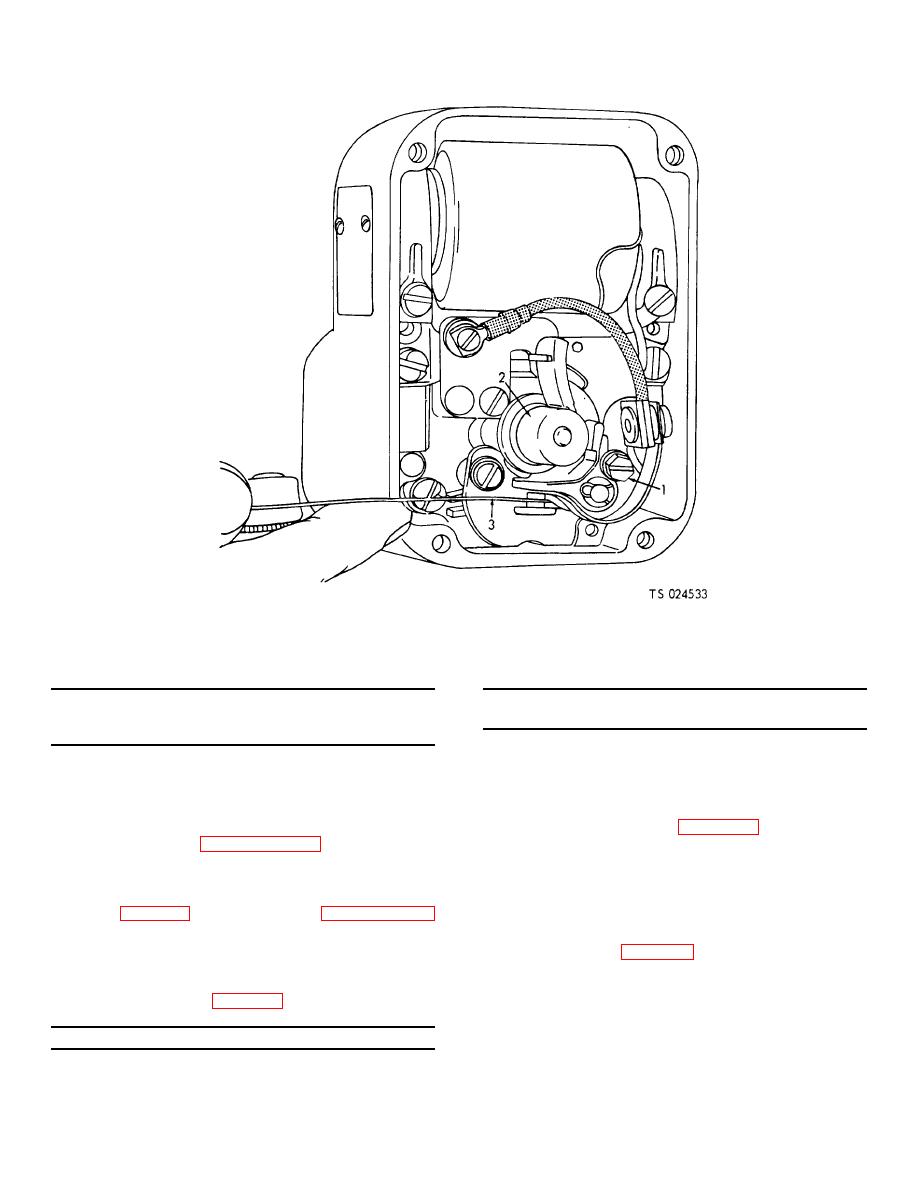

1. Screw

2. Rotor

3. Feeler gage

Figure 4-9. Checking for correct breaker point gap.

Test or Inspection

Malfunction

Corrective Action

Test or Inspection

Corrective Action

4. ENGINE BACKFIRES

3. ENGINE KNOCKS

Step 1. Listen for irregular engine performance and

Step 1. Check to see if oil level is low.

check exhaust for excessive black smoke

Refill.

indicating gasoline mixture being too lean.

Step 2. Check panel to see if engine is operating under

Adjust the carburetor by turning idle

adjusting screw (1, fig. 4-12) as needed to

heavy load at low speed.

Adjust the governor, paragraph 4-27.

get smoothest idle possible.

Step 3. Check for the running spark advance mark

Step 2. Listen for sticking inlet valves (missing engine)

being advanced too far by removing screws (1,

(chattering noise) and check for possible

fig. 4-10) and screen (2). Observe timing mark

backfire.

Adjust valves as follows:

(1, fig. 4-11) Time the magneto, paragraph 4-40.

Step 4. Check for a loose flywheel by removing the

a. Turn the crankshaft over by hand until

screen (fig. 4-10) and checking for a loose nut

the lifter (6, fig. 4-13) that is to be adjusted is

or key out of position.

at its lowest position.

Place key in position in slot and tighten

b. Insert 0.012 in. (.0305cm) feeler gage (5)

flywheel nut (2, fig. 4-11).

between the valve stem (8) and lifter screw

(7). Hold lifter (6) with wrench, and turn lifter

Malfunction

adjusting screw into or out of the lifter with

4-13