TM 5-3655-210-12

Malfunction

Test or Inspection

Corrective Action

5.

Engine Overheats

Step 1. Check engine for hard starting or blow back

indicating possible ignition spark out of time.

Re-time the engine (para. 4-40).

Step 2. Check for part of the air shroud removed from the

engine.

Replace missing parts (para. 4-64).

Step 3. Check for restrictions in the exhaust.

6.

Compression Low

Step 1. Inspect for a loose or broken spark plug.

Tighten spark plug. Replace a broken spark plug

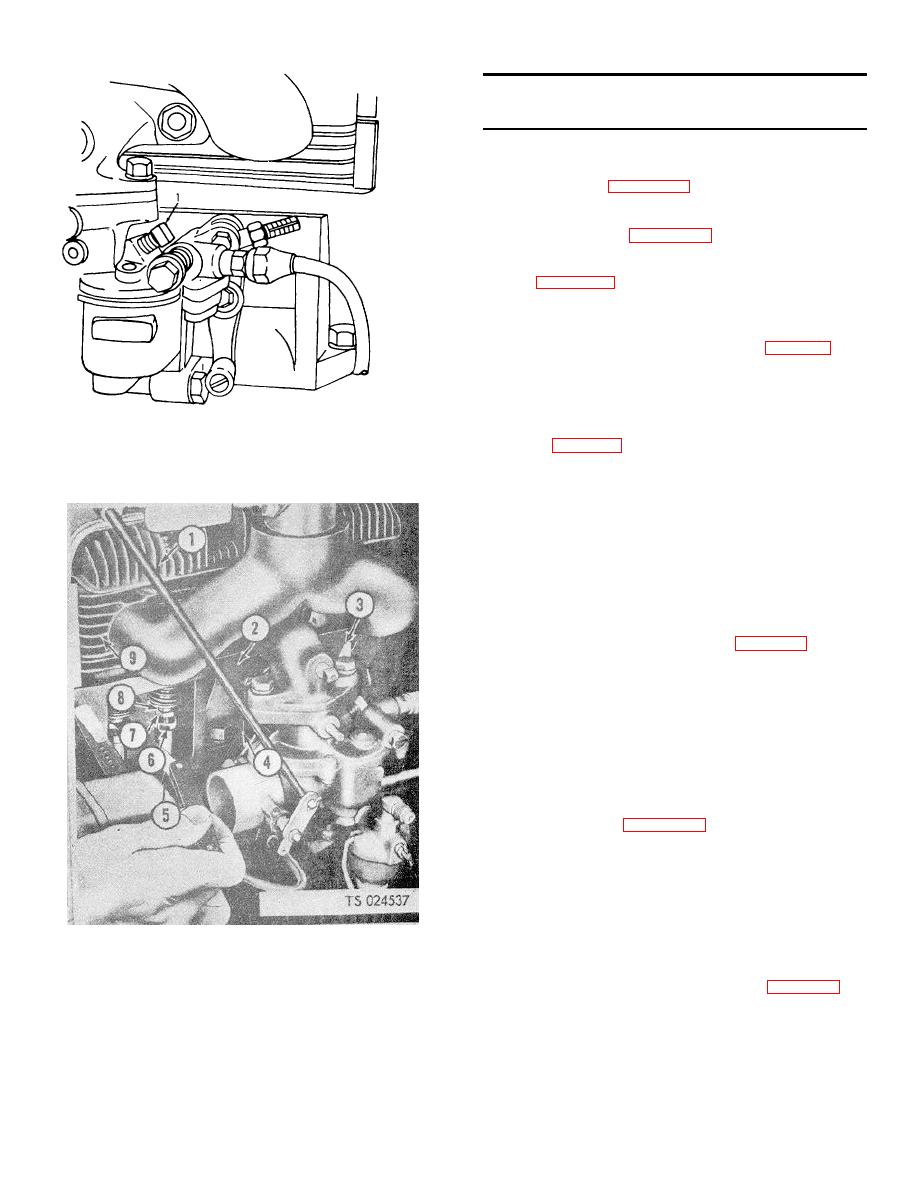

by removing the coupling nut (2, fig. 4-8) and

removing plug (1).

Step 2. Check the valve adjustment with an 0.012 in.

(0.0305cm) feeler gage.

Adjust the valves as follows:

a. Turn the crankshaft over by hand until the lifter

1. Screw

TS 024536

(6, fig. 4-13) that is to be adjusted is at its lowest

Figure 4-12. Idle adjusting screw.

position.

b. Insert 0.012 in. (.0305cm) feeler gage (5)

between the valve stem (8) and lifter screw (7).

Hold lifter (6) with wrench, and turn lifter

adjusting screw into or out of the lifter with

another wrench until the correct clearance is

obtained. A slight drag should be felt as the

feeler gage is moved back and forth.

7.

Power Loss In Engine

Step 1. Check for a partly closed carburetor choke.

Open choke as follows:

so that there is still enough drag to rotate the

choke control shaft.

b. Lift up on the control lever (2) until the

carburetor choke control lever (3) is in the up, or

closed position.

c. Tighten the clamp screw (1).

d When the lever (2) is released it should go back

to the intermediate position.

Step 2. Inspect for dirty air cleaner parts.

Remove, disassembly and clean or replace parts

as necessary (para. 4-26).

Step 3. Check instruments and observe sluggish engine

running (overload).

Correct operation of cylinder filling unit

8.

Pressure Vessel Pressure Too High, Alarm Bell

Does Not Ring

Step 1. Inspect tank alarm pressure switch out of adjustment

1.

Head

6.

Valve lifter

(The correct setting is 305 on the high side (knob 5) and 295

2.

Air shroud heat deflector

7.

Adjusting screw

on the low side (knob 6).

3.

Valve cover

8.

Valve stem

Adjust setting of the pressure switch as follows:

4.

Gasket

9.

Block

Adjust the tank pressure switches (4, fig. 4-15) by

turning the adjusting knobs (5 and 6) to the desired

5.

Feeler gage

setting on the scale. Set the pressure switch (8),

Figure 4-13. Tappet adjustment.

connected to the conversion heater, at 275 on the

high side and 260 on the low side.

4-15