TM 5-3655-210-12

Malfunction

Test or Inspection

Corrective Action

another wrench until the correct

clearance is obtained. A slight drag

should be felt as the feeler gage is

moved back and forth.

Step 3. Test and inspect spark plugs as follows:

a Use a feeler gage and see if plugs have the

proper gap. Plugs should indicate an 0.030 in.

(.0762cm) gap.

and spark plugs (1). Visually inspect plugs for

carbon, corrosion and excessive dirt deposits.

c. Test spark plugs by holding the plug about

1/4 in. (0.63cm) away from cylinder head. A

bright blue spark should jump from the tip of

plug to the cylinder head.

Clean, adjust or replace the spark plugs as

follows:

a, Clean by sand blasting.

b. Adjust plug by bending the electrode up

or down as necessary until 0.030 in. feeler

gage fits the gap.

1. Screw

2. Screen

TS 024534

c. Install new plugs (1, fig. 4-8) and secure

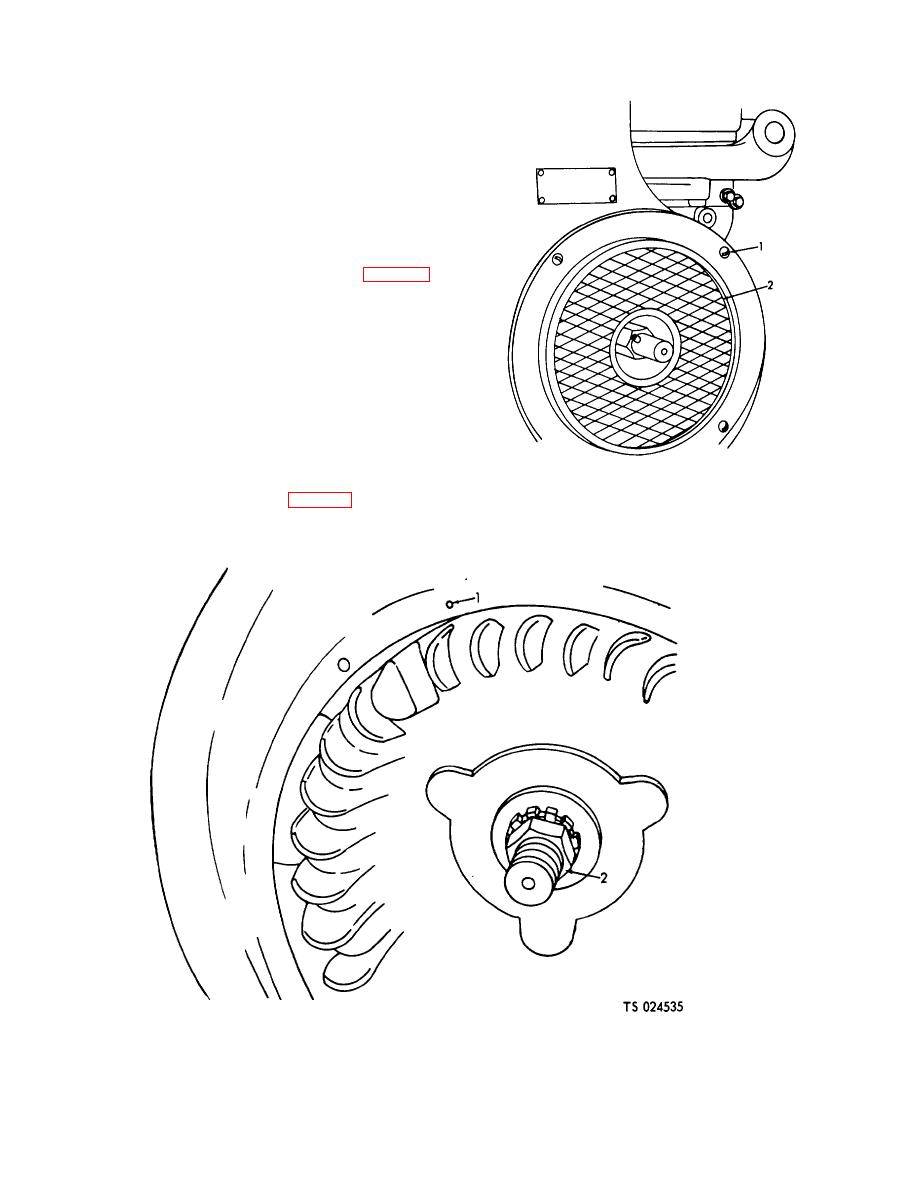

Figure 4-10. Flywheel screen, removal.

with nuts (2).

1. Running spark advance mark

2. Flywheel nut

Figure 4-11. Flywheel timing marks

4-14