TM 5-3655-210-12

(3) Replace the oil tube.

the shaft that is pressed into the timing gear cover (21,

(4) Replace the spring (17, fig. 4-24) in the

fig. 4-27).

WARNING

proper hole in the lever (18).

Dry cleaning solvent, P-D-680 or P-S-661, used to

(5) Slide the governor control rod into the lever

clean parts is potentially dangerous to personnel

(18) and secure with the cotter pin.

d. Adjustment. The rod from the governor to the

and property. Use in a well-ventilated area as the

fumes are dangerous if inhaled. Avoid repeated and

carburetor must be adjusted to the proper length. With

the engine stopped, the governor spring (17) will hold

prolonged skin contact. Do not use near open

the flyweights "IN" and the rod must be of such length as

flame or excessive heat. Flash point of solvent is

to hold the carburetor throttle wide open at that point.

100F.-138F. (38C.-59C.)

To check the accuracy of this adjustment, remove the

b. Cleaning, Inspection and Repair. Wash all parts

cotter pin securing the rod to the lever (18) and slide the

thoroughly in a cleaning solvent. Inspect the capscrews

rod from the lever. Push the rod toward the carburetor

for damaged threads. Clean the gasket mating surfaces

as far as possible. This will fully open the throttle. The

on the governor housing and the gear cover spacer.

bent end of the throttle rod should now line up exactly

Inspect the housing for cracks and leaks. Inspect the

with the hole in the lever (18). If it does not, screw the

shim washer for excessive wear. Inspect the flyweight

rod in or out of the swivel block on the carburetor lever

and thrust sleeve assembly for bearing, gear, and

until it is lined up properly. Position the rod in the

bushing wear. Replace all damaged parts. Replace the

governor lever and secure with the cotter pin.

gasket.

4-28. Fuel Pump And Fuel Strainer (Serial Nos.L-

c. Installation.

1475-T through L-1478-T.

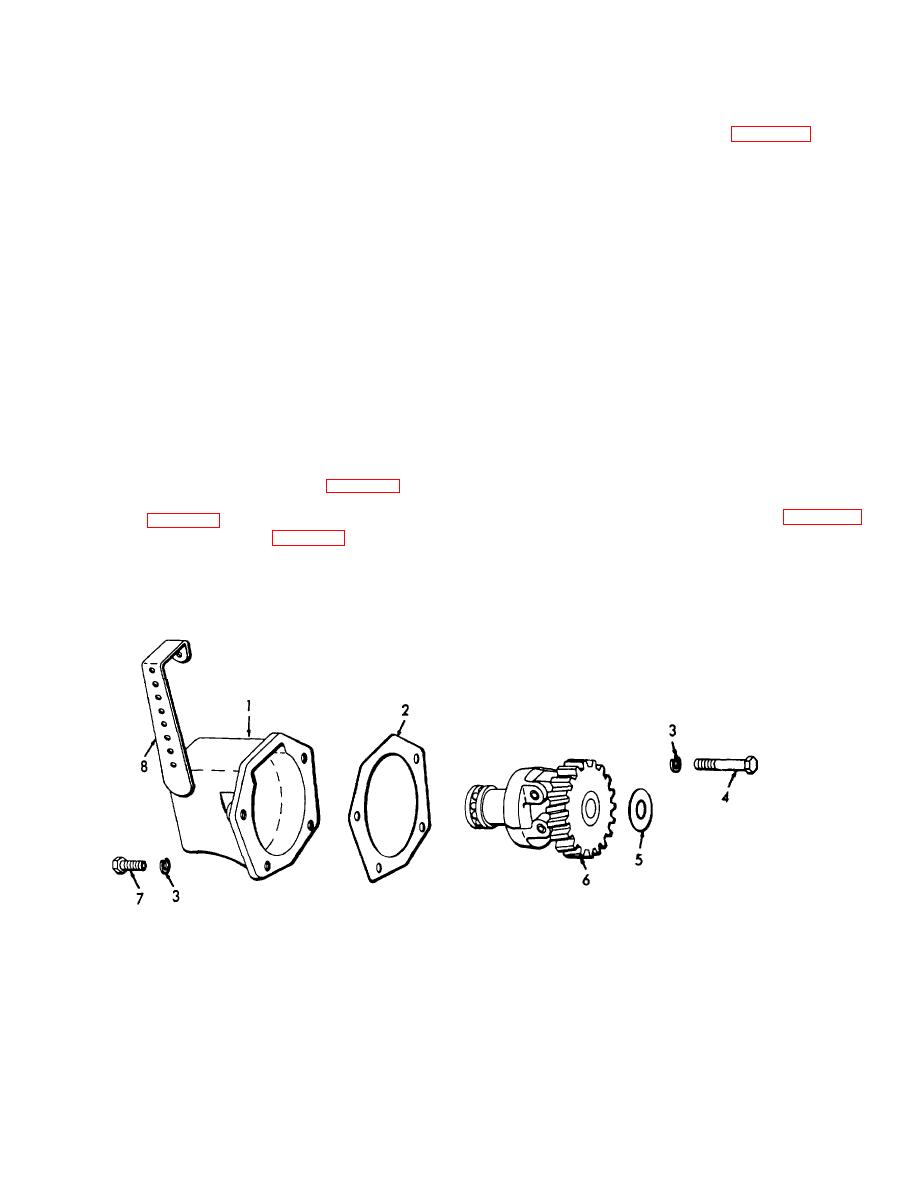

(1) Position the shim washer (5, fig. 4-29) and

a. Removal and Disassembly.

the flyweight assembly (6) on the shaft in the timing

(1) Loosen the two tube nuts (10, fig. 4-24)

gear cover (21, fig. 4-27).

securing the fuel tube (11) to the carburetor (16) and the

(2) Position the gasket(2, fig. 4-29) and housing

fuel pump and remove the tube.

(1) and secure, with the four lockwashers (3), the two

(2) Unscrew the tube nut securing the main fuel

machine bolts (4) through the timing gear cover and the

tube to the fuel strainer and push the fuel tube out of

two capscrews (7) through the governor housing.

the way.

TS 024554

1.

Housing

5.

Shim washer

2.

Gasket

6.

Flyweight and thrust sleeve assembly

3.

Lockwasher

7.

Capscrew

4.

Machine bolt

8.

Control arm

Figure 4-29. Governor, partially exploded view.

4-35