TM 5-3655-210-12

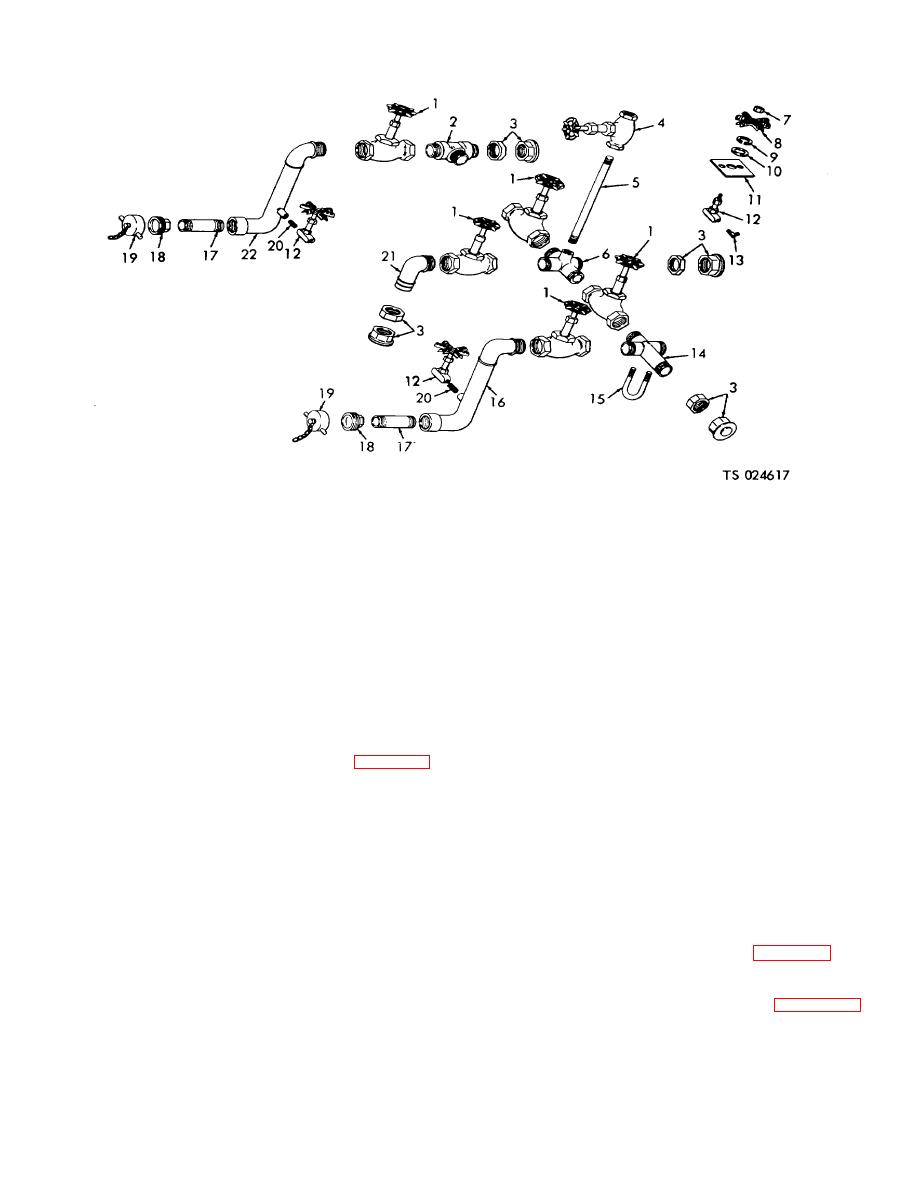

1.

Valve

2.

Tee assembly

9. Lockwasher

16. Elbow assembly adapter

3.

2/3 union

10. Flatwasher

17. Nipple

4.

Valve

11. Bracket

18: 1/3 union

5.

Nipple

12. Valve (3) (includes items (7) and (8)

19. Cap (2)

6.

Cross assembly

13. Adapter

20. Nipple

7.

Nut

14. Cross assembly

21. Elbow assembly

8.

Handle

15. U-bolt

22. Elbow assembly adapter

Figure 4-90. CO2, liquid manifold, exploded view.

c. Cleaning, Inspection and Repair. Wash all parts

(6) Remove the four nuts (20) bevel washers

(21) and the two U-bolts (18) securing the cylinder filling

in a cleaning solvent. Inspect the valves for loose nuts,

manifold to the liquid manifold.

damaged threads, or any other damage. Tighten loose

(7) Loosen the five union nuts (10, fig. 4-93)

nuts and replace damaged valves. Inspect for broken

securing the manifold to the piping and lift out the

pipes and fittings or damaged threads. Replace broken

manifold assembly.

pipes and fittings.

b. Disassembly.

d. Reassembly.

Refer to figure 4-90 and

Refer to figure 4-90 and

disassemble the manifold.

reassemble the manifold.

WARNING

e. Installation.

Reverse the procedures in a.

above.

Dry cleaning solvent, P-D-680 or P-S-

4-97. Carbon Dioxide Vapor Manifold

661, used to clean parts is potentially

dangerous to personnel and property.

a. Removal.

Use in a well-ventilated area as the

(1) Empty the pressure vessels.

fumes are dangerous if inhaled. Avoid

(2) Remove the liquid manifold.

repeated and prolonged skin contact.

(3) Remove the 1/3 union (13, fig. 4-94) and

Do not use near open flame or

nipple (12) from the vapor manifold connection at 2,

excessive heat. Flash point of solvent

figure 4-91.

is 100F.-138F. (38C.-59C).

(4) Remove the tube nut (14, fig.

securing the copper tube to the valve (15).

4-102