MODEL 18 SPRAY GUN

GENERAL MAINTENANCE

SPRAY GUN

PRECAUTIONARY NOTE

1.

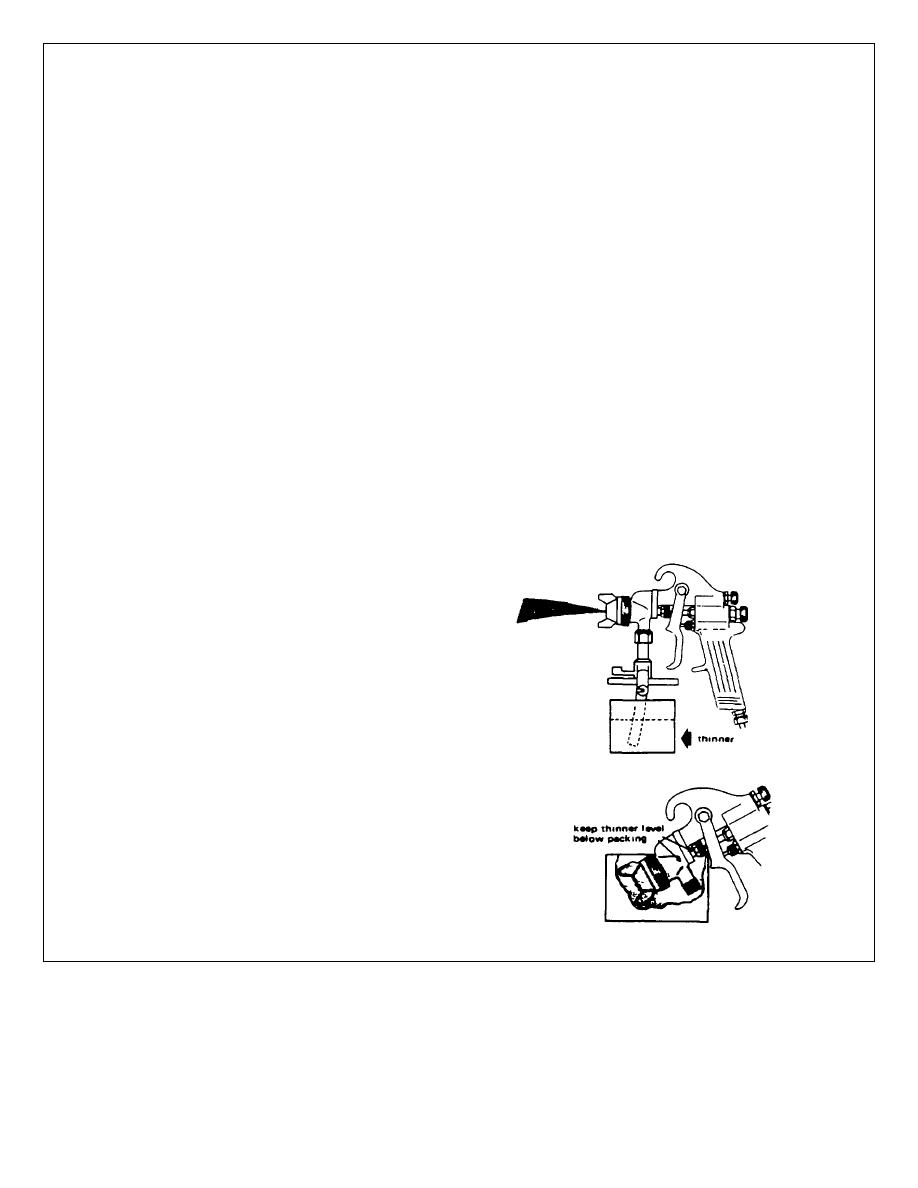

Immerse only the front end of the gun until

All parts on a spray gun should be screwed in hand

solvent just covers the fluid connection.

tight at first; this will avoid the possibility of cross

2.

Use a bristle brush and solvent to wash off

threading the parts. If the parts can not be turned by

accumulated paint.

hand easily, make sure you have the correct parts,

3.

Do not submerge the entire spray gun in solvent

unscrew, realign, and try again. NEVER use undue

because

force in mating parts.

a. the lubricant in the leather packings will

dissolve and the packings will dry out.

AIR NOZZLE, FLUID NOZZLE, NEEDLE ASSEMBLY

b. the lubricant at wear surfaces will dissolve

1.

All nozzles and needles are precision made.

causing harder operation and faster wear.

They should be handled with care.

c. residue from dirty solvent may clog the

2.

Except as described in 5., do not make any

narrow air passages in the gun.

alterations in the gun. To do so could cause

4.

wipe down the outside of the gun with solvent

finishing difficulties.

dampened rag.

3.

To clean nozzles, soak them in solvent to

5.

Lubricate gun daily. Use a light machine oil on.

dissolve any dried material, then blow them

a. fluid needle packing.

clean with air.

b. air valve packing.

4.

Do not probe any of the holes m the nozzles with

c. side port control packing.

metal instruments. If probing is necessary, use

d. trigger pivot point.

only a tool that Is softer than brass.

Coat the fluid control spring with vaseline.

5.

Adjust the fluid needle valve so that when gun is

6.

Caution: Never use lubricants containing

triggered, air-flow occurs before fluid-flow.

silicone.

This material may cause finish defects.

POINTERS ON CLEANING

WHEN USED WITH SIPHON CUP

A compatible thinner or solvent should be siphoned

through gun by inserting tube m open container of that

liquid. Trigger gun repeatedly to flush passageway

thoroughly and to clean tip of needle.

WHEN USED WITH PRESSURE TANK

Shut off air supply to tank and release pressure on tank.

Open vent and loosen air nozzle. Hold a piece of cloth

over the air nozzle and squeeze trigger. Air will back up

through fluid nozzle, and force fluid out of hose into tank.

Next, put enough thinner into tank to wash hose and gun

thoroughly. Spray thinner through the gun until it is

clean. Attach fluid hose to air line and blow it out

thoroughly to remove all traces of materials and to dry it.

4