shown on the back of the gun. This control should be wide

INSTRUCTIONS

open when standard low pressure internal nozzles are used.

FOR OPERATING

Open air Shut-Off Valves. To determine proper

Low Pressure Spray Equipment

pressures begin by adjusting left hand regulator valve (Air

ASSEMBLY

Regulator-Spraying Pressure) to 20 lbs. Now with trigger

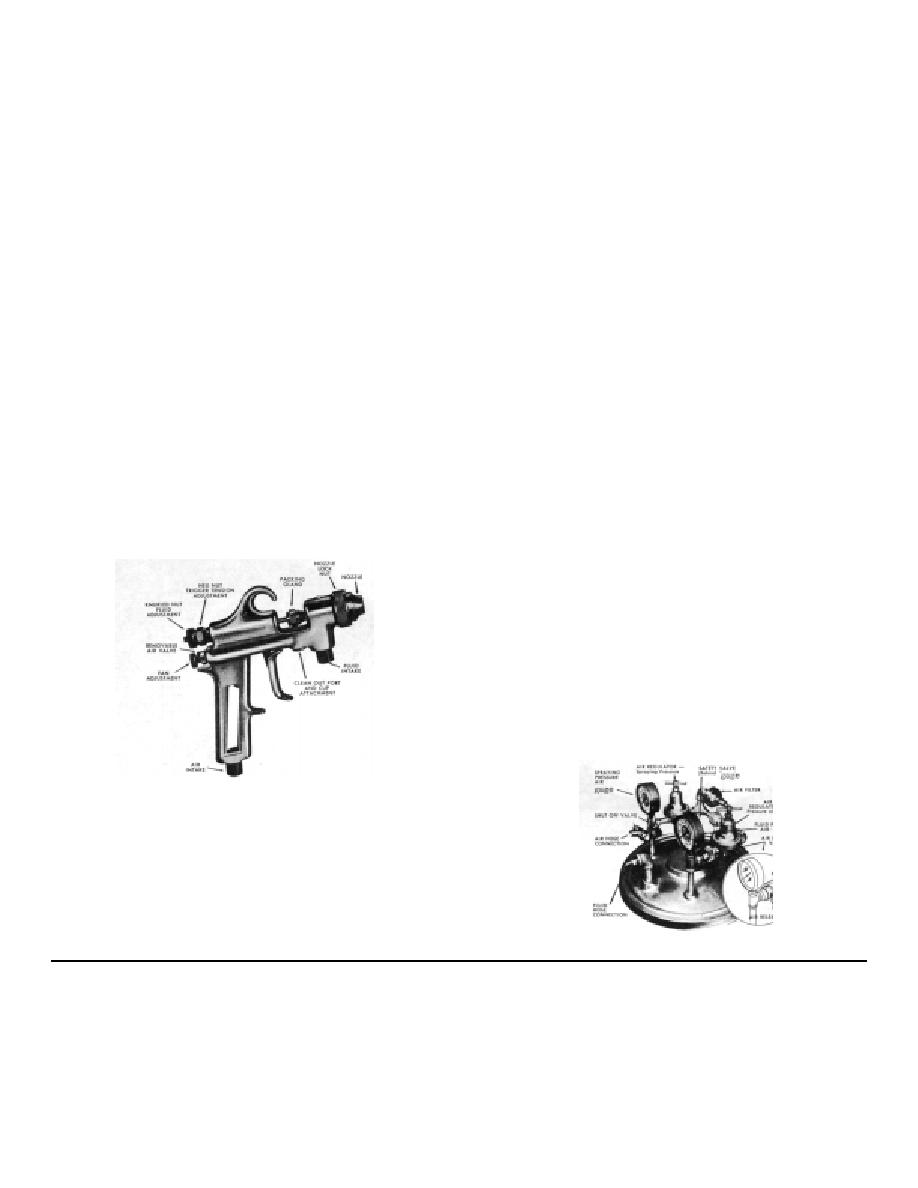

Unpack carefully. Guns, hose with connections, and

pulled bring the pressure on fluid (right hand regulator) up until

wrenches will be found in the tank.

the gun begins to spray. Increase atomizing pressure, then

Screw fluid tube into threaded hole in under side of

pressure on fluid until satisfactory results ore obtained. Keep

control head, beneath the word Fluid. Be sure this post is

the atomizing pressure as low as possible, increasing it only

tight, otherwise air will get into point line and cause a chatter

for greater speed or for heavy viscous materials. For final

or intermittent flow of point at the nozzle.

regulation of material flow, use fluid adjustment on back of

Connect main line air hose (red) to Air Filter.

gun.

Attach one end of paint hose (black) to connection

When working, hold gun six to eight inches from the

marked Fluid on cover. Attach other end of hose to front

object, at right angles to the surface. Point it directly at the

connection of gun shown as Fluid Intake in illustration below.

work and carry it along at a steady speed. Release trigger at

Attach one end of air hose (red) to red connection

the end of each stroke.

marked Air on cover. Attach other end of hose to air

A slight pull on the trigger emits air only, which can be

connection on gun grip, shown as Air Intake in illustration

used for dusting. Pull the trigger all the way back when

below.

painting.

Operation

A little experimenting will determine the correct pressures

Mix and strain material thoroughly.

Paint, varnish,

and speed for 'he work.

enamel, etc., should be at hand-brushing consistency. Nitro-

Cleaning-IMPORTANT

cellulose and synthetic

Open Air Release Valve on tank by pushing slide valve

lacquers spray at lighter consistency.

back (away from reg.) Wait until Fluid Pressure Air Gage reads

Pour material into container. It is not necessary to fill the

zero.

tank-a small container of material can be placed under the

Obstruct nozzle of gun with a rag and pull trigger. The

fluid tube. Hand tighten cover until tank is air-tight. DO NOT

spraying pressure will thus force point out of hose back into

USE TOOLS.

the container.

Close air Shut-Off Valve and Air Release Valve on

Place a small can of thinner in container under the fluid

control head by pushing slide valve forward (toward the Air

tube. Tighten cover. Close Air Release Valve. Close Shut-Off

Regulator-Pressure on Fluid). Note illustration for correct

Valve (red). Remove nozzle from gun. Pull trigger. Fluid

position.

pressure will force thinner through hose and gun, cleaning it

LOW PRESSURE GUN

satisfactorily. Again obstruct nozzle and pull trigger to blow

thinner back in container. Thinner can be saved for use in

reducing.

It is not necessary to disconnect gun from hose or

container, or to remove fluid tip when cleaning.

DO NOT SOAK GUN IN THINNER, as this dissolves the

grease and oil in the trigger action. A drop of oil should be

applied occasionally to the back of the gun and trigger action.

Difficulty may arise due to improper cleaning.

It is not necessary to take the gun apart to clean it. After

the day's work, take the fluid hose off the line and hang it up to

drain.

Take up on nut at Packing Gland periodically. If leak

does not stop, repack the gland.

Remove nozzle from gun.

Adjust right hand regulator (Air Regulator-Pressure on

Fluid) to apply pressure to container. This is the first

regulation of the flow of paint. With about 10 lbs. in the tank

pull the trigger all the way back (the Knurled Nut Fluid

Adjustment should be in the full open, clockwise position) until

fluid flows steadily from the fluid tip. Release trigger.

Put nozzle back on gun. If different spray widths are

required a variable width nozzle should be used (i.e. cone-

fan). Otherwise the nozzle which gives desired width is

recommended. External nozzles are sometimes required on

quick drying materials. The Fan Width Control for these is

NOTE

With internal atomization nozzles air and fluid pressures should be about equal. Not high air and low fluid

pressures as with external atomization high pressure equipment. With heavier materials or when spraying

at a height considerably above the pressure tank (25 ft. - 50 ft.) slightly higher fluid pressure may be

required.

CAUTION:

If atomizing air pressure is set too high, it will back pressure the fluid and starve the gun. Conversely, too

high a fluid pressure may cause paint to back up into air lines and clog the gun.

1