TB 43-0213

Section Il. RUSTPROOFING PROCEDURES

a. Dry Film Thickness Requirements. A five mil dry

10-3. Rustproofing Procedures.

film thickness is required for adequate rustproofing

protection. A 10 mil wet film thickness is required to

CAUTION

obtain a minimum five mil dry film thickness. If

needed, the vehicle can be resprayed to reach proper

thickness.

Do not spray any portion of moving

components, transmission, transfer case,

b. Spraying Pressure. The rustproofing compound

cylinders, pumps, valves, prop shaft,

should be applied to sheet metal and structural

exhaust system, rubber bump stops, brake-

members in even coats. Spraying pressure should be as

drums, brake backing plates, parking brake

low as possible while maintaining an even spray pattern.

linkage, shift linkage, tires, electrical

An acceptable starting point is 40 psi (276 kPa), but

components, engine linkages, or air intake

adjustments may have to be made, due to temperature

systems. Cover all areas with paper where

changes and differences in rustproofing compound.

necessary.

Using too much pressure will waste compound by

causing overspray and excessively thick coatings.

NOTE

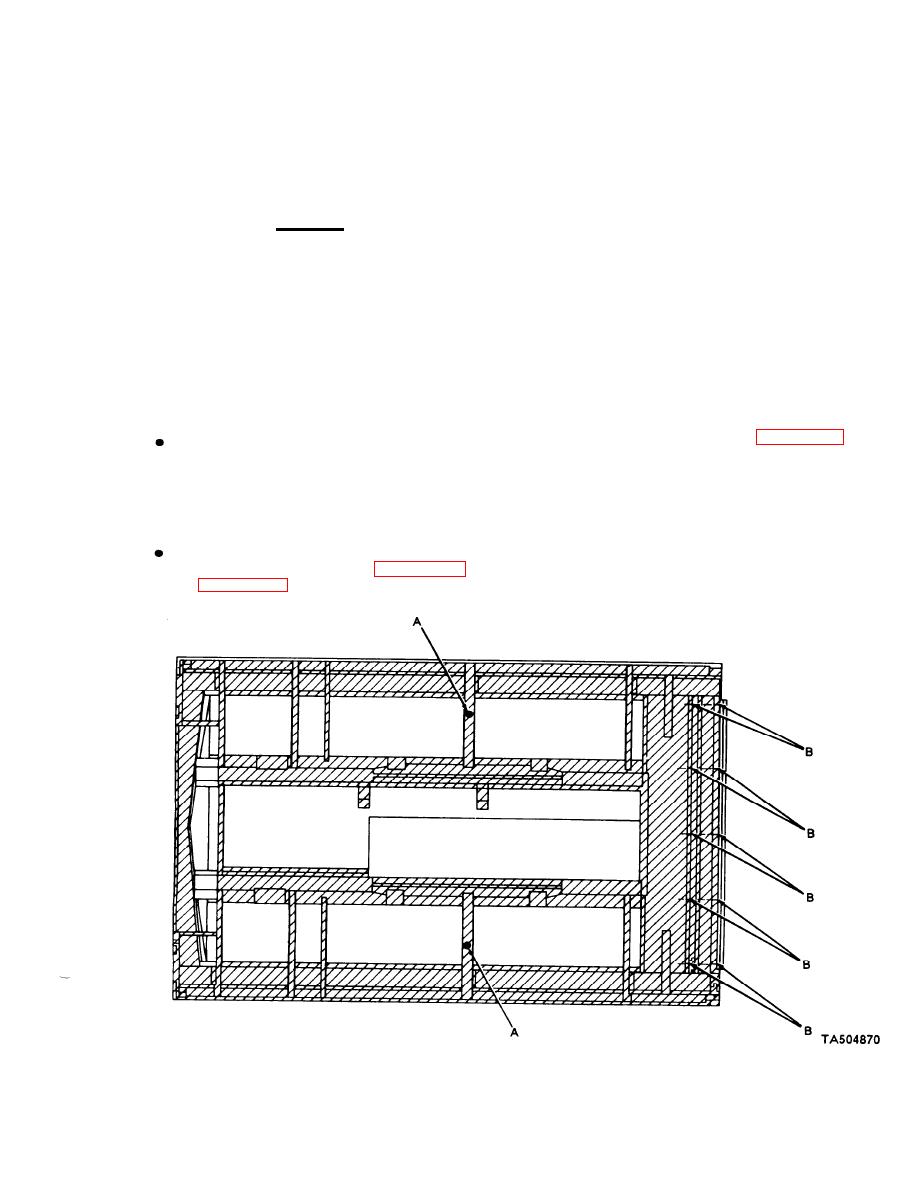

c. Rustproofing Underbody (see Figure 10-3).

There are areas where a 10 mil wet film

thickness cannot be obtained without

(1) Insert 90 degree short tool in holes A and

wasting a large amount of compound. In

spray in all directions to coat the entire interior surface

those areas, complete coverage of the

of the center supports.

surface area is necessary at whatever

thickness is obtainable.

(2) Insert the same tool into holes B and spray

in all directions.

For rustproofing procedures of specific

tanker body items, refer to Figure 10-3

(3) Use short rigid tool to completely cover the

and Figure 10-4.

underbody including all open access areas.

Figure 10-3. Rustproofing Underbody,

10-3