TB 43-0213

a. Wash the interior of framerail structures through

drilled access holes to remove mud, dirt, and rust. Use

of a high pressure washer will facilitate this operation.

Observe the water flushed through the rails to deter-

mine when it is clean.

b. Allow at least four hours for vehicle drying.

Additional drying time may be required if unfavorable

weather conditions exist. Compressed air may be used

to speed up the drying process.

c. Prime and paint those areas showing bare metal,

Allow painted areas time to dry before rustproofing.

TA504909

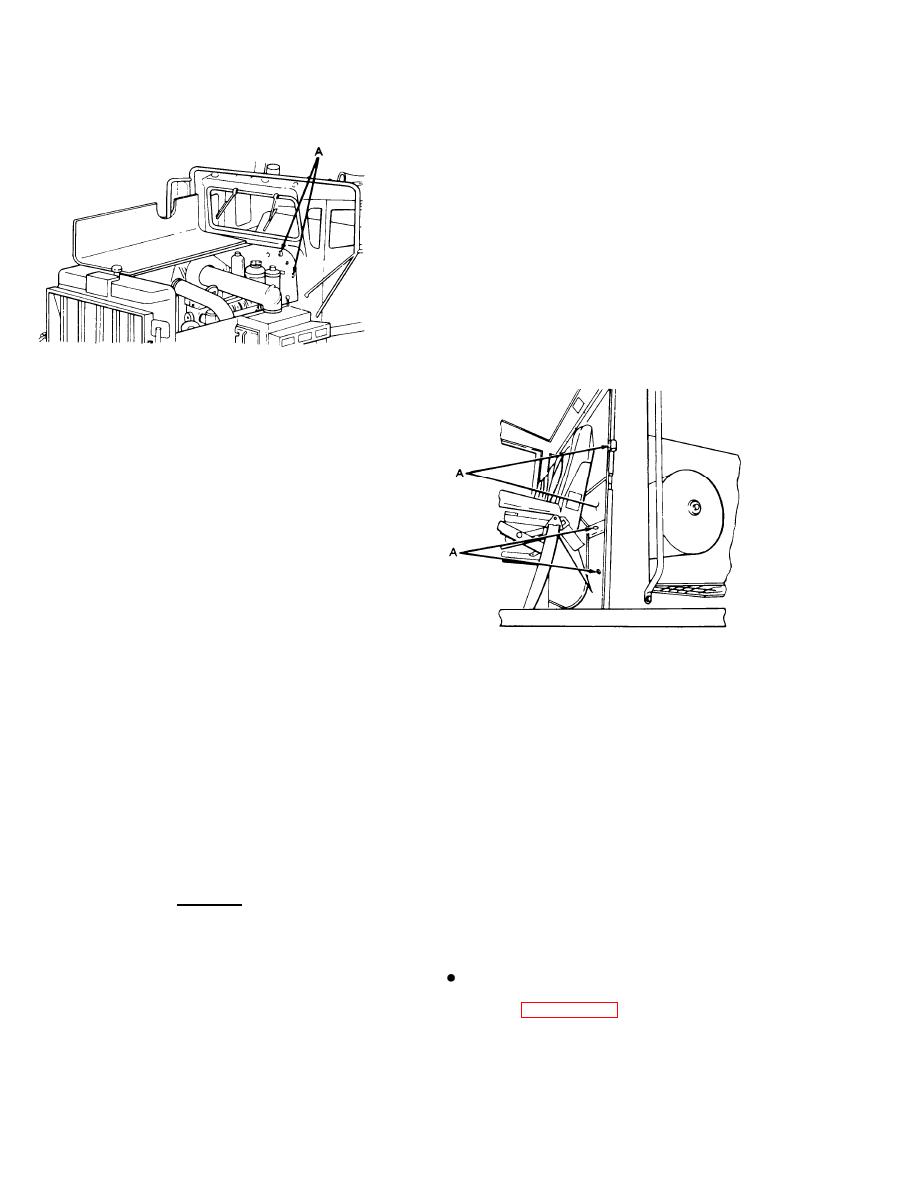

Figure 17-2. Drilling Front Cowl.

17-3. Cleaning Procedures.

WARNING

When cleaning, water may be discharged in

excess of 1200 psi (8274 kPa) from high

pressure water equipment. Serious injury

could result. Eye protection must be worn

to prevent injury.

CAUTION

TA50491O

Figure 17-3. Drilling Rear Cab Braces.

Steam cleaning will not be used.

Section Ill. RUSTPROOFING PROCEDURES

17-4. Rustproofing Procedures.

NOTE

There are areas where a 10 mil wet film

q

thickness cannot be obtained without

CAUTION

wasting a large amount of compound. In

those areas, complete coverage of the

surface area is necessary at whatever

Do not spray any portion of moving compo-

thickness is obtainable.

nents, transmission, transfer case, cylin-

ders, pumps, valves, prop shaft, exhaust

For rustproofing procedures of specific

system, rubber bump stops, brakedrums,

tractor items, refer to Figure 17-4

brake backing plates, parking brake linkage,

through Figure 17-12.

shift linkage, tires, electrical components,

engine linkages, or air intake systems. Cov-

a. Dry Film Thickness Requirements. A five mil dry

film thickness is required for adequate rustproofing pro-

er all areas with paper where necessary.

17-2