TB 43-0213

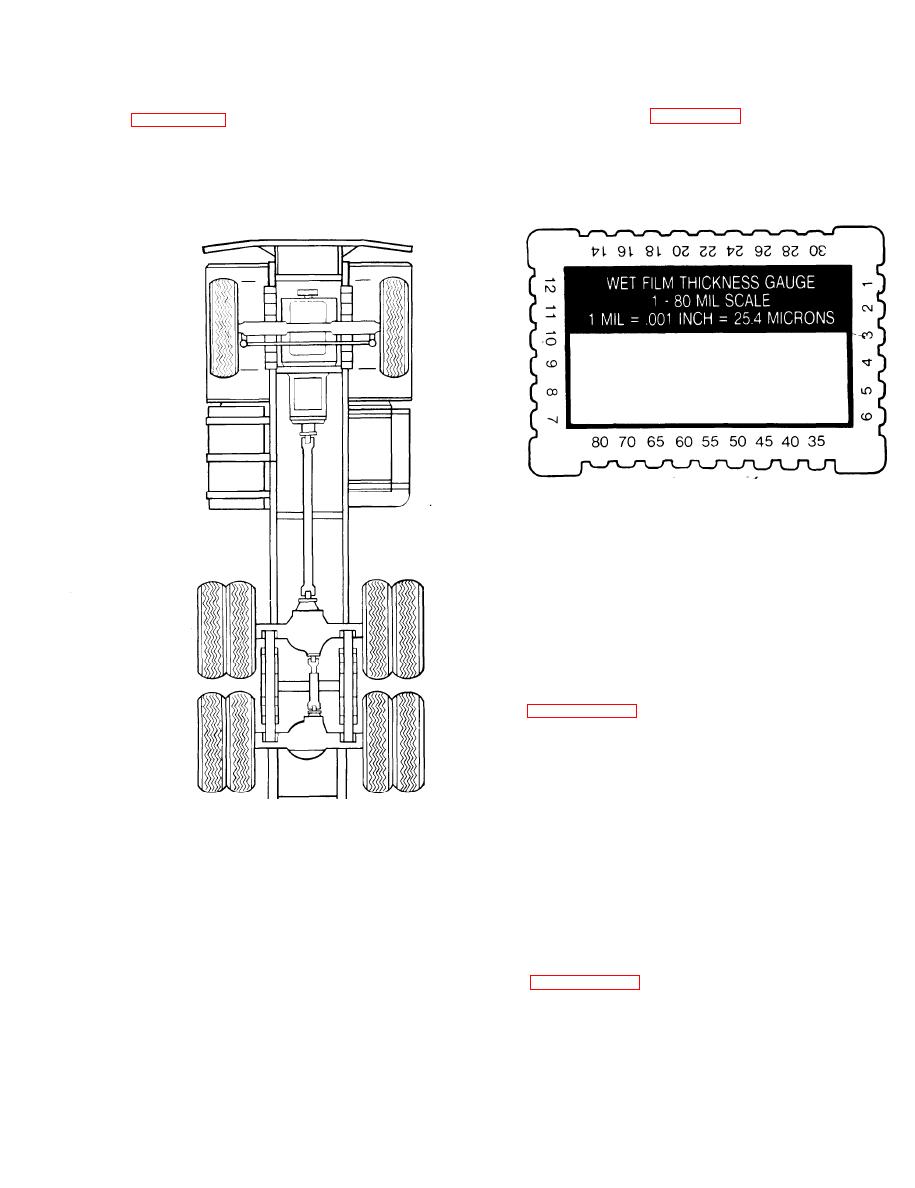

(2) Check wet film thickness with a wet film

(see

(Typical)

Underbody

k. Rustproofing

thickness gage (see Figure 17- 13). A wet film thickness

of 10 roils is required. In areas where a wet film

thickness of 10 roils cannot be obtained or where

(1) Use short rigid tool to completely coat the

thickness cannot be measured, inspect for complete-

underbody.

ness of coverage.

(2) Use 90 degree short tool to coat any areas

inaccessible with the straight tool. These areas include

frame channels and around rear fender flanges.

TA504789

Figure 17-13. Film Thickness Gage.

(3) Check all drain holes to ensure that they are

open.

(4) Check all inspection holes and drilled

access holes to ensure that compound coverage is

adequate. Use of a high intensity inspection light will

enhance this process.

(5) Check vehicle to ensure that no compound

has been applied to prohibited areas (see CAUTION,

NOTE

Plugging of access holes may be delayed

until after vehicle inspection, if inspection

occurs immediately after rustproofing. If

TA504919

inspection is delayed too long, rustproofing

Figure 17-12. Rustproofing Underbody.

compound may drip from access holes.

17-5. Rustproofing Inspection.

b. Plug access holes.

a. Check the vehicle to ensure that all areas

requiring rustproofing compound have been properly

17-6. Component Installation.

and completely coated.

Install all components that were removed in

(1) Check seams, welds, corners, and boxed

areas to ensure that they are adequately coated.

17-5/(17-6 Blank)