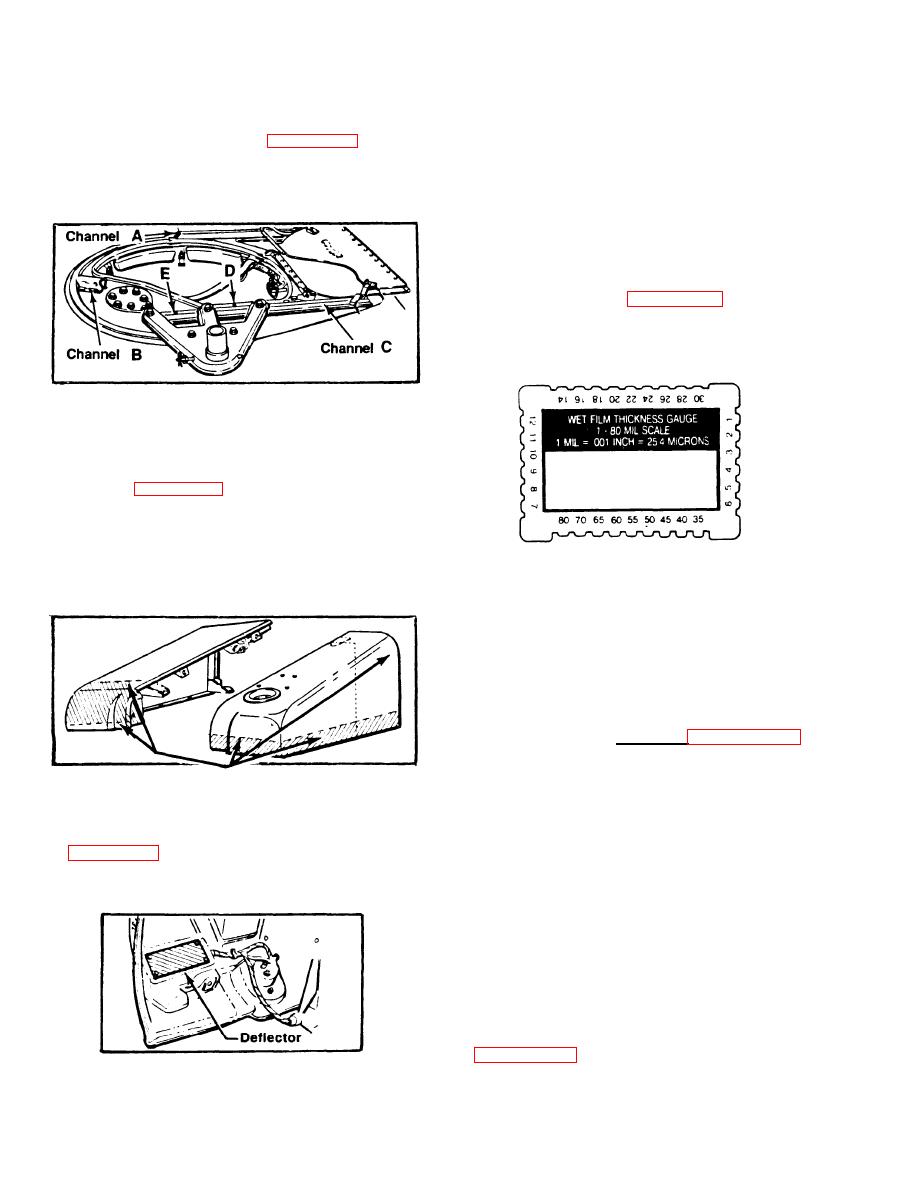

TB 43-0213

Rustproofing Weapon Station Tray Assembly

j

20-5. Rustproofing Inspection.

(Topside) (M996, M1036, M1046, M1025, M1026,

M1043 and M1044 Models see Figure 20-12).

a. Check the vehicle to ensure that all areas

requiring rustproofing compound have been

(1). Insert flexible tool into holes A, B, C, D

properly and completely covered.

and E. Spray in all directions while slowly

withdrawing tool,

(1) Check seams, welds, corners and

boxed areas to ensure they are adequately

covered.

(2) Check wet film thickness with a wet

A wet

film thickness gage (see Figure 20-15).

film thickness of 10 roils is required. In area

where a wet film thickness cannot be obtained or

where wet thickness cannot be measured, inspect

for completeness of coverage.

Figure 20-12. Rustproofing Weapon Station Tray

Assembly (Topside) (M996, M1036, M1046, M1025,

M1026, M1043, and M1044 ).

k. Rustproofing Cargo Shell Assemblies (M996,

M1036,M1046, M1025, M1026, M1043 and M1044

Models see Figure 20-13).

NOTE

Cargo Shell Door Should Be Opened

Figure 20-15. Wet Film Thickness Gage.

(1) Using flexible tool, coat back, side pannels

and all seams of Cargo Shell Mounting

(3) Check all drain holes to ensure that

Components.

they are open.

(4) Check all inspection holes and

drilled access holes to ensure that compound

coverage is adequate.

(5) Check vehicle to ensure that no

compound has been applied to

CAUTION, paragraph 20-

prohibited areas (see

4).

Figure 20-13. flustprooflng Cargo Shell Assemblies

NOTE

(M996, M1036, M1046, M1025, M1026, M1043, and

M1044 ).

l. Rustproofing Headlight Shield Deflectors see

Plugging of access holes may be delayed

until after vehicle inspection, if inspection

occurs immediately after rustproofing. If

(1). Spray both sides of Headlight Shield

inspection is delayed too long, rustproofing

Deflector.

compound may drip from access holes.

b. Plug access holes.

20-6. Component Installation.

Install all components that were removed

in paragraph 20-1 (see TM 9-2320-280-20 and TM

Figure 20-14. Rustproofing Headlight Shield Deflectors

9-2320-280-34).

20-8