TM 5-3655-210-12

e. Cleaning and Inspection. Wipe all parts with a

clean rag dampened in a solvent. Inspect contact points

for burning or pitting. Replace damaged parts, except

lightly pitted points may be filed to a smooth mating

surface.

f. Breaker Point and Condenser Installation.

Reverse the removal procedures in d. above.

g. Breaker Point Gap Adjustment.

(1) Loosen the screws (4, fig. 4-43).

(2) Turn the rotor (12) so the points are fully

open.

(3) Insert a 0. 015 in. feeler gage (11)

between the points.

(4) Use a screwdriver in the adjusting slot

(10) to move the stationary point as needed to get

clearance producing just slight drag with gage between

points, and retighten screws (4) to hold adjustment.

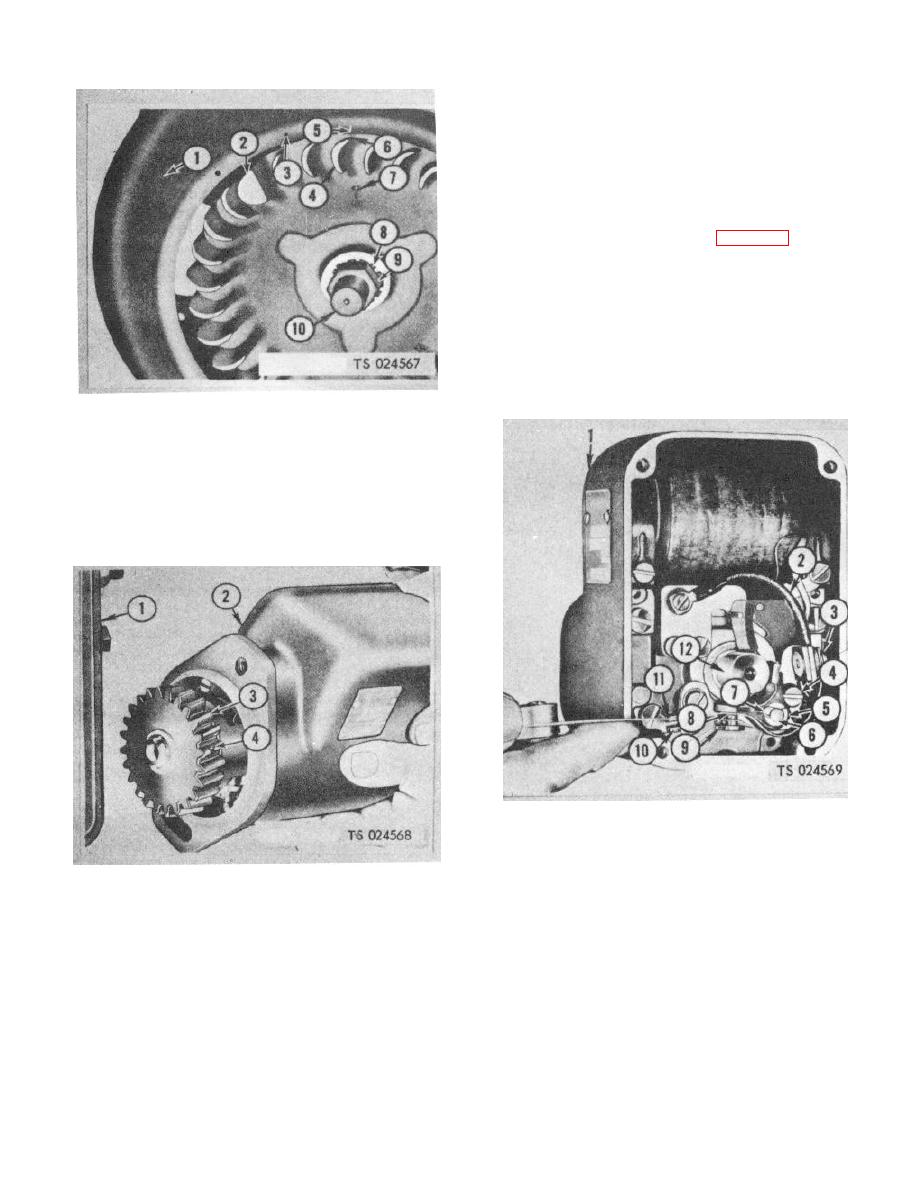

1

Shroud

6

Edging vane

2

Flywheel

7

Flywheel timing mark

3

Running spark advance mark 8

Lock washer

4

Timing vane

9

Flywheel nut

5

Top dead center mark

10

Pin

Figure 4-41. Flywheel timing marks.

1.

Magneto

7.

Lock

2.

Condenser lead

8.

Breaker arm

3.

Terminal screw

9.

Fixed contact

4.

Screw

10.

Adjusting slot

1.

Timing gear cover

5.

Washer

11.

Feeler gage

2.

Magneto

6.

Pivot pin

12.

Rotor

3.

Magneto drive gear

4.

Magneto drive gear timing mark

Figure 4-43. Breaker point, removal and adjustment

Figure 4-42. Magneto gear timing marks.

4-50