(2) Remove the screws (6, fig. 4-55)

securing the wires to the switch to be removed and lift

the wires from switch.

(3) Remove the two screws (12) securing

the switch to the engine control panel and remove the

switch.

(4) Reverse steps (l)to (3) to install new

switch.

4-50. Gage Panel Switches

The power compartment dome light switch (18,

fig. 4-57) and the two vessel alarm bell cut-out switches

(16 and 17) are removed, inspected, cleaned, and

installed in the same manner as all other switches.

4-51. Alarm Bell

a. Removal and Disassembly.

(1) Disconnect the three identification

lights on the bell cover at the connector (fig. 4-56).

(2) Remove the nine machine screws (2,

fig. 4-58) and lockwashers securing the bell cover (3) to

the rear housing (1) and remove the cover.

(3) Refer to figure 4-59 1 or figure 4-59 2

and disassemble the alarm bell.

b. Assembly and Installation.

Reverse a.

above to assemble and install the alarm bell.

4-52. Blackout and Service Stop and Taillights

a. Removal

(1) To remove either blackout or service

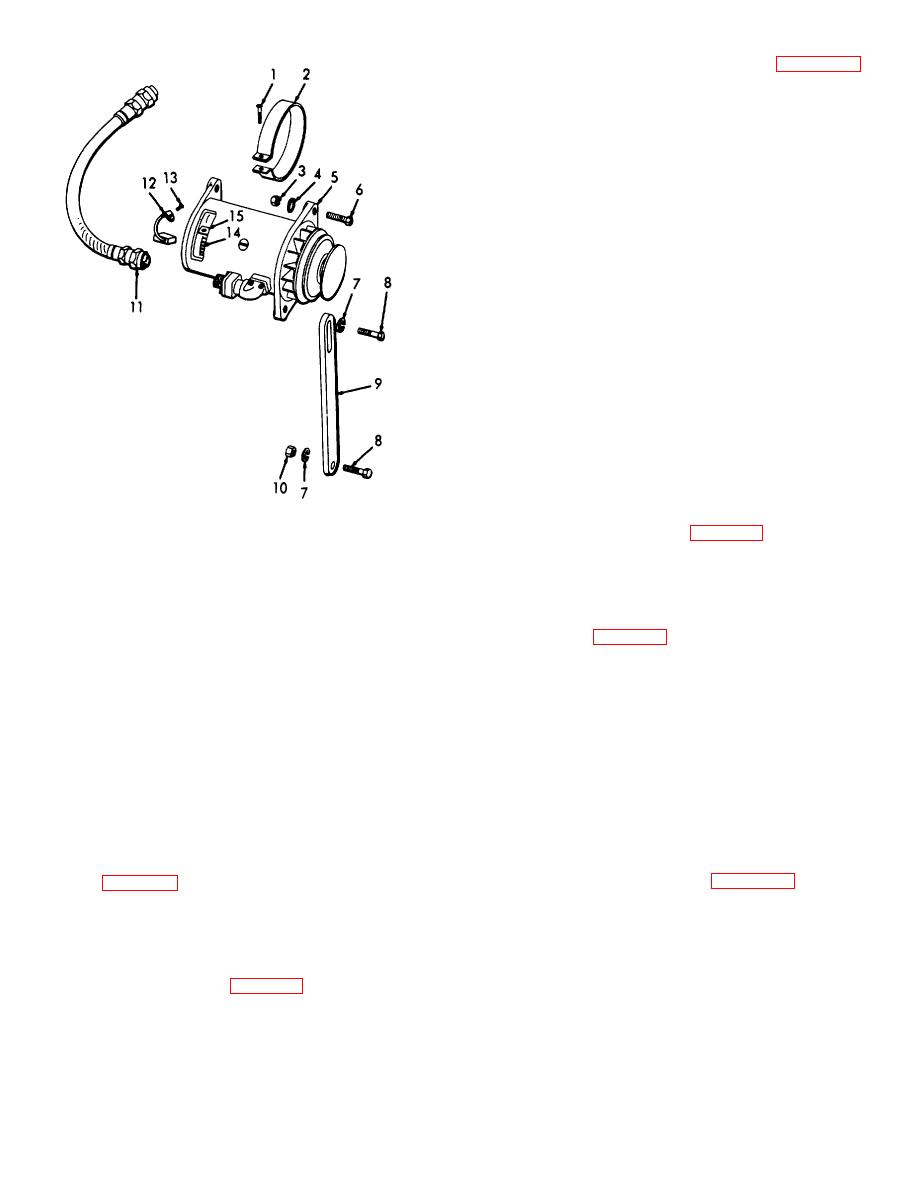

1.

Screw

9.

Adjusting bracket

stop and taillights (11) and 15, fig. 4-60) uncouple wire

2.

Strap

10.

Nut

connectors (14) and tag leads for identification, then

3.

Nut

11.

Wiring harness

remove capscrews (12) and lockwashers (13) to free

4.

IE washer

12.

Brush

blackout units, or screws and nuts attaching service

5.

13.

Screw

units. Reverse this procedure to install.

6.

Capscrew

14.

Lead

(2) To replace lamps, loosen screws,

7.

Lockwasher

15.

Holder

remove door (1, fig. 4-61) and remove defective lamp

8.

Capscrew

by pressing in while turning lamp to left, to disengage

Figure 4-52. Generator brush installation

lamp base from socket, then remove lamp. Install new

lamp by reversing removal procedure above.

NOTE

b.

Installation.

Procedure above is typical for both service and

blackout taillights.

(1) Position the two shock mounts (20)

b. Disassembly. Refer to figures 4-61 and 4-

and starter control (9) on the bracket (18) and secure

62 and disassemble the light.

with the two nuts (21) and lockwashers (22).

c. Repair. Replace all damaged parts.

(2) Connect the wires to the terminals,

d. Reassembly.

Reverse disassembly

refer to figure 4-56.

procedures.

4-49.

Control Panel Switches

4-53.

Clearance Lights

a. General. The gage line heater switches(16

and 17, fig. 4-55), the conversion heater switch (14),

screws (11), door (1), lens (2) and press and turn lamp

the space heater switch (15), the gasoline engine start

left to release. Reverse these steps to complete

and stop switches (11 and 13), the automatic manual

operation. To replace entire light assembly proceed as

control switch (10), the circuit breaker (4), and the

follows:

tractor-trailer switch (5) are all removed, cleaned,

b. Remove door and lens as given above.

inspected and installed in the same manner. Disconnect

Inside trailer body, at light to be replaced, disconnect

the battery ground lead (2, fig. 4-54) before working on

electrical connector by pressing two halves together

any of these switches.

b. Replacement.

while twisting them.

(1) Tag the wire leads on the switch to be

removed, refer to the wiring diagram, figure 4-56.

4-59