TM 5-3655-210-12

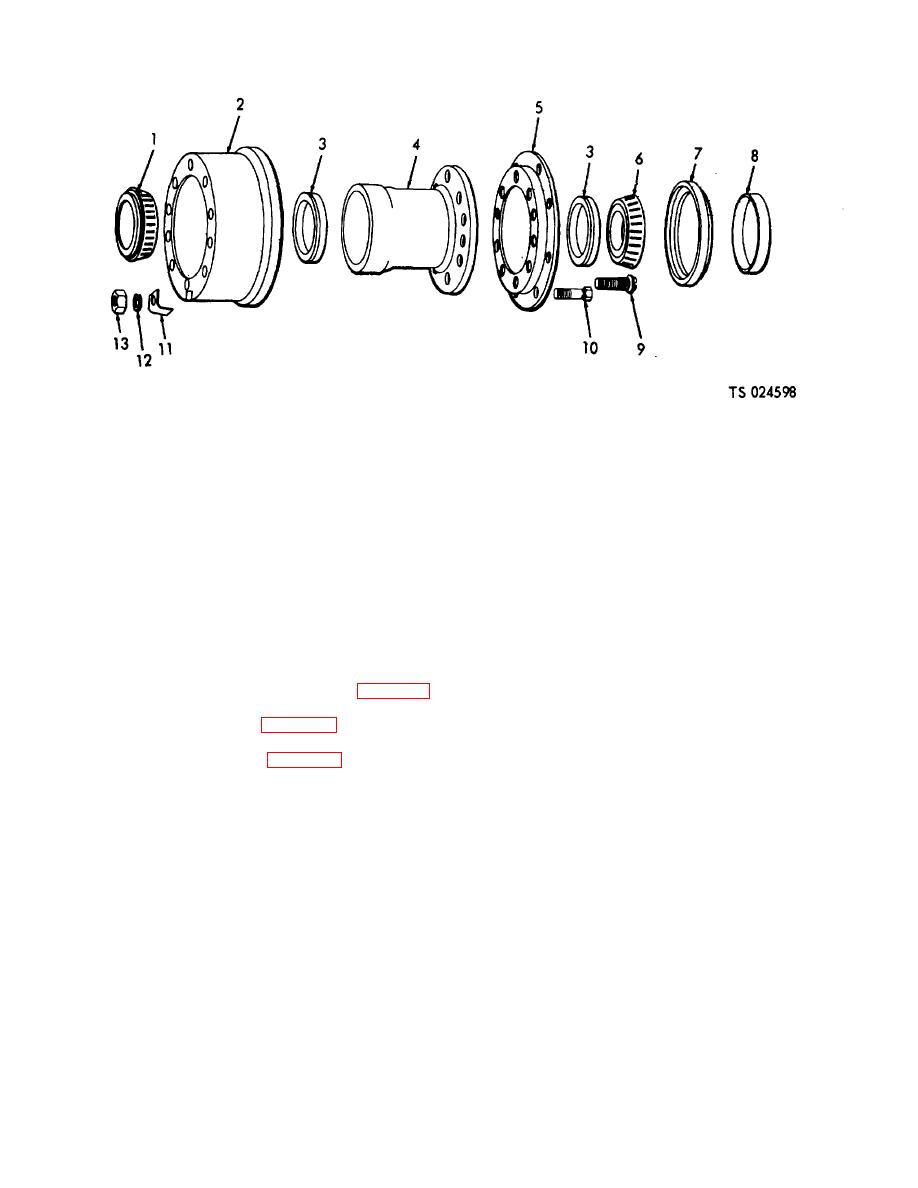

1.

Bearing cone

6.

Bearing cone

10.

Shoulder bolt

2.

Brake drum

7.

Seal

11.

Clamp,

3.

Bearing cup

8.

Wiper

12.

Lockwasher

4.

Hub

9.

Shoulder bolt

13.

Nut

5.

Adapter flange

Figure 4-71. Hub and drum assembly, exploded view.

e. Installation

(6) Position the outer bearing cone (6) on the

axle.

(1) Make sure all the old grease has been

(7) Install the inner retaining nut (7) and

removed.

tighten while turning the wheel until the bearing just

(2) Pack the bearings with lubricants; kneading

seats. Back off the nut one-third turn so that the wheel

the lubricant between the inner race and the cage by

and bearings turn freely.

hand. Coat the inside of the hub and the axle with

(8) Position the retaining ring (8) on the axle

grease to prevent rusting.

(10) and the dowel on the nut(7), and secure with the

(3) Position the rear bearing cone (6, fig. 4-69)

outer nut (9).

and the grease seal in the hub.

(9) Position the gasket (11) and hub cap (12)

(4) Slide the wiper (8, fig. 4-71) into position

on the axle and secure with the six lockwashers (13) and

on the axle.

capscrews (14).

(5) Position the hub (5, fig. 4-69) on the axle,

being careful not to damage the axle threads.

Section XVI. BRAKE SYSTEM

4-69. Description (See Fig, 4-72)

apply the brakes. The system includes connections at

a. General.

the front so the air brake system can be connected to

Air brake equipment on trailers

and operated by the air brake system of the truck or

operates the trailer brakes through compressed air in

tractor towing the trailer. Connections are provided also

conjunction with the air brake system on the truck or

at the rear of the trailer to permit connecting to a second

tractor towing the trailer. As shown in figure 4-72, trailer

trailer. Following are the devices composing the trailer

air brake system consists of the air devices necessary to

air brake system with a brief description of the function

direct and control the flow of the compressed air and

of each device.

those necessary to transform the energy of compressed

air into the mechanical force and motion necessary to

4-78