TM 5-3655-210-12

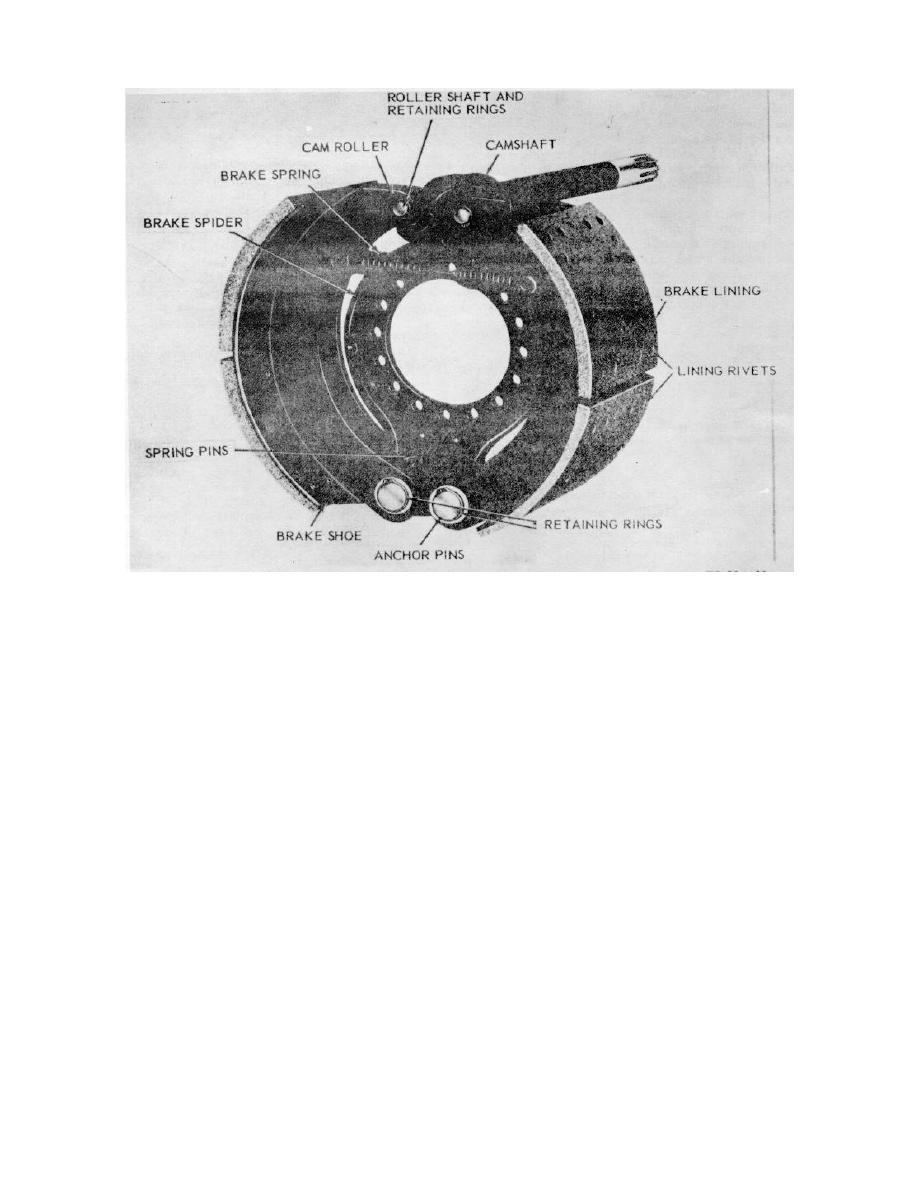

Figure 4-75. Wheel brake assembly

be applied to coverplate, coverplate vent, and exhaust

line is charged. However, remember that under these

port of valve to detect possible inlet valve, inlet valve

conditions, the trailer emergency line will not be charged

guide grommet and emergency piston grommet

until the tractor pressure increases to the point, of

leakage. A combined leakage as indicated by a one-

opening the emergency valve in the tractor protection

inch (2.54 cm) soap bubble in not less than 5 seconds is

valve if installed. Note further that this brake application

permissible. No leakage is permissible at pipe plugs or

is completely released as trailer emergency line

fittings.

pressure reaches approximately 60-65 psi (4.2184.5695

(3) Make and hold a full service brake

kg per sq cm).

application with system reservoir pressure stabilized at

(2) Fully charge tractor and trailer air brake

90100 psi (6.327-7.03 kg per sq cm) with engine

systems. Make several service brake applications and

stopped. A two minute check should result in no more

check for prompt braking response at all trailer wheels.

than an eight pound pressure drop for the combination

With brakes released and system reservoir pressure

vehicle system.

If this check indicates possible

stabilized at 90-100 psi (6.327-7.03 kg per sq cm), with

excessive leakage of valve, soap suds should be

engine stopped, a two minute check should result in no

applied to cover plate, cover plate vent, and exhaust

more than a six pound pressure drop for the

port to detect exhaust valve, valve guide grommet,

combination vehicle system. If this check indicates

possible excessive leakage of valve, soap suds should

4-83