TM 5-3655-210-12

d. Leakage Test.

(1) With system pressure up and actuators in

the released position, check drain slot and around push

rod boot with soap solution to detect possible leakage by

the locking piston grommet.

(2) Make and hold a service brake application,

and again check the actuator drain slot for diaphragm

leakage. Continue to hold the service application and

coat around the clamping ring with soap solution to

detect seal leakage. Should leakage be detected at the

clamping ring, tighten the clamping ring nuts evenly but

only enough to stop leakage.

4-75. Trailer Release Valve Replacement

a. Refer to figure 4-72 and disconnect, cap and tag

the lines to the trailer release valve.

b. Unscrew the valve and pipe nipple from the

relay-emergency valve.

c. Reverse steps a. and b. above to install valve.

4-76. Check Valve Replacement

a. Refer to figure 4-72. Disconnect, tag and cap

lines and fittings to check valve.

b. Unscrew and remove check valve from relay

emergency valve.

c. Reverse steps a. and b. above to install.

4-77. Relay Emergency Valve

a. Removal

(1) Block trailer wheels and drain air from

reservoir.

(2) Remove trailer release valve.

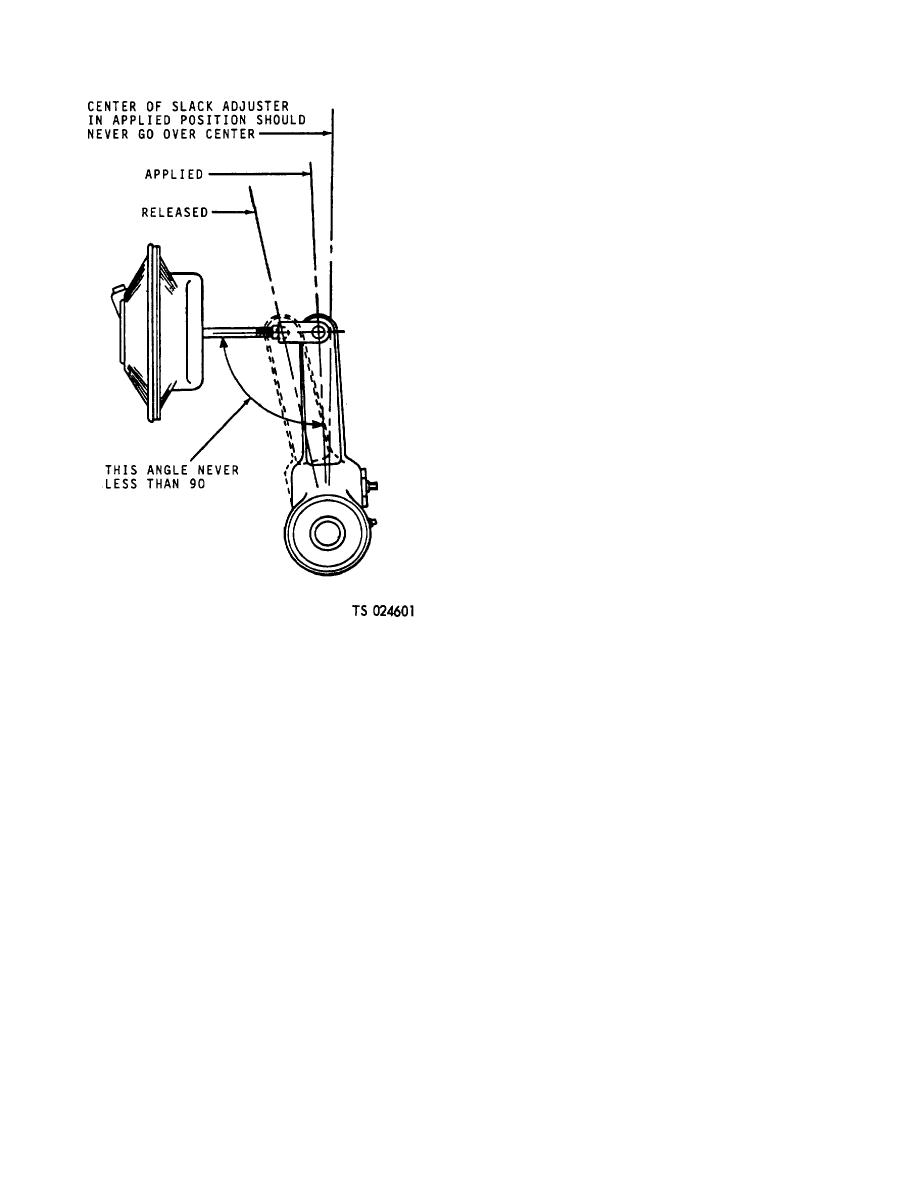

Figure 4-74. Slack adjuster, correct travel

(a) Refer to figure 4-72 and disconnect,

cap and tag the lines to the trailer release valve.

(3) Connect air lines to actuators. Take care

(b) Unscrew the valve and pipe nipple

that the correct lines are installed in correct port.

from the relay-emergency valve.

(4) Adjust brakes to correct shoe to drum

(c) Reverse steps (a) and (b) above to

clearance as follows: Refer to figure 4-73 and adjust

install valve.

each slack adjuster so the wheel brake just drags

(3) Refer to figure 4-72. Disconnect, cap and

slightly, and the angle between the push rod and slack

tag lines to valve.

adjuster arm is greater than 90 when brakes are

(4) Remove mounting bolts and take valve

applied, as shown in figure 4-74.

from reservoir.

c. Operating Test.

b. Installation. Reverse procedure in a. above

(1) With actuator in the released position,

and test as given below.

make several service brake applications and note that

c. Operating and Leakage Test. Check tractor

actuator applies and releases properly.

dash air gage against' a test gage known to be accurate

(2) Disconnect trailer emergency line or throw

prior to performing these tests. 'Connect tractor air lines

trailer into emergency by use of tractor protection valve

to the trailer on which valve is to be tested. Block

and observe that the actuator applies. Drain trailer

wheels or otherwise hold both vehicles by a means other

reservoir and observe that actuator remains applied.

than air brakes during these tests.

(3) Close trailer reservoir drain and fully

(1) Start these tests with no air pressure in

charge trailer air supply. Make and hold a heavy

tractor or trailer air brake system. During the initial

service application (about 5 seconds). Actuator should

charge of the tractor-trailer air brake system, note that

release as service application is released.

the trailer brakes are applied as the trailer emergency

4-82