TM 5-3655-210-12

(4) Unscrew the nipple (3) from the elbow (2).,

(5) Remove the elbow (2) from the strainer (1).

(6) Unscrew the union nut (4) releasing the 1/3

union and the elbow, and remove the 1/3 union from the

elbow.

(7) Unscrew the elbow and 2/3 union from the

compressor, and remove the union and nipple from the

elbow.

(8) Remove the valve cap (6, fig. 4-95) from

the adapter (7).

(9) Lift the outer gasket, valve, and the inner

gasket from the adapter (7) and discard the gaskets.

Replace the new gaskets.

WARNING

Dry cleaning solvent, P-D-680 or P-S-

661, used to clean parts is potentially

dangerous

to

personnel

and

property. Use in a well-ventilated

area as the fumes are dangerous if

inhaled.

Avoid

repeated

and

prolonged skin contact. Do not use

near open flame or excessive heat.

Flash point of solvent is 100F.-138F.

(38C.-59C.).

c. Cleaning, Inspection and Repair. Wash all the

parts in a cleaning solvent and dry thoroughly with,

compressed air. Inspect the valves to see if they have

been seated properly; if not, replace the valves.

NOTE

Loss of capacity in the cylinder filling

unit is usually due to faulty valve

operation.

d. Suction Valve Installation. Reverse procedures

in a. above.

e Discharge Valve Installation.

Reverse

procedures in b. above.

4-105. Packing Nut Adjustment

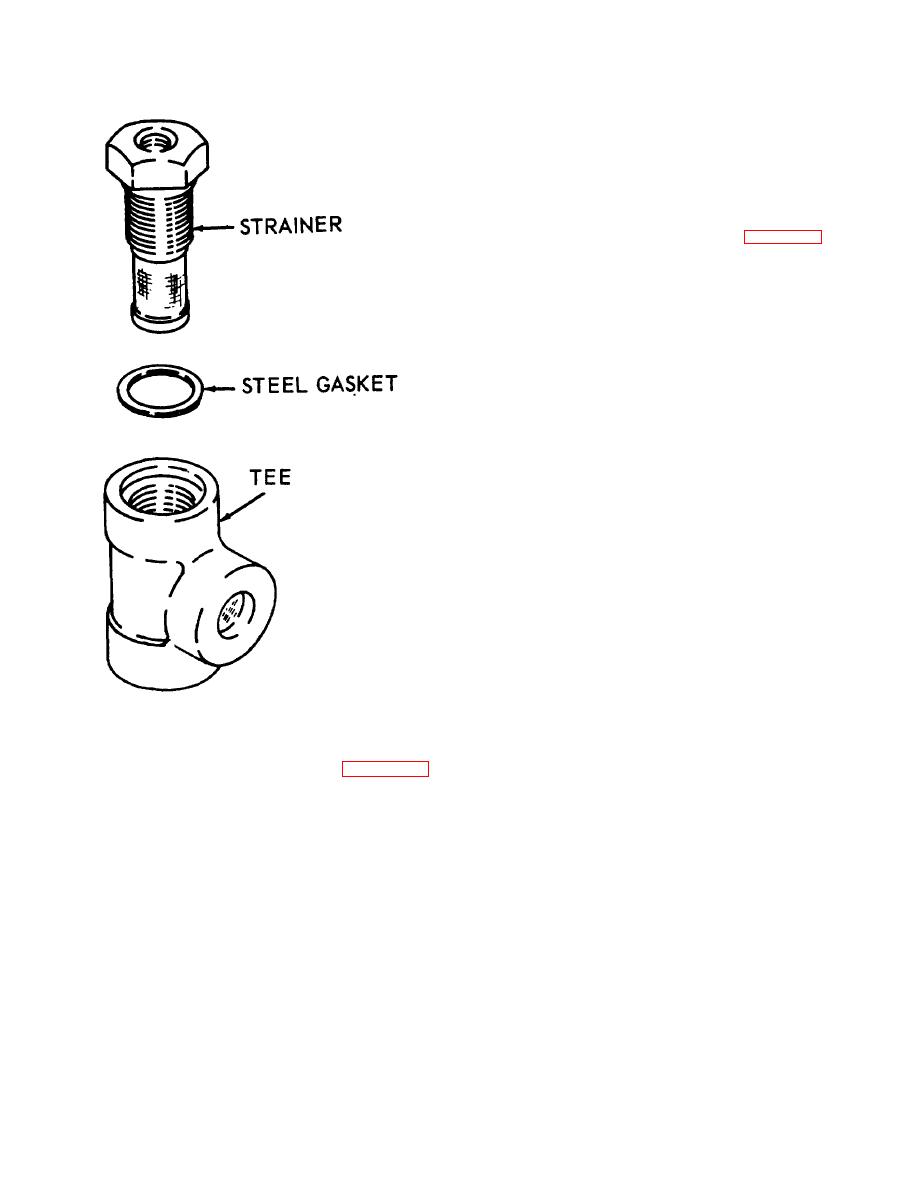

Figure 4-99. Strainer, exploded view.

Leakage past the packing retainer nut (10. fig. 4-

95) is usually shown by excessive spurts of snow past

(2) Unscrew the hose nut (6, fig.

the packing nut. This can be corrected by tightening the

securing the hose (5) to the elbow (2) and remove the

packing nut. It is important that the packing is not too

hose from the valve (30).

tight, as this will cause undue wear. If adjusting the

(3) Remove the rear hose (5) from the cylinder

packing nut does not stop the leak, report the deficiency

filling manifold pipe.

to the proper authority.

4-112