TB 43-0213

protection. A 10 mil wet film thickness is required to

c. Rustproofing

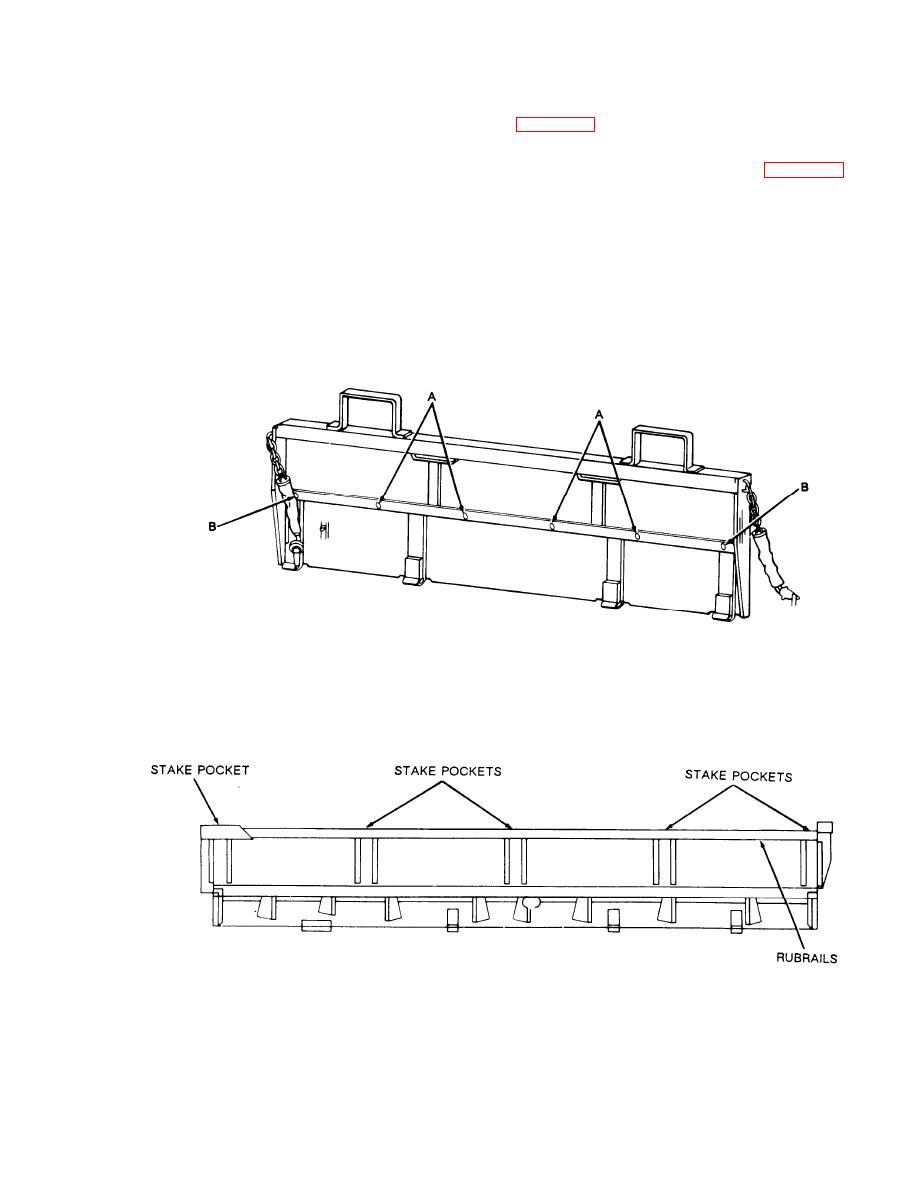

Tailgate

(M35A2C)

(see

obtain a minimum five mil dry film thickness. If

holes A and B and spray in all directions. Plug holes.

needed, the vehicle can be resprayed to reach proper

thickness.

d. Rustproofing Cargo Body (see Figure 8-4).

b. Spraying Pressure. The rustproofing compound

(1) Insert long rigid tool into each stake pocket.

should be applied to sheet metal and structural

Spray while slowly withdrawing tool. Two passes may be

members in even coats. Spraying pressure should be as

required to complete coverage of each pocket.

low as possible while maintaining an even spray pattern.

(2) Use 90 degree short tool to spray the

An acceptable starting point is 40 psi (276 kPa), but

interior surfaces of the rubrail (underneath the ledge),

adjustments may have to be made due to temperature

on sides, front, and tailgate.

changes and differences in rustproofing compound.

Using too much pressure will waste compound by

(3) Use flexible tool to completely cover under-

causing overspray and excessively thick coatings.

body of cargo bed.

TA504857

Figure 8-3. Rustproofing Tailgate (M352AC).

TA504858

Figure 8-4. Rustproofing Cargo Body,

8-3