TM 5-3655-210-12

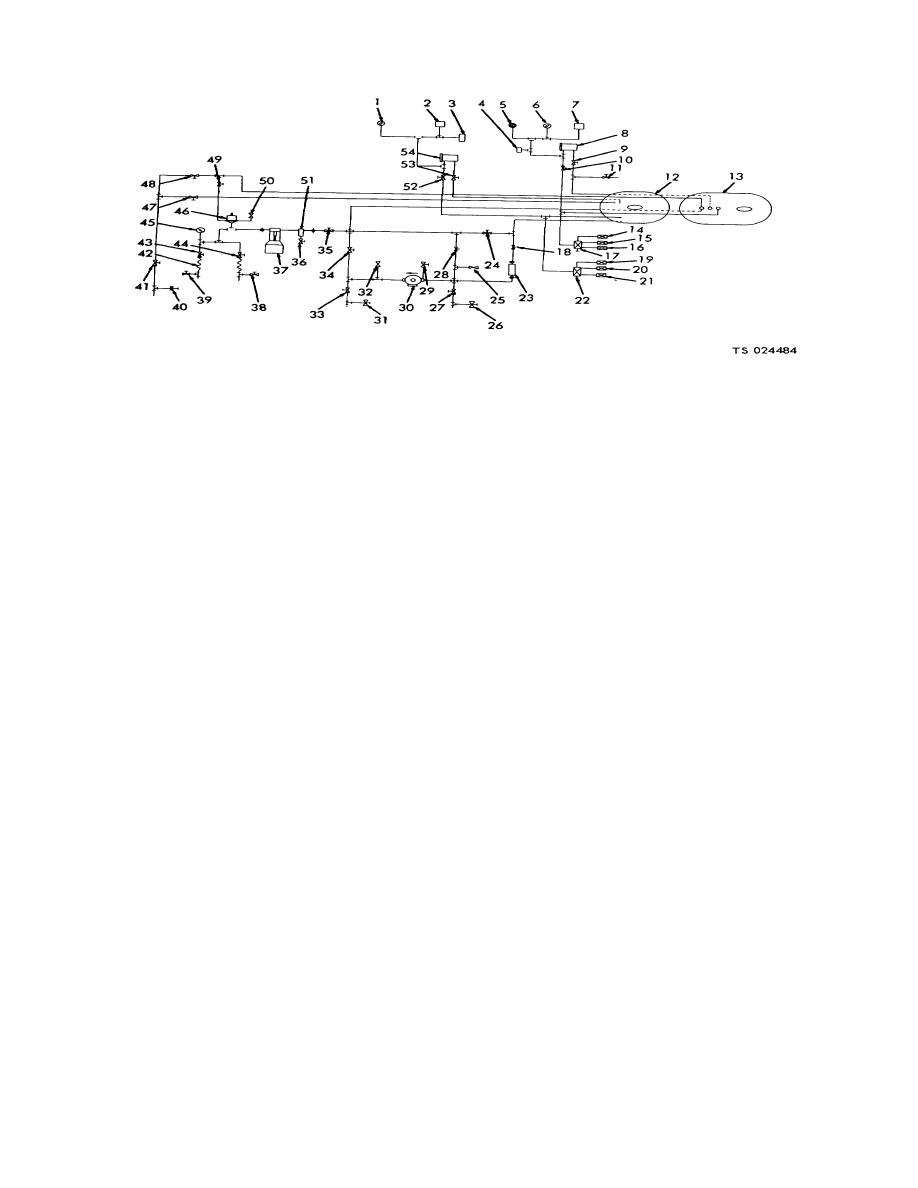

Figure 2-6. Schematic piping diagram.

1.

Tank pressure control switch (conversion heater)

28.

Dehydrator by-pass valve

2.

Alarm pressure switch conversion

29.

Transfer pump bleed-off valve

3.

Pressure gage (conversion)

30.

Transfer pump

4.

Pressure gage (storage)

31.

Transfer hose bleed-off valve (by-pass pump)

5.

Tank pressure control switch (gasoline engine)

32.

Safety relief valve (transfer pump discharge)

6.

Tank pressure control switch (electric motor)

33.

Liquid fill line valve (by-pass pump)

7.

Alarm pressure switch (storage)

34.

Liquid shut-off valve (storage)

8.

Liquid level gage (storage)

35.

Liquid shut-off valve to cylinder fill compressor

9.

Low pressure gage line valve (storage)

36.

Strainer bleed-off valve

10.

High pressure gage line valve (storage)

37.

Cylinder filling unit

11.

Fire valve

38.

Cylinder filling hose bleed-off valve

12.

Conversion pressure vessel

39.

Cylinder filling hose bleed-off valve

13.

Storage pressure vessel

40.

Transfer hose bleed-off valve (vapor)

14.

Bleeder valve for C02 (storage)

41.

Vapor equalizing line valve

15.

Relief valve for CO

(storage)

42.

Cylinder filling hose

16.

Relief valve for C02 (storage)

43.

Cylinder filling valve

17.

Safety vent switching valve (storage)

44.

Cylinder filling valve

18.

Liquid line shut-off valve (conversion)

45.

Cylinder filling pressure gage

19.

Bleeder valve for C02 (conversion)

46.

Pressure regulating valve (cylinder fill)

20.

Relief valve for C02 (conversion)

47.

Vapor return valve (conversion)

21.

Relief valve for C02 (conversion)

48.

Vapor return valve (storage)

22.

Safety vent switching valve (conversion)

49.

High pressure vapor return valve

23.

50.

Safety relief valve cylinder fill

24.

Liquid equalizing line valve

51.

Strainer

25.

Vapor relief valve (liquid line)

52.

High pressure gage line valve (conversion)

26.

Transfer hose bleed-off valve (thru pump)

53.

Low pressure gage line valve (conversion)

27.

Liquid fill line valve (thru pump)

54.

Liquid level gage conversion

2-7