TM 5-3655-210-12

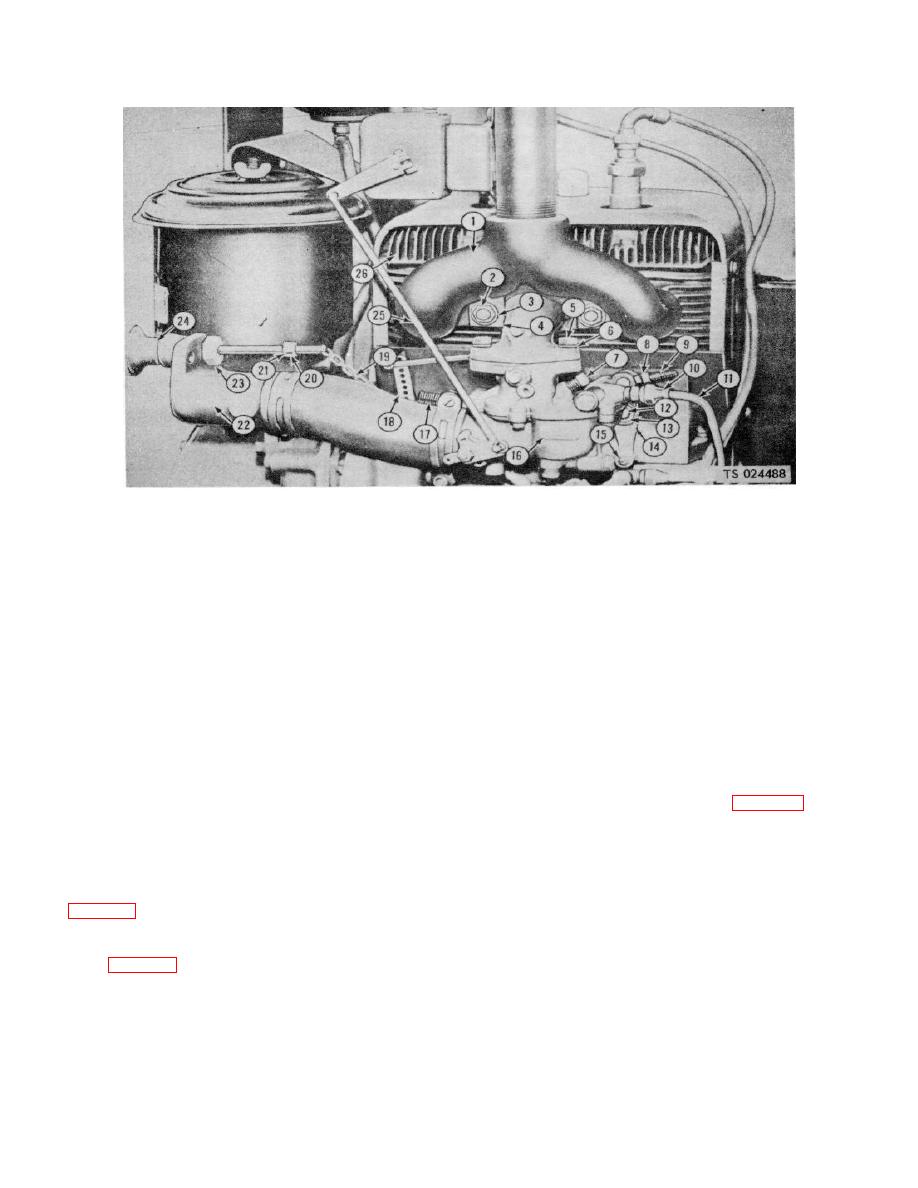

1

Exhaust manifold

15

Screw ser. nos, L1475-T through L-1478-T)

2

Nut

15

Screw (ser. nos, L-1666-T through L-1668-T)

3

Lockwasher

16

Carburetor

4

Saddle washer

17

Spring

5

Capscrew

18

Cross shaft lever

6

Lockwasher

19

Chain

7

Adjusting needle screw

20

Setscrew

8

Adjusting nut

21

Stop collar

9

Governor control rod

22

Air cleaner mounting bracket

10

Tube nut

23

Locknut

11

Fuel tube

24

Governor control

12

Support pin

25

Choke rod

13

Cotter pin

26

Cylinder block

14

Governor control lever

Figure 2-10. Governor controls, installed view

2-6. Normal Conversion Operation

(1) Unlatch the four locks (4, fig. 2-14) securing

Perform the following steps when converting solid

the hatch cover (1) to the platform (3).

carbon dioxide in the conversion pressure vessel into

(2) Lift up the hatch and pull out the block of

liquid carbon dioxide. If the storage pressure vessel

insulation (2).

contains liquid, set the refrigeration controls for

(3) Hold the cover and loosen the two nuts (3,

automatic operation, and engage the refrigeration clutch

fig. 2-15), flatwashers (4), two clamps (5), and the two

(9, fig. 2-3). If the storage pressure vessel is empty,

bolts (6) securing the cover (1).

refrigeration is not required.

(4) Tilt the cover sideways, and pull the cover

a. Position the valves as indicated in Figure 2-13.

and the gasket (2) away from the vessel.

d. Inspect the threads and report any damage to

Refer to Table 2-1 for valve identification.

b. When the pressure in the conversion pressure

proper authority. Inspect and replace a damaged

vessel is 0 psi, close valve 8.

gasket.

c. Open the manway on the conversion pressure

e. Pack the vessel with approximately 4,000

vessel.

pounds (1800 kg) of solid carbon dioxide.

f. Reseal the manway by:

2-11