TM 5-3655-210-12

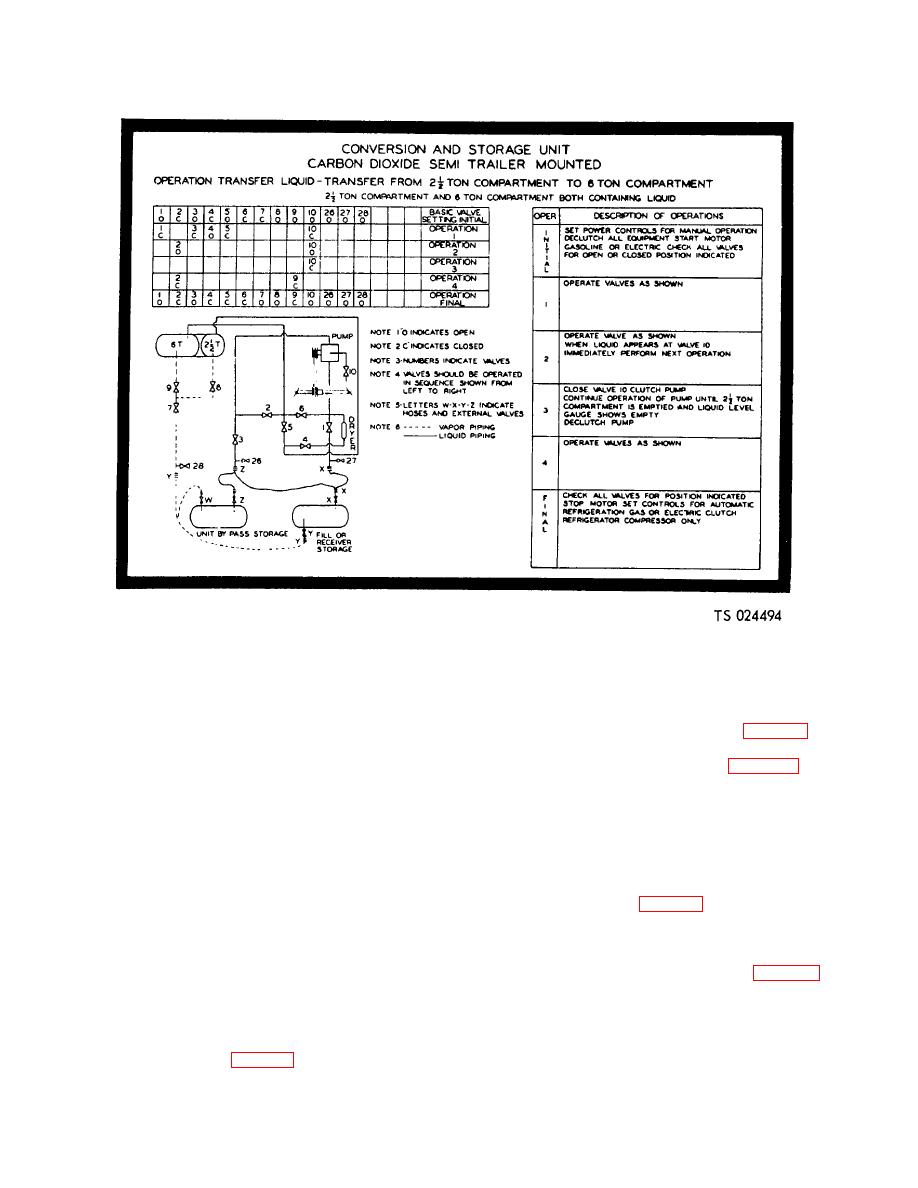

Figure 2-16. Transfer of liquid from the conversion pressure

vessel to the storage pressure vessel.

values are indicated, close valves 8 and 9, and then

(1) Set the driving unit for manual operation

open valve 7. This will allow liquid carbon dioxide to

and disengage all clutches (1, 2, and 3, fig. 2-3).

cover the heater coils at the bottom of the conversion

(2) Set the valves as indicated in Figure 2-16

pressure vessel, and prevent the heater thermostat

and start the driving unit. Refer to Table 2-1 for valve

switch from opening as often as in a normal conversion

identification.

operation.

(3) Close valves 1, 3, 5, and 10 (fig. 2-16).

f. The conversion heater will cycle on and off

Open valve 4. Open valves 2 and 10. When liquid

carbon dioxide appears at valve 10, close the valve and

during the initial stages of conversion. This will occur

engage the clutch to the transfer pump.

since the heater fluid circulating through the coil is not

(4) Continue to operate the transfer pump until

sufficiently cooled by the carbon dioxide, and causes the

the conversion pressure vessel is empty, as indicated by

heater thermostat switch to open and close. The heater

the liquid level gage (6, fig. 2-4).

will continue to operate until the temperature of the

(5) Disengage the transfer pump clutch and

heating fluid, returning to the heater, reaches 73.9C.

close valves 2 and 9.

(165F.). The heater will remain off until the fluid

(6) Set the unit for automatic operation, and

temperature reduces to 65.6C. (150F.). The conversion

engage only the refrigeration clutch (3, fig. 2-3). With

cycle will continue until the pressure in the conversion

all the liquid contained in the storage pressure vessel,

pressure vessel reaches 275 psi (19.3325 kg per sq cm).

the valve should be in the normal position as indicated

At this pressure, the tank pressure control switch will

in Figure 2-13. If the liquid level and pressure is to be

open the circuit, to stop the heater.

g. After conversion is complete, turn off the

equalized in both tanks, close valve 7 and then open

valves 5, 8 and 9. This will provide refrigeration for the

conversion heater switch (9, fig. 2-2) and if the liquid is

contents of both pressure vessels.

to be transferred to the storage pressure vessel, transfer

as follows:

2-15