TM 5-3655-210-12

appears at valve 10, close the valve and engage the

toggle switch (2, fig. 2-2) on the engine panel should be

transfer pump clutch. Continue to pump liquid into the

in the trailer position. The circuit breaker (3), mounted

pressure vessels until they are full. To determine when

on the engine control panel should be ON or in the up

the tank is full, check as follows:

position. Prime the carburetor. Hold the gasoline

(1) Determining Liquid Level While Pumping.

engine START switch (12) mounted on the engine

(a) Liquid Level Gage. The unit is equipped so

control panel up, until the engine starts,; then release

the switch. To stop the engine hold the engine STOP

that the liquid level gages (2 and 4, fig. 2-4) indicate the

switch (11) up until the engine is completely stopped.

contents of the pressure vessels (in tenths of capacity)

b. Set the valves as indicated in Figure 2-13 and

even during pumping. Thus the contents can be

determined by reading the gages and allowing for slight

start the driving unit. Refer to Table 2-1 for valve

time lag.

identification.

(b) Liquid in Vapor Equalizing Line. When

c. Remove the caps and connect the liquid and

filling the pressure vessels, it is usually desirable to fill

vapor transfer hoses (5 and 10, fig. 2-18) or (5 and 10,

them completely. The normal course of the carbon

fig. 2-19) (stored in the storage compartment) to the

dioxide during filling is for liquid to enter at the bottom of

liquid fill line (5, fig. 2-11) and vapor equalizing line (2)

the vessels while carbon dioxide vapor flows out at the

at the rear of the trailer, and to the liquid supply unit.

d. Close valves 1, 3, 10, 27, and 28 (fig. 2-20).

top of the vessels, returning to the tank from which the

liquid is being pumped. When the liquid level in the

Open the liquid fill and vapor equalizing valves on the

pressure vessel rises until it reaches the bottom of the

liquid supply unit.

e. Open valves 1, 2, 7, and 10. When liquid

vapor equalizing dip tube inside the vessel, the tank is

at full capacity.

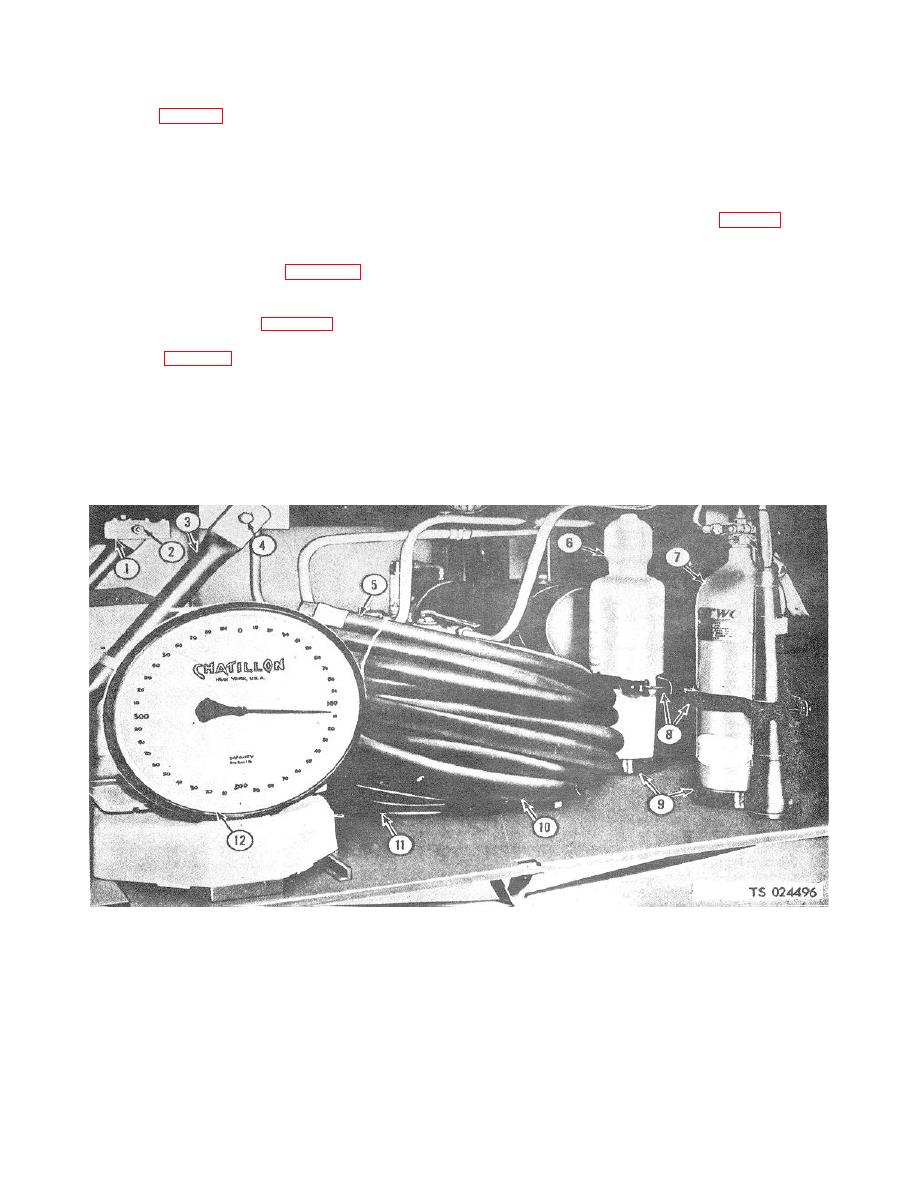

1. Bracket

4

Capscrew

7

Fire extinguisher

10 Transfer hose (liquid)

2. Nut

4

Transfer hose (vapor)

8

Quick release clamp

11 Cylinder filling hoses

3. Brace

6

Freon tank

9

Holder

12 Scales

Figure 2-18. Storage compartment, face view (ser . nos . L-1475-T

through L-1478-T) .

2-17