TM 5-3655-210-12

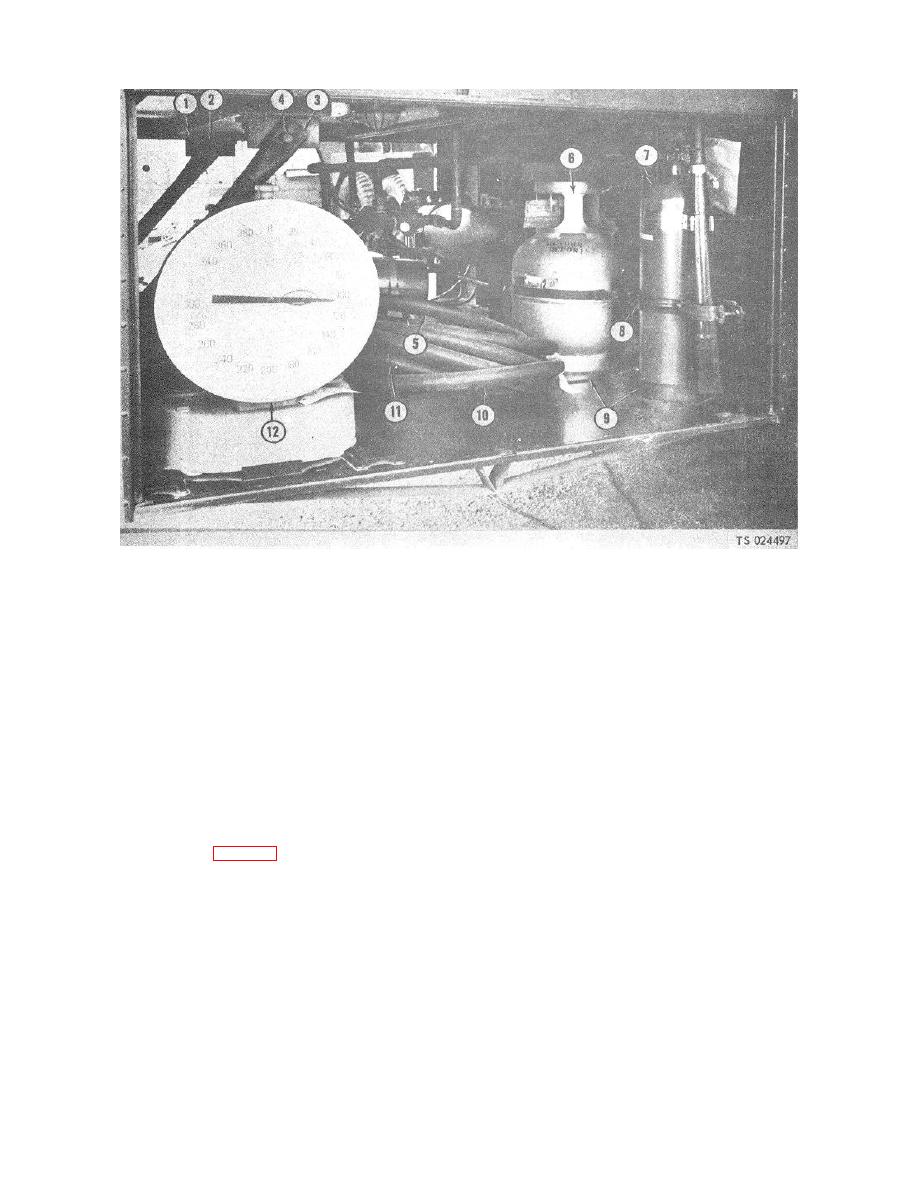

1. Bracket

4. Capscrew

7. Fire extinguisher

10. Transfer hose (liquid)

2. Nut

5. Transfer hose (vapor)

8. Quick release clamp

11. Cylinder filling hoses

3. Brace

6. Freon tank

9. Holder

12. Scale

Figure 2-19 .

Storage compartment, face view (ser. nos . L-1666-T through L-1668-T) .

NOTE

dioxide. Be alert for the indications outlined in (b) and

(c) above, several minutes before this time has elapsed.

If pumping is continued after capacity is

Stop the pump immediately when either indication is

reached, liquid carbon dioxide will enter

observed.

the vapor equalizing line instead of

vaporous carbon dioxide. The cold liquid

(2) Checking for Overfilling.' It is important that the

in the vapor equalizing line will cause that

level of the liquid carbon dioxide inside the pressure

line to accumulate frost, and indicate that

vessel be kept no higher than the bottom of the vapor

complete filling has been obtained.

(c) Pressure Gage. Another method of

equalizing line dip tube. After complete filling of the

pressure vessel and after the hoses have been

determining when the tank is full is to observe the

disconnected, open the vapor equalizing line valve (23,

pressure gages (1 and 3, fig. 2-4). As long as liquid

fig.

2-8) slightly to discharge carbon dioxide to

enters the bottom of the vessel and vapor returns

atmosphere. If the discharge is clear or only slightly

through the vapor equalizing line, the pressure will

foggy, the tank has not been overfilled. However, if the

remain approximately constant. As soon as the liquid

discharge is a dense, white cloud containing particles of

level reaches the vapor equalizing dip tube and liquid is

dry ice, the liquid level in the tank is too high. To

forced into the vapor equalizing line, the pressure will

remedy this, carbon dioxide discharge from the vapor

suddenly begin to rise.

(d) Amount of Carbon Dioxide Required to Fill

equalizing line connection should be allowed to continue

slowly until the dense white discharge changes to a

Tank. If the pumping rate is known, it can be

clean or blue fog discharge.

determined from the liquid level gage reading before

pumping is started how much carbon dioxide will be

required to fill the tank and approximately how long it

will take to pump this amount of carbon

2-18